quote:

Originally posted by Corey Price:

George,

I like the idea you have, but can you please point out a car with this modification? How do you prevent the air bleed line from being a bubble trap at the top of the radiator?

4 members that I know of have converted to using a header tank: captaintobeys, JFFR, PLT-1 and JTPantera. John Taphorn (JTPantera) has extensively modified his cooling system including using a header tank. When mine is back on the road that will make #5. I'm working towards that goal and may have pictures of the modified tanks this week, if the welder doing my work is capable of working with thin gauge stainless steel.

Of course most new cars on the road have header tanks. And most race cars too. I am not proposing anything unusual here.

There already is a vent line to the radiator! It comes that way from the factory. And the radiator IS a bubble trap as it comes from the factory because the vent line doesn't function; giving the vent line a low pressure header tank to vent into makes the vent functional and allows the air in the radiator to flow into the header tank.

The design of the Pantera's cooling system mimics race car cooling systems. It includes small diameter pipes, a two-pass radiator, and two tanks having the appearance of a swirl pot and a header tank, the tanks commonly found in race cars. The design intentionally slows the coolant flow rate down in order to give it time to absorb heat in the motor, and time to extract heat in the radiator. That's why the pipes are sized as small as they are, that’s why the radiator is a two pass design, etc.

Air management in a motor’s cooling system is often taken for granted. Trapped air in the radiator or cylinder heads will inhibit the system’s ability to transfer heat and cool the engine. If the plumbing of the coolant system or the location of the system’s components tends to trap air the trapped air must be removed (i.e. vented). Air released in the cylinder heads as the result of coolant boiling must also be removed from the coolant because air in the coolant will reduce the heat transference properties of the cooling system.

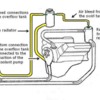

The primary element needed to vent trapped air in a cooling system is a tank connected to the lowest pressure zone in the cooling system, i.e. the suction of the coolant pump. This tank is commonly referred to as a header tank; however it is also referred to by various authors as an expansion tank, a surge tank, or a de-gas tank. Without a low pressure header tank the vents in a cooling system will have nowhere to vent because coolant or air will only flow to a zone of lower pressure. The header tank will be equipped with small connections for vent hoses near the top, and a larger connection at the bottom that can be “teed” into the coolant pump suction line. The header tank is operated with an air space above the coolant to allow for the thermal expansion and contraction of the coolant as it warms or cools, and to allow for surge as the engine speed rises and falls. The header tank is also topped with a radiator cap, making the tank both the fill point and the pressure relief point for the cooling system. The tank is mounted as high as possible within the engine compartment to maximize its efficiency as an air collection tank, a surge and expansion tank, and a coolant system fill point.

Any air that collects within a cooling system after filling and “burping” is normally the result of coolant boiling in the cylinder heads. It is standard race car practice to use a swirl pot (aka a swirl tank) in the cooling system at the coolant outlet of the motor. If correctly designed, the swirl pot will spin the coolant around inside it, making any bubbles or air pockets collect in the middle, rise to the top, and exit via a small bleed tube in the top which is connected to the header tank. Thus the swirl pot keeps the cooling system free of air.

The inlet and outlet nipples on the Pantera’s smaller cooling system tank are configured in such a way there is no mistake it was intended to be a swirl pot. Since a swirl pot is not functional without a header tank to vent to, it is easy to assume the taller cooling system tank was intended to be a header tank. The radiator cap, the large bottom connection and the volume of the taller tank reinforce the assumption it was conceived to be a header tank. These are the two standard tanks utilized in the cooling system of a race car. For an unknown reason the Pantera design team revised the use of the tanks. The header tank became a pressurized coolant recovery tank known as an “expansion tank”; the swirl pot became nothing more than a convenient location for the radiator cap which DeTomaso refers to as a “system tank”. With the header tank converted for use as a recovery tank the radiator no longer had a low pressure tank to vent into so the radiator vent was relocated to the swirl pot (aka the system tank), which was an inept decision since the system pressure in the swirl pot is higher than it is in the radiator.

This change in the cooling system design was ill-advised. The Pantera’s cooling system has a problem with air being trapped in the radiator and it needs a functional vent system. If you want to read more about the design of cooling systems like the Pantera's, refer to Carroll Smith's three books: Prepare to Win (page 122), Engineer to Win (page 170) and Tune to Win (page 97).

-G