all of the weber aircleaners look bad or don't function well. What is your though about not using any for the short trips to shows etc.

Replies sorted oldest to newest

Weber air cleaners on a V8 engine do not last long. What happens is that the natural fuel reversion soaks the filter element and will catch fire on a restart.

Generally speaking you never use filter elements on 48ida's on a V-8. It just doesn't work.

Use screens and since air flow restriction is a function of surface area, try to maximize the screen surface areas.

I have a bunch of friends running them on 289 Cobras. One of them ran them without screens on his Cobra which he drove regularly for 28 years without anything on the stacks at all.

If you notice, the Group 4 factory race cars that ran Webers used extended velocity stacks that wound up around 5" high in total. That did two things. One was to change the torque curve of the engine somewhat to make using 44mm "auxiliary venturis" more useable and 2) it kept the "cloud" of fuel vapor within the velocity stacks rather then having it wonder all over (for the most part anyway).

It is possible to limit the reversion, but not to completely eliminate it with revised cam timing. Jim Inglese initially experimented with that and basically for the Cleveland there is one cam, a hydraulic lifter one still offered by CompCams that they refer to as the "Weber Cam".

The problem with that one is it doesn't entirely eliminate the reverson and it kills around 100 hp that ordinarily would be available in a conventional longer duration, bigger overlap design.

The magic number with a Cleveland and dealing with reversion is limiting overlap to under a total of 28°. If you look at the timing specs on a stock Ford CJ cam, the overlap listed is right there at 28°. So some guys still running that cam and adding Webers have no idea WTF I'm talking about with either the reversion or air cleaner issues.

"C'est la vie", say the old folks. It goes to show you never can tell- Chuck Berry. ![]()

Attachments

I like your answer and agree with all you say. Weber’s are just too cool to cover and the relatively few miles most of us drive these cars can’t eat up our motors from the rust.

Famous last words?

Tom

That last sentence was to say from dust, not rust.

Speaking of rust, my car has not been washed in the 43 years I’ve owned it, but got wet one time from an unexpected rainstorm. It’s pretty clean.

Attachments

Those little screens on top of Webers are often called 'Bird Catchers'. They also come in handy for stopping urchins from dropping pennies or marbles in open Webers. Air cleaners catch all kinds of debris.... Note- anyone that uses air cleaners on Webers should avoid paper air filters due to the reversion mentioned before. PAPER filters will soak up gas from the reversion, and then you're one backfire-when-cold from a stack fire. So I especially recommend a fire extinguisher on Weber-equipped engines. DeTomasos should carry one just for insurance.

The Pantera has a similar "air chamber" created by the location of the engine and transmission as the GT40's do.

It is much less likely to suck in candy wrappers, squirrel tails or road pebbles then a front engine car does.

The first time I heard the word "urchin" used was on an episode of "Firing Line" where Bill Buckley and Gore Vidal were going at it heavily as usual. I gathered that it was largely a Roman expression that was used to describe unfavorably non-Italians that lived in Rome and were grab and run gangsters.

In using it here once, it was taken by some as a racial disparaging remark against Italians. It has since been dropped from my vocabulary use list. For me, that's a difficult loss since my usable vocabulary is barely 100 words now as is?

It isn't just paper filter elements that absorb the "atomized fuel" it is the cloth fabric and foams as well. The foams don't even burn, the seem to just instantly vaporize.

The frustrating thing is that IDA's have been run on other engines with filters with no issues. The 911-s Porsche is a good example and there are bunches of Lamborghinis like the Miura S and Ferrari 365 GTB Daytonas that were built with them.

The significant factor here is that V8 engines naturally have a reverse pulse into the induction that a 4, 6. or 12 cylinder engine does not produce. I don't know about the 10's in the Vipers though?

When you have a single intake plenum with a single or even multiple carb induction on a V8, the reverse pulse is used to push fuel into the next charging cylinder. IDA's use an individual runner intake sysetem.

Incidentally, the first induction system used on the 69 Shelby Boss 302 Trans Am race car also used an individual runner induction system using two Holley Dominator carbs mounted sideways and had the same reversion issues. The dual Autolite In-line carbs using two on the same engine...same thing...reversion.

The Pantera actually has an advantage here with an IR system in that it has enough room available over the top of the carbs to use taller stacks to retain the vapor cloud within the stack. Very much like the GT40's in that respect.

The IDA was never conceived of as a "street production" carburetor. It was conceived of by Carroll Shelby in order to put on his Cobras so they could have the same advantages of those "Eye-talian" cars did.

They were financed by Ford and built for Ford by Weber. That continued with a very limited set of 58 IDA's also built for Shelby to run on the Mark II 427 GT40's to "beat Ferrari's Ass" at Lemans. The big ones never quite worked out though probably because of this reversion issue and are now VERY valuable antiques and collectables.

Does anybody know when the 48IDAs were first produced and applied to cars?

At the very first application they were 46 IDA's and show up in 1962 as sand castings. Some time in '63 they became 48's and shortly after became pressure cast.

I believe though that the first sand cast versions were called IDF's.

Initially they were serial numbered and those are what you would find on Cobras from the '60s.

The versions used on the Panteras were the '70s versions with date codes on them.

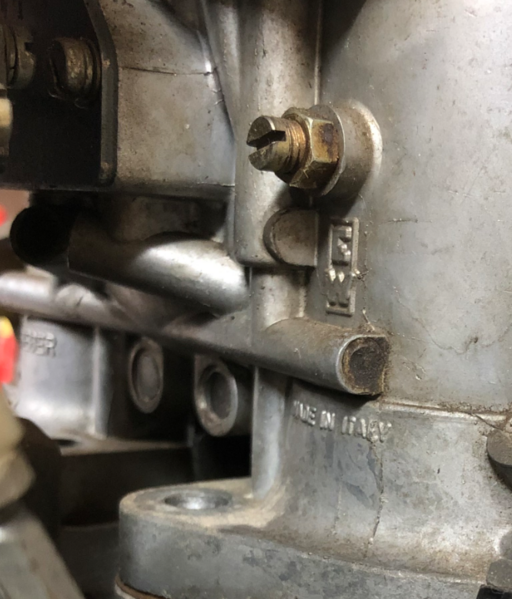

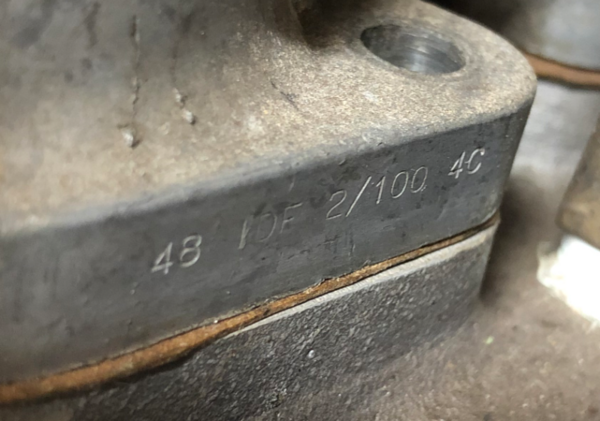

My Italian built Webers have 48 IDA 4 1J stamped on them. They were bought from Hugh Kleinpeter who raced them in 1974, and have been on my car ever since. Can anybody interpret the stamp?

Attachments

Yes. They are 48IDA 4's, which are the last iteration of the IDA. The only difference with the "4's" v "1's" is the "auxiliary venturi". (I've never seen 2's and 3's). That's the changeable choke in them. The first two IDA's were listed as being for the GT40 and were built/assembled with 42mm "chokes". The "4's" were built with 37mm chokes.

The 1J is the date they were made. October 1971.

It's mostly the "Cobra" guys that are looking for '60s dated carbs. Until maybe 20 years ago, no one cared. The only differences are the dates since they are all of a modular construction.

The biggest user of them at that point were VW's mostly in Dune Buggies.

They are all made in Italy up to somewhere in the '80's or '90s when they were made in Spain, then somewhere in this century had the country completely blank.

The only real difference is that the top and bottom were originally held together with a stud and nut on top. The Spanish ones replaced that with just a bolt. The other differences are just the size of the choke they came with and the calibration, i.e., fuel jet, air jet, emulsioln tube, idle holder and idle fuel jet, which are all almost infinitely changeable.

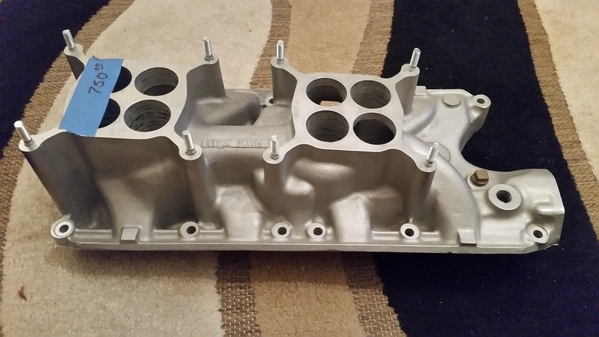

The unique component to your setup is the intake manifold which is unique to the Pantera racing program in Europe where multiple carburetion was legal in the factory classes.

Speculation on production numbers of that manifold are probably 100. Where the rest of them are, no one knows. Only a few have ever shown up for sale.

Carb copies are now being made in China with no indication of where they were made. Some are being bored out to 51mm mostly to use on rotary Mazdas now.

One of mine has a separate bolt-in choke mechanism. It seem that choking only one of four is sufficient for cold starts.

Mine do not need a choke. Two or three pumps cold and it fires up.

Some "tuners" change the accellerator pump check valve for a smaller orifice.

I remember during my initial "tuning" I had them reduced down to a .5. I ran out of time and light that day and put the car away for the night. The next day when I went to start it cold, it wouldn't fire. It seems that I had reduced the pump shot down too much.

The pumps are "heavy" as supplied new. I think they are stock with either 2.0 or 1.5's? If you leave them stock, you don't need a choke to cold start the engine.

Lots of these details had to be learned by me the hard way. NO ONE knew these details OR just wouldn't share them in '77 or '78 when I was crazy enough to do this on my own. I did have the help of Jim Inglese though. He "leant" me all the fuel jets and air jets I needed with the understanding that when I got the tune right I would only share the information with him.

It seems that the Clevelands are from a different "Universe" then the 289's and 427's are and I was the test mule. There were some like Kleinpeter that had the information but to most back then that was all proprietary information and kept under lock and key in a safe.

I fussed with those Kleinpeter Webers for years. The two-progression hole version was never good near idle, so two years ago I bought a new three progression hole set and all is finally well. I still own a bag full of jets etc.

I have researched the Holman Moody built DeTomaso Weber manifolds extensively and found several of answers regarding their numbers. No two were the same. Because they are rather thin walled and fragile, they tended to break easily during installation. No telling how many survived. I know of two, one of which is mine. Hugh Kleinpeter had his machined into two halves so the two sides were independent of each other.(see attached)

I would not buy a Chinese set of Webers, if that's where they come from now. My experience with Chinese parts has not been good.

Attachments

Thanks, Doug. I have a brand new set of 48DCOEs in the shop, and a partially completed side-draft intake manifold. Then life got in the way and I never finished it for the Pantera. But I ran a pair of adapted 40IDA 3-C Webers on my street Corvair for a decade, and they needed a choke not just for starting but until the thing was thoroughly warmed up. Or I got occasional bucking and popping. That was also the case with 40TIN Zenith 3-bbl weber-lookalikes.

My experience, as well as several San Jose Porsche owners with downdraft Webers: if you run paper or especially foam air cleaners and get a stack fire, the long aux venturis are cast pot metal and will instantly MELT. The molten metal then gets sucked down the intake and past any open intake valves into the combustion chamber. Then it solidifies.

On the next stroke, the pot-metal lump get pinched between the bottom of the piston & the squish area in the head, and cracks the piston, also breaking the top ring & maybe scoring that cylinder. So I had to overhaul the engine because of a backfire. IMHO, K & N oiled fiber air filters are not as good as paper at cleaning the air, but they don't soak up reversion gas either. That's what the Nor Cal air cooled Porsche guys use.

Like you, I found in the '70s there was no such thing as a specialty carb place. Most were racing teams or an occasional dyno shop. Good carbs, adjustable-everything but parts were/are expensive. Five jets, two air bleeds, a replaceable main venturi and replaceable emulsion tube- FOR EACH CYLINDER! Easy to get lost in the possibilities. Today I would be good friends with Jim Inglese and a local dyno shop instead of DIY.

FYIW, Weber started making 8-stack EFI systems when they stopped making carbs. I saw one set running on a Swiss Longchamp at one of the factory reunions in Italy. Don't know anything about them, though except they exist. I'll bet Roland in Germany does, though.

I got out of Corvairs in 71. The simplest would be to use the 140 two carb heads but it was nothing to send a kid up in a crate like that.

Jim is a funny guy. It's always a love hate relationship with him and I outgrew needing him thirty years ago. He's more of a bling guy and needs everything chromed.

Tom. A third transition hole is a very simple thing to do. Why they were never installed from the beginning is really a mystery to me. I want to be fair to all involved and say that 48ida's on a 289 Ford was an experiment from the beginning and the advantage for me of following all the seemingly haphazard developments through racing helped me get a perspective on the "necessity is the mother of invention" thing and not to be affraid to have my own designs even if they fail miserably and make me look like a fool. The other side to that is some of the simplest things make you look like an understating genius. It all goes with the territory.

The fact of the matter is most folks will never have the fogiest idea WTF you are talking about anyway and you have to be willing to use (steal) someone else's ideas and not be afraid of the "not invented here syndrome".

The solution to all the issues of an IR manifold with carburetors is to go to an EFI system. The current "Holley Eight Stack" is a Weber counterfeit with hidden fuel injectors within. FI is not subject to fuel reversion since there is no fuel held in suspension in the throttle bodies throats like in a carb. So there is nothing for it to blow out.

The problem with that system is it is at least $8,000 on your manifold. I would want to put two equally built Clevelands on a dyno. One with the carbs. The other with the EFI and compare them rpm per rpm. I've got a sneaking suspicion that the carbs are more responsive and make more power up top?

I already know the EFI is cleaner at idle. No comparison there.

Tom. When I bought my Weber manifold from Hall in '76 or '77, the "thin" part was exactly the discussion I had with Gary about the Detomaso part.

I actually talked to Kleipeter about buying his car around then. Gary laughed and told me stay away from it and buy a real Pantera. Kleinpeter reminded me of the "Mad Hatter" in "Alice in Wonderland".

Truths are truths. Some times haunting in retrospect and sometimes come back and haunt you?

Boss: Inglese had the DCOE sidedrafts working on his 66 GT350. They were on the car when he blew up the engine at about 8,500 rpm's in front of the ice cream shop in New Jersey at the SAAC 10 Convention at the former Playboy club. I never saw him run those again. You can't get the valve covers off unless you take the carbs off.

I'm still happy with this type of a delusion. It keeps me away from what looks like a mass delusion going on in some circles these days.

It's interesting to hear from you about your approach to things. I'm a do-it yourselfer and my Pantera has only been touched once by a professional engine builder. There is nothing on that car that hasn't been replaced or rebuilt over the years. I considered adding the third progression hole myself, with the help of U-Tube videos and advice from people like you it would have been easy. However on of the carbs had a worn bearing so one of the shafts would vibrate ever so slightly and activate the accelerator pump, dumping a bit of unneeded fuel down that tube. I could not loosen the screws on the butterfly valves without stripping them, so I decided to go new. I tried, i really did. Now I have four Webers sitting in a box and will probably still be there when I die.

My son is waiting to take over that car.

I wonder, how many Pantera owners are original owners?

@tomkuester posted:It's interesting to hear from you about your approach to things. I'm a do-it yourselfer and my Pantera has only been touched once by a professional engine builder. There is nothing on that car that hasn't been replaced or rebuilt over the years. I considered adding the third progression hole myself, with the help of U-Tube videos and advice from people like you it would have been easy. However on of the carbs had a worn bearing so one of the shafts would vibrate ever so slightly and activate the accelerator pump, dumping a bit of unneeded fuel down that tube. I could not loosen the screws on the butterfly valves without stripping them, so I decided to go new. I tried, i really did. Now I have four Webers sitting in a box and will probably still be there when I die.

My son is waiting to take over that car.

I wonder, how many Pantera owners are original owners?

You don't need to take the throttle plate off to change the bearings. They are under the throttle lever or the flat washer on the opposite side.

What you need to watch out for on IDA's is twisted throttle shafts. They are chromed brass and twist easily. That is usually a result of too much spring tension put on them by the throttle setup. They really don't need a lot of spring pressure to work right but some folks don't understand how to center the throttles and wind up with carbs that don't close all the way at idle after driving the car. So they think the solution is to put more spring pressure on the carbs?

The more you learn about the IDA's the more you respect the genius that went into them. They are incredibly simple and straight forward and totally un-Holley like. Gorillas need not apply. Maybe a ballerina would be a good match though?

Yes, they are marvelous carbs and could not look better than on a Pantera, peaking out slightly. After 40 years of being in the same location, the bearings would not budge. I was hesitant to be more aggressive even after many Blaster applications, so I was hoping to hammer them out from the inside. As it is, the day may come when somebody wants to buy them. They look perfectly new but need an expert touch.

Doug, I'm sorry you aren't closer to Carson City, NV- we have some mutual interests. Yes- I did start with Corvair big-valve 140s and sawed the log intakes off. Then welded stubs on to accept Webers. Also pulled the exhaust tubes and slant-bored new holes for curved tubes without the notch in them for pushrod clearance. I built maybe 6 or 7 pairs of these things for friends in the SF Bay Area. before the supply of Weber 3-bbls dried up. We autocrossed and a few ran them at Sears Point raceway with some success.

Then I bought the Pantera for my wife and we both started autocrossing that against Corvettes,Tigers and Lotus Europas. Good times.

@bosswrench posted:Doug, I'm sorry you aren't closer to Carson City, NV- we have some mutual interests. Yes- I did start with Corvair big-valve 140s and sawed the log intakes off. Then welded stubs on to accept Webers. Also pulled the exhaust tubes and slant-bored new holes for curved tubes without the notch in them for pushrod clearance. I built maybe 6 or 7 pairs of these things for friends in the SF Bay Area. before the supply of Weber 3-bbls dried up. We autocrossed and a few ran them at Sears Point raceway with some success.

Then I bought the Pantera for my wife and we both started autocrossing that against Corvettes,Tigers and Lotus Europas. Good times.

I saw the Weber modification as just a bolt on to the stock intake log. I had headers on mine. I thought it just lacked cubic inches and was thinking about a Corveight conversion.

I had a pair of Offe intake manifolds that you had to weld on. I never got up to welding aluminum well. I just sold those things a couple of years ago on ebay.

"Great minds think alike?"

It might cause a great risk of danger to the general public if you and I were closer together. Kind of like the "key master and the gate keeper" in Ghostbusters. You have to keep them separated. ![]()

Tom I think those bearings have two holes in the cover plates on them to use a puller on?

As far as Autocross goes, I tried it one year. Probably '75 or '76. At the time shopping centers were still closed here on Sundays and the "club" would "rent" the parking lots of some in remote areas.

The cars that would do well were Porsches and Lotus and other go-cart like vehicles.

You had to get there early on Sunday morning and walk the course where they had laid it out with chalk and plastic cones.

By the time my turn would come, the chalk was gone and I could NEVER follow the course and was ALWAYS a DNF.

They were always 8,000 rpm first and second gear screamers and I lost interest in getting beat up and beating up the car.

At some point, "facilities" just disappeared.

I can understand why drag racing is so popular. It's kind of like a bobsled run and you just have to keep from hitting the walls to get good times.

The only place left where you can LEGALLY go fast is at high speed events at race tracks like Pocono or Lime Rock. There are no drag strips left. Even English Town in NJ is gone.

NYS is getting smart now. They are installing video cameras along EVERY "Parkway". They realized that they do not have the manpower to patrol as necessary any more. Even I get pissed at getting passed by "bikes" going flat out in top gear at 14 or 15,000 rpm. Makes me feel like I got stuck in a revolving door. And they are like jet fighter planes in that you can't hear them coming until they zoom you.

Of course, just because the high speed track events were a lot of fun, the lawyers had to get involved in it and ruin it for all. The Trial Lawyers Association is very powerful here. They aren't happy unless everyone is miserable and need to hire an attorney to explain the track waiver form for them an notarize it.

Ian Flemming saw that coming decades ago when he renamed the Trial Lawyers Association, Specter. Even the Russians followed the pattern with Smersh.

This has been a great thread, but now I think that I now am starting to know how much I don't know. Allot actually. Most of it.

If you get me.

I have shut up until now as I previously had blissful ignorance and blind optimism firmly on my side and was forging ahead without the burden of any knowledge of any type. As is my preferred approach to life...!

Confession time - this is how far I am down the IDE road . Please don't laugh. Or if you must, please leave the room.

48ida's are blinkin hard to find here. ( Au) ((Had to steal these four off a Porsche parked at the local pub. Still got the gravel rash from when he took off. ))

Holman Moody built DeTomaso Weber manifolds or similar multi manifolds - forget it. Have not been able to find one. Be careful where you park.

Solution to reversion was to graft a cluster of these guys onto a Strip dominator manifold. - heaps of room in there for the vapor to sort itself out ,,,,,reversion , what reversion???

What could possibly go wrong ?

Here is the rough in on throttle linkage. Adaptor is definitely a work in progress.

The entire assembly is very high. Measures in at 270mm from the intake valley base without trumpets. May have to cut a hole in the roof to fit it. Not.

( And yes - I have previously worked on Massy Ferguson tractors....! )

Now if this ever sees use in anger may well depend on the fear factor instilled from Bosswrench's molten carburetor stories!!

I am almost scared to press the post reply button....

Attachments

Percy. Thanks for posting. Don't be afraid. No one here bites.![]()

Those IDF's likely will bring some bucks here in the US if you choose to separate yourself from them. They are from an era before the use of personal computers so it is unlikely that any states DMV's would have a cross reference to the Porsche that they were stolen from now.

There are lots of "custom" intake manifolds made to mount multiple Italian carburetors still in existence here. They are almost entirely made for custom street rods, heavily chromed and largely trailered around from show to show.

Some need winches on the trailers to pull them on and off since most won't even idle the engine.

I'm not sure which came first, the chicken or the egg? The point of using IDA's on V8 engines is a plan to use independent runner manifolds. I'm not sure if the concept understood that reversion was going to be an issue, that the extent of the issue was not known or if it was thought that it could just be managed to the point of non-existence initially?

Certainly the existence of the Boss 302 dual Holley Dominator manifold suggests that there was a thought that reversion was not going to be any kind of an issue on a race car? In reality, that was/is just not so. The inside of the Boss's hood gets soaked with atomized fuel and there have been attempts to channel that fuel to a location in the engine compartment where it would not be a fire hazard.

IF you start to look at intake manifold designs that were built and heavily used on '60s race cars, you will start to see that there was thought put to how can you have IR manifold benefits and retain a common plenum at the same time.

Certainly my C60A dual four Holley manifold CLEARLY shows that hybrid design characteristics.

The point of the IDA's was simply that they were small, compact and lend themselves well enough to an intake manifold design that would permit each cylinder to have it's own individual carburetor and that their throttles could be located at the optimum length to the intake valve. Thought to be right around 4.5".

So to the non-induction engineering inclined folks it absolutely looks like you can create any kind of an Alien device and IT WILL WORK! I think that saying in this case, "a little knowledge is dangerous" is more then appropriate?

My original air cleaner post exposed a lot of interesting information and the fact that we are having fun with this old technology. I wonder if our grandchildren will tinker with the new technology. Maybe some can, but it's totally over my head.

Recently one of my friends bought a new Ferrari Roma. The day after taking delivery we insisted that he bring it over for us all to see. Naturally we wanted to see the engine. After a few minutes he conceded that he didn't know how to pop the hood. He didn't have the manual with him.

My original post asked about running Webers without air cleaners. Inversion etc. came into the discussion.

So.....how much damage can I cause the motor by not using any air cleaner? Weber air cleaners look terrible. I've been doing it on and off for years, sometimes I run a 4brl Holly to clean the carbs. It runs perfect and blows no smoke. The motor was rebuilt for less HP to make it less angry about 5000 miles ago. Now it has 27000 total miles on it.

It's interesting how different the motor sounds when using the Holly. The motor has a mild lope with Holly, but not with Webers.

Attachments

I still have a lot of work to do on the adaptor piece between the Weber's and the intake. If I had a super smart son, some super cool 3d printer could be printing one for me in metallic fiber.....!

Hang on ........ watch this space......!

Can we have a picture of the C60A dual four Holley manifold ?

Thanks!

Funny you should mention it, but my son works for 3D Systems that builds 3D printers of all sizes and abilities. Metal is easy, but very pricy.

Hey Tom , thanks . My son has a printer that could do it , I have been the problem in getting the basic layout sorted. The new tech is not the issue , its the old tech thinking driving it ! But it is the way to go on these difficult transition pieces.

Percy,

I'm impressed that your son has a printer capable of printing metal. All you need then is to build a computer model that can be printed. That's easy! not!

Look up evankuester.com for my son's work in 3D printing, metal and all. Maybe our sons have something in common.

Thanks Tom - will do. They must have got it from their mums....

What brilliant work your Son does - simply life changing .

Attachments

@Percy posted:I still have a lot of work to do on the adaptor piece between the Weber's and the intake. If I had a super smart son, some super cool 3d printer could be printing one for me in metallic fiber.....!

Hang on ........ watch this space......!

Go look at Jiminglese.com. He already has an adapter made for your set up.

The installed pic above of the C60A Trans Am intake ^ is on my 68GT350. It is the original 68 302 block stroked to a 347.

This is the setup I'd do in a Mangusta.

@Percy posted:This has been a great thread, but now I think that I now am starting to know how much I don't know. Allot actually. Most of it.

If you get me.

I have shut up until now as I previously had blissful ignorance and blind optimism firmly on my side and was forging ahead without the burden of any knowledge of any type. As is my preferred approach to life...!

Confession time - this is how far I am down the IDE road . Please don't laugh. Or if you must, please leave the room.

48ida's are blinkin hard to find here. ( Au) ((Had to steal these four off a Porsche parked at the local pub. Still got the gravel rash from when he took off. ))

Holman Moody built DeTomaso Weber manifolds or similar multi manifolds - forget it. Have not been able to find one. Be careful where you park.

Solution to reversion was to graft a cluster of these guys onto a Strip dominator manifold. - heaps of room in there for the vapor to sort itself out ,,,,,reversion , what reversion???

What could possibly go wrong ?

Here is the rough in on throttle linkage. Adaptor is definitely a work in progress.

The entire assembly is very high. Measures in at 270mm from the intake valley base without trumpets. May have to cut a hole in the roof to fit it. Not.

( And yes - I have previously worked on Massy Ferguson tractors....! )

Now if this ever sees use in anger may well depend on the fear factor instilled from Bosswrench's molten carburetor stories!!

I am almost scared to press the post reply button....

The early "Webers" are serial numbered. The code 1/100 and 2/100 are the serial numbers on those carbs. Translated that means that those two are #1 and #2 of 100 made.

They should be in a museum. I know someone who MIGHT know what they may have originally be intended for and will ask.

A couple more variants-

There used to be a popular right-angle adapter that mounted two 48 DCOE side-draft Webers on a 351-C 4bbl intake. No engine screen interference and easier tune than a 4-carb stack intake. Any reversion drips on the rocker covers, I suppose. The CA car I'm thinking of had outstanding drivability. Owner now passed away & the car disappeared 15 yrs ago.

An owner in OH has a 48 IDA Weber stack setup that features "dried-up" Webers with hidden EFI. To dry up Webers, you remove the venturis, aux venturis and block off all fuel feeds with fake braided stainless lines. The Webers then become very expensive throttle bodies, but the owner wanted the classic look and can afford it. Haven't heard how it runs.

Thanks Guys - that is great information. As for the throttle bodies belonging in a museum, I think it well matches the owner! Now if I can only find numbers 3 and 4....!? Good luck with that.

Panteradoug - I would be interested if there was any information on the original use. I fibbed about the Pub and Porsche. That was for CV joints....!

These things have been gathering dust for the last thirty years and I could imagine someone seeking the restoration of an historically perfect classic may well value them if they matched the original build specification of their vehicle.

Bosswrench _ I am going to start looking for a right-angle adapter to mount the two 48 DCOE side-draft Webers on a 351-C 4bbl intake. As soon as I read that I thought it would be a possible way forward. Brilliant.

Tony ( Edge ) was very kind and generously showed me the EFI setup on his extreme Pantera yesterday . It was similar in form to the Borela arrangement but had external injection ports on the carburetors. The fuel management he has built system is quite complex and the EFI system was more than a bit intimidating for a newby like me. He is building a ultra lightweight 427 dart block to go into it , so still a major work in progress. I certainly was in awe of what he has done and now have some appreciation of the complexities of a first class EFI install, and what it would entail.

I cannot thank him enough for his hospitality and sharing his knowledge.

You're very welcome, Percy. and good luck with your search. Note that an open-plenum type 4bbl intake will work best for the DOHC Weber adapter, I think.

Yup. They look just like them. Very pricey though. That seems to be coming around again for me David? I feel a project coming on. I've got to go looking at CPU combinations. I don't like the manifold that Borla is offering for their set up as the linkage requirement on a Pantera is unique which is why the cast in linkage tower is on the Hall and Detomoso manifolds.

You need to mount the carbs/throttle bodies with the fuel inlets outboard so that you have reasonable throttle access running down the middle of the manifold.

On a Pantera it is hard enough to work on them to begin with and changing the access to the linkage could be the straw that breaks the camels back?

The original design considerations for the mounting on the Pantera are correct for the car but if you mount them on a different car like for instance a Mustang you want to reverse the entire linkage design and run the carbs in parallel and side mount the throttle. That is where sometimes the "experts" disagree.

I've run them both ways on both cars and perhaps the criticism against my advice is that others don't understand that I have a unique perspective on that subject?

You might find my next comment moot but I have found that there is a loss of power across the rpm scale if you mount the carbs in parallel. The reason is that you change the line of sight from the throttle plate opening to the valve.

Seems silly but the power change is very measurable.

There were several vendors that had the adapters for the side drafts listed. Hall had pictures of them installed on a Pantera. Probably the car that you are thinking of Boss?

You need to note though, that the point of the down drafts was that you were able to achieve the optimum distance to valve of 4.5 inches and direct line of sight to the intake valve. You can't do that with adapters or with the side drafts.

You can do that if you take the FI side draft intake manifold and rifle bore the throttles thorough the manifold mounting flanges. To this day I have not seen anyone do that.

I am not versed on the IDF's. The Cobra guys aren't either so I'd have to search for that chapter of expertise and am wondering if those "authors" are still with us?

I do know that they were on the earliest factory Cobra race cars with 260's. That's like one or two cars. Where they were "sourced from" I don't remember and I'd be relying on the accuracy of early magazine articles and hope that the author mentioned that and that I've just forgotten?

There is a lot of mis-information on this thread. The first large downdraft Weber carb was the 45 IDM (M=Maserati) developed for the 1957 Maserati 450S race cars. These carbs were also used on very early competition Cobras. Then came the 48 IDA (A=Abarth) which were a modification of the IDM and slightly larger bore. This is the common downdraft Weber of the Cobra era. For a number of years, Weber stopped production, but now they are making them again in Spain. Most versions of this carb have only two progression holes and are a little "tricky" to make run smoothly on the street. We always add a third progression hole even with vintage race engines. I am not sure, but the current production IDA's may have three holes. The 48 mm bore limits the effective use of this carb to about 350 cu. in. engines. These carbs can be bored to 50 mm to help a little on larger engines. Ford financed a very limited series of 58 IDA units for the 255 Indy engine of 1962. They also appeared on some larger displacement Can-Am engines. Next comes the 40 and 48 IDF (F=Fiat) units. These are far more sophisticated carbs as they were designed for street use from the start. They have three progression holes and diaphragm accelerator pumps instead of the old piston pumps of the IDM/IDA series. They are easily tunable for street use and are less expensive than the IDA series. The downside of this carb for race usage is it has poorer interior streamlining than the IDA and therefore does not flow as much air at full throttle. Ford specified 48 IDA's with 37 mm venturis for street applications and 42 mm venturis for race usage in the day. Today, we bore the venturis to 45 mm for a modern vintage race motor. We use 38-40 mm venturis on 289 street engines. IDF's can easily use 40 mm venturis on street 302-351cu. in. engines.

I will review the details on the manifold but I think that is one that has cast in a vacuum plenum?

Even if finances permit, I don't want to switch manifolds, just replace carbs with EFI to clean up the idle.

The 4v intakes and A3 intake ports don't line up. I haven't seen a "high port" IR manifold other then the Hall that I am using.

Modifying a 4v means closing up the bottom of the port 5/8" and raising the top 1/4". That makes either welding or epoxy filler necessary.

The original Weber look-a-like throttle bodies were a Dynatec design. Those throttle bodies in particular have had machining accuracy issues which created idling issues with them. Supposedly Borla corrected that when they bought out the line?

I have a quote here from Dynatec for $2,800 for four. Borla doubled the price.

What CPU to use with them now seems to be the big issue. Apparently the self learning CPU's are blamed for erratic running conditions. That's another issue to be dealt with. We'll see.

Doug, it would be pointless for you to buy a new manifold. In fact, in my opinion, you’re better off with the one you have. That Borla manifold has a large vacuum plenum. You really only need a plenum that large if you have a MAP sensor and an IAC sharing the plenum. I don’t have an IAC so I have a very small MAP plenum. With your manifold, you can choose the size of plenum you use, as well as choose where you want to put it.

@davidnunn posted:Doug, it would be pointless for you to buy a new manifold. In fact, in my opinion, you’re better off with the one you have. That Borla manifold has a large vacuum plenum. You really only need a plenum that large if you have a MAP sensor and an IAC sharing the plenum. I don’t have an IAC so I have a very small MAP plenum. With your manifold, you can choose the size of plenum you use, as well as choose where you want to put it.

Thank you for that info David. I already have an oxygen sensor installed (for an A/F ratio gauge) and a vacuum manifold installed for the vacuum gauge.

The linkage stays the same and I can reuse my stacks and screens. So I need the throttle bodies and cpu.

Which CPU to use is the most controversial and item of disagreement.

There was some discussion on the Holley CPU since Borla is part of the "Holley Family" now.

Doug, I can only tell you what my experience has been. I have a Holley Dominator ECU. I went with the Dominator because I wanted to use dual O2 sensors without an add-on module and I wanted the capability of blending both types of EFI logic; speed density and Alpha-N. I also wanted flexibility in what I used to generate the cam sync. and crank signals. I didn't really care whether Holley's tech support was any good but I wanted to buy an ECU that was manufactured by a substantial company, that was likely to still be in business in ten years. That being said, the proof is in the pudding and I'm happy to report that my EFI system works better than I ever expected it to.

I've attached a video taken out of the rear window of my Pantera. Turn your volume up! Notice how little throttle it takes to get the car moving along. Also notice how smooth the idle is. I have a solid roller cam and you can roll a golf ball through my mufflers but you'd never know it because EFI smooths the motor completely. I'm not sure everyone would think that's a good thing but I do!

Attachments

Yes but without being my own dyno shop I have to review all comments of people who have done or attempted to do this regardless of whether or not they actually understand or know what they are doing.

You for instance are using different throttle bodies. There have been comments that I must presume have significance that the Borla Weber look-a-likes have a different fuel injector location above the throttles plates then another Borla design which injects under the throttle plates and as such the CPU program APPEARS inadequate to deal with the differences.

One comment was that with the Borla Weber look-a-likes, the Accell CPU was the solution. So at the moment I need to look for specific comparisons to what I want the finished product to be? I can't spend my life looking for a solution.

At this moment I would anticipate ONLY a CPU that controls the fuel delivery system and not the ignition, leaving the ignition alone and as is.

Interestingly enough is that there is no comment on the Jenvey's at all?

It is ENTIRELY possible that those who have said, "the car 'runs great' ", haven't got the foggiest idea what they are talking about, are looking at or experiencing? On the other hand, it probably is also likely that there is not or never will be a complete 100% solution? For me, I could also go back to an imperfect carburetor solution as a fall back.

Certainly it is common place for racers to swipe at each other and treat the opposition as if they are a bunch of retarded no nothing individuals. That is a concern with competing "tuners" that I have as well.

Even so, I am not convinced that the "expert tuners" are actually able to or have done a side by side comparison of both throttle body types and CPU systems to compare the best combinations. I think in all fairness, that would be a very difficult if not impossible task.

They certainly are experts on some of the CPU systems and therefore have their ideal selections that they have been able to tune in their eyes successfully. No one here has the capability of NASA.

For me, so far Borla's and Jenvey's are on the map. I have not discovered other Weber look-a-likes. The Jenvey's appear to be more reasonably priced as well at $719 each v $1,200 each fo the Borlas.

Doug, don’t get too caught up in discussions about one ECU or another. Once you find a CPU that has the features and inputs/outputs that you want, a successful installation simply depends on your ability to navigate the software. All the ECU does is tell the injectors when to squirt fuel and for how long. If someone tells you they solved a tuning issue by changing ECU’s, it simply tells you that they couldn’t navigate the software that controlled the previous ECU. Pro tuners rarely have such issues.

I'm talking with Pantera Electronics about the compatability of the P-E Ignition Controller and what is necessary to adapt it to a CPU.

It may simply be that it needs a module to communicate with the CPU to tell it when the ignition is firing.

The question is if one already exists as a plug in or I need to search the Universe for one. At the moment it doen't sound like there is one or if the original designer ever had that as a consideration.

Progress is slow but it is progressing in the right direction. A plug in would be the simplest but why make things simple?

I'm told that on the CPU part all that is needed is a "trigger" port.

I'll agree with you in that every thing new initially seems to be a steep learning curve. I've recently felt my brain growing sideways. That's ok. I still have lots of hair to cover the head profile distortions it creates. I was always ugly anyway so not many notice it.

Does the PE Ignition controller have a tach output? That might be all you need for a simple batch fire EFI system. If you want to go sequential, you’ll need a cam sync signal and a crank signal.

I don't know. It's been in there for quite a while and typically with Jon's products, once you install them, you never have to look at them again. EVER.

That's usually a good thing but when you need to remember the details, you need to call on Indiana Jones to do some archeological investigations. Then you run into Nazi's. I hate Nazi's.

I have the early case design P-E-IC. I didn't like the MSD case design of the newer ones. I didn't ever want to be associated with MSD again in any way, form or even shape. Once bitten twice shy. Three times bitten then you need a pre-frontal lobotomy. Did I just admit that?

@davidnunn posted:Does the PE Ignition controller have a tach output? That might be all you need for a simple batch fire EFI system. If you want to go sequential, you’ll need a cam sync signal and a crank signal.

Jon reports that the tach output wire is TACH ONLY. My early IC needs to have a dedicated trigger wire added to it.

In sorting through the available CPU's the information is as cumbersome and confusing as ever.

That is simply going to take some time to filter out the spam.

This isn't as complicated as it first seems. It is falling into place fairly easily. Much of the internet info is old news that no longer seems to apply.

Some options if you just want two side-draft webers to replace a 4-bbl Holley.

https://www.lynxauto.com.au/tw...ld-adaptor-lynx.html

https://www.carbparts.eu/Manifolds?cat=3292540319

Chinese knockoff: https://www.aliexpress.com/item/1005001665659868.html

https://www.weberperformance.c....php?products_id=119

Thanks, Garth. The photo second from the bottom is what the car "Edible Red" had on a medium-height tunnel-ram intake, with a flat-tappet cam. Still can't remember the deceased owners' name, but I can 'see' it's candy-red paint in my mind- hence the car's name.

the big block chevy image makes my 351c with Webers look downright anemic, but it still goes pretty well

Attachments

Edible red was owned by Howard Bourquin.

@davidnunn posted:

I agree but it is up to the moderator to split it.

Tom- elegant I think is the word you were looking for ....!

Garth- do you have any pictures of the throttle linkage set up required for the two side-draft webers arrangement when replacing a 4-bbl Holley?

I am having trouble seeing how it could be laid out.

@Percy posted:Garth- do you have any pictures of the throttle linkage set up required for the two side-draft webers arrangement when replacing a 4-bbl Holley?

I am having trouble seeing how it could be laid out.

Unfortunately I do not. I only found those online but have not seen one installed in-person. Some more Google searching may yield a result.

Thanks - I will keep looking.

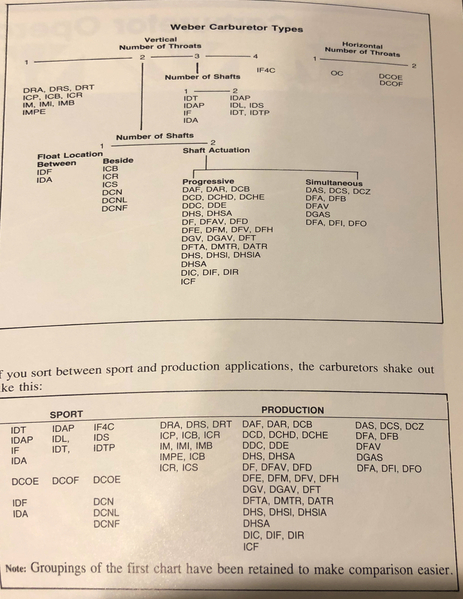

Found a great chart in a 1988 publication "Weber Carburetors" by Pat Braden.

He sorts the Weber family by the number of throats and shafts , float position and the style of actuation. I have not found anything similar to describe the groups of Webers in my searches. He attributes the IDFs to either Ferrari or Ford application , which is interesting. Just thought I would share this for interest.