Does anyone have experience torquing the rear axle nuts to 400lbs using a torque multiplier tool? I already own the special socket. I wish to back the car onto ramps, remove the half shafts and use this tool to torque the nuts.

Thanks, Blake.

Does anyone have experience torquing the rear axle nuts to 400lbs using a torque multiplier tool? I already own the special socket. I wish to back the car onto ramps, remove the half shafts and use this tool to torque the nuts.

Thanks, Blake.

Replies sorted oldest to newest

The multiplier will need something solid to react against, and the wheel's going to want to rotate. Careful up on the ramps. 400 ft/lbs at the wheel, something's likely to move.

There's other ways...

Thanks for the reply.

Wheel chocks on front wheels, strap the rear wheel to the ramps with compression straps.....who know what else....lower the tire pressure. All to avoid taking everything apart😁.

Let you know what happens. I have read about a gear driven torque multiplier. Maybe my Snap-On buddy can give me some insight.

I always use a high torque air gun, 150 psi and just let it hammer away until it doesn't move anymore, you can actually here when it is tight by the tone of the air gun.

I have done this with everything assembled on the car but it is not easy. The available arc of travel for your socket handle is minimal and requires patience, but can be done.

As for the torque multiplier I have never used one but I do believe it is appropriate for this operation.

Larry

Yea, this is a sucker to do. I didn't have access to a torque multiplier so I had to do it with a 4 foot pipe on a 1/2" breaker bar.

I made a 1/2" thick plate that went over the wheel studs and welded an arm to it, then did it on the car using the car lug studs to hold it in place, the bar turning against the floor.

That is so much leverage that you need to be careful you don't pick the car up off of the floor when you stand on the pipe.

I think I tried it on the workbench like in the above picture but I tore the vise loose from the top it being only 3/4" plywood. I figured on the car was "safer". (Yea, that's the term...safer)

For the weld, you need to go back to your "strength of materials" class and calculate the size of the weld needed with an e60 electrode. It's pretty big and the "stick welder" was on like 150 amps.

I calculated that if I stood on the "arm" being 220 pounds that at 36" when the nut wouldn't turn anymore, it would be about right.

I'm not sure that you can do it accurately with an impact gun at 150 psi air pressure? I was more comfortable with my method, and I don't know if I was "fortunate" not to break a leg or arm, but I got it done.

You do need to be concerned with over stressing the gun, the air hoses AND the compressor itself.

Don't forget that the "impact gun" IS going to "kick" when you hit it with full tank and that you can shatter the gear in the gun. I didn't want to take that kind of a chance. I don't do this every day.

The issue is that there is little procedure for accurately measuring the applied torque without the multiplier.

To this day, I still don't think there are any local shops I could rent or borrow a torque multiplier from?

Maybe the "semi" shops have one but none of the big "semi" guys will even talk to me to this day. They suddenly become mute.

They get like $500 an hour with the "vehicle" on the lift in the shop and helping you takes "food out of their kids mouths".

Caution should prevail. Use the black impact wrench sockets, extensions and components. You don't want even a Craftsman forged socket suddenly shattering on you and throwing shrapnel in your direction. This ain't for "kids" to do. You can get killed doing this.

As I recall, I MIGHT have broken the pin on the 1/2" breaker bar on one, then bent the pipe too? I'm not sure? I prefer not to think about that. Gives me chills thinking about how freakin' crazy I really am? Next I'll be catching bullets in cotton padding? Well, maybe not?

You can twist yourself up really good with doing this too? My chiropractor wants to know exactly WTF I do, being so twisted? I think she means my back but I'm not completely sure that's what SHE meant? Maybe that's why people are afraid of me? Hum?

I have found a multiplier that Snap-On makes. The small unit will do up to approx 650lbs. It has a 1/2 inch input with a 3/4 inch output. I should be able to use my standard 1/2 inch torque wrench set at max. Hopefully I can borrow one from my Snap-On buddy.

i also located a more heavy duty unit at my local rental shop that goes up to 1000lbs. - United Rentals.

Thanks for the replies and photos. Always leaning new things with the Pantera😊.

How much is the rental?

Not sure. They were closed yesterday(Sunday). I will post when I find out.

have you checked with brand name car parts stores

they loan tools for free

don't know if multiplier is one they would have

thinking,. . .

doing it on the car (or any where else) do you have a way to push and hold the socket HARD on tthe nut?

Second person pushing?

That was not an issue for me. The clearance difference (.008") between the socket and the nut kind of locks it in place within reason.

COMMERCIAL tool rentals here do not have torque multipliers. Forget about chain parts stores.

The best bet is to watch ebay for a good used one. They come up occasionally as the big trucks need them just for the lug nuts alone.

marlinjack posted:…A 4 Foot Bar with 100 Pounds on the End will give you 400 Ft/Lbs.

With the Assembly Mounted ON THE VEHICLE; I torqued the Nuts until they would Not Tighten Any Further.

Had a Helper hold the Brakes, and had the Tire on the Floor, with the Full Weight of the Car, to hold from turning. Tighten Beyond the Brake Slipping and the Tire Slips on the Floor, repeat as Necessary. As Tight as You can get it, will be More than 400 Ft/Lbs.

REMEMBER! The Drivers' (On American Cars) LEFT side Nut has the LEFT-Hand Thread!! 'Mass at Rest 'Tends' to Stay at Rest!'

...Last, You are NOT to Re-Use, the Original Nuts! They must be New.

Marlin

Well sure, but it depends on where you stand on the bar. You need room for two feet and be positioned so you don't hit yourself in the private parts. ![]()

I said this isn't easy and it's a wonder I didn't kill or mame myself right?

Also, YOU CAN'T just hold the assembly on two lug studs, you will snap, shear those suckers right off. The studs, not your privates...but . Best to make a plate and use all 5.

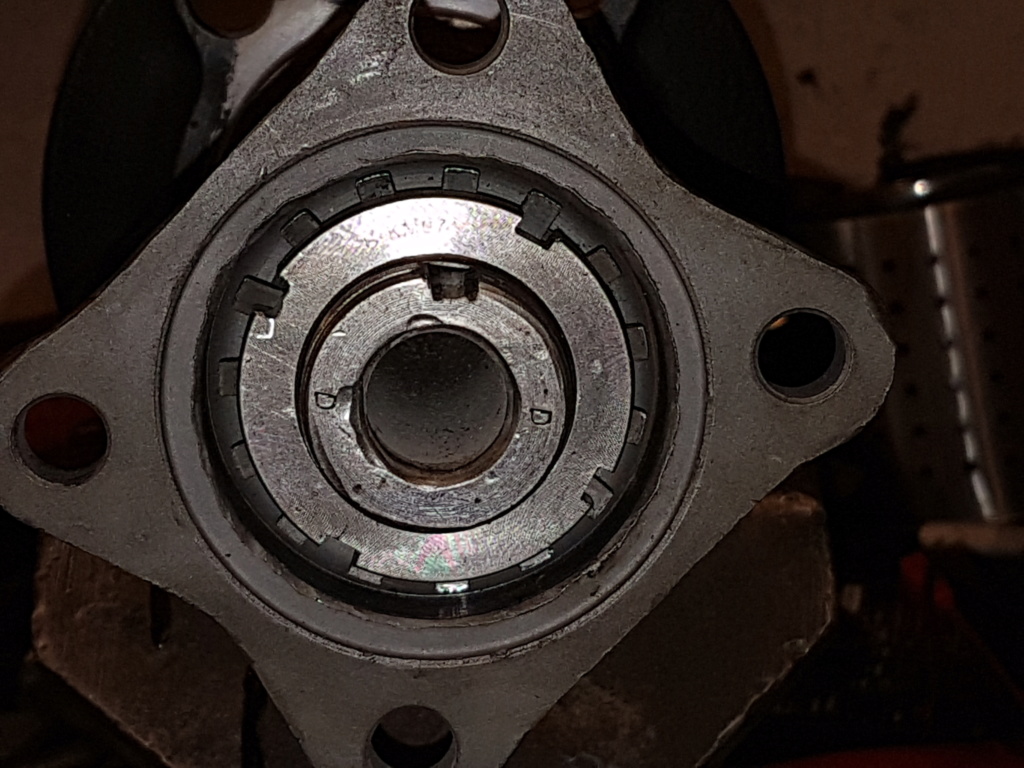

By machining a groove in the shaft and using a SKF nut and a tab lock washer, it becomes unnecessary to tighten to 400 ft.lb, the nut can no longer loosen

It isn’t often one sees an entirely new solution to a Pantera problem, but this one is certainly new to me.

Thank you very much for sharing. Studying the photographs clearly shows how this was accomplished.

Would you happen to have a part number or source for the lock washer you used ?

👍👍

Larry

As well as the P/N for the SKF nut, if it's unique as well. Thanks.

Rocky

René cool as ever!

we need the Part Numbers for SKF and the nice washer!

(i have not done it, but if needed happy to see you in the Perigord!!)

mercy!

matthias