Maximum power: 108,920 hp at 102 rpm

Maximum torque: 5,608,312 lb/ft at 102rpm

The Wartsila-Sulzer RTA96-C turbocharged two-stroke diesel engine is the most powerful and most efficient prime-mover in the world today. The Aioi Works of Japan 's Diesel United, Ltd built the first engines and is where some of these pictures were taken. It is available in 6 through 14 cylinder versions, all are inline engines. These engines were designed primarily for very large container ships. Ship owners like a single engine/single propeller design and the new generation of larger container ships needed a bigger engine to propel them. The cylinder bore is just under 38" and the stroke is just over 98". Each cylinder displaces 111,143 cubic inches (1820 liters) and produces 7780 horsepower. Total displacement comes out to 1,556,002 cubic inches (25,480 liters) for the fourteen cylinder version.

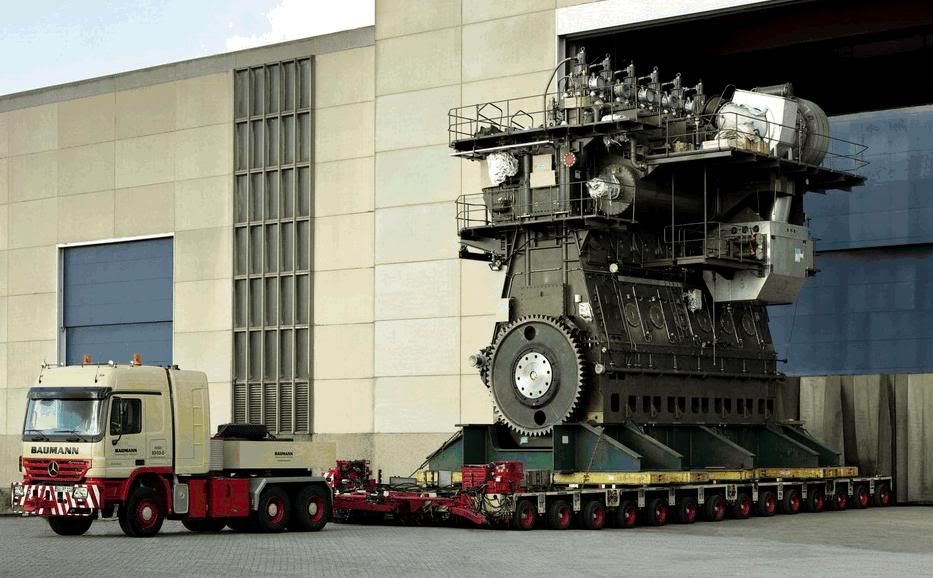

Some facts on the 14 cylinder version:

Crankshaft weight: 300 tons

Total weight: 2300 tons

Length: 89 feet

Height: 44 feet

Maximum power: 108,920 hp at 102 rpm

Maximum torque: 5,608,312 lb/ft at 102rpm

Fuel consumption at maximum power is 0.278 lbs per hp per hour (Brake Specific Fuel Consumption). Fuel consumption at maximum economy is 0.260 lbs/hp/hour. At maximum economy the engine exceeds 50% thermal efficiency. That is, more than 50% of the energy in the fuel in converted to motion. For comparison, most automotive and small aircraft engines have BSFC figures in the 0.40-0.60 lbs/hp/hr range and 25-30% thermal efficiency range. Even at its most efficient power setting, the big 14 consumes 1,660 gallons of heavy fuel oil per hour.

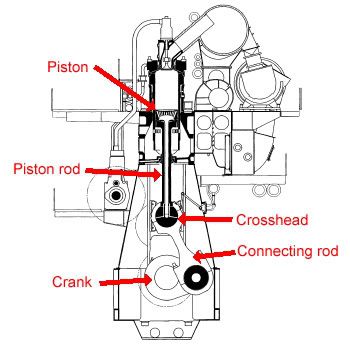

A cross section of the RTA96C:

This engine employs a piston rod between the piston and the connecting rod; the top of the connecting rod is not attached directly to the piston, it attaches to a "crosshead" which rides in guide channels. The long piston rod then connects the crosshead to the piston. Side forces are absorbed by the crosshead and the guides, the only forces applied to the piston are upwards and downwards.

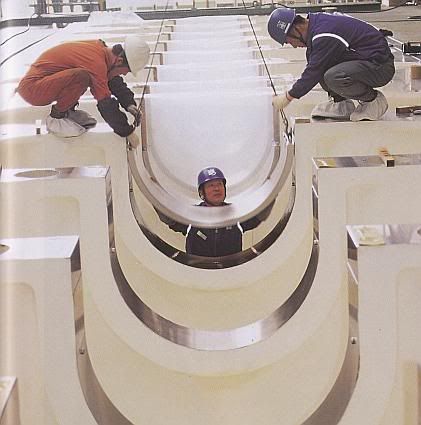

Installing the "thin-shell" bearings. Crank & rod journals are 38" in diameter and 16" wide

The crank sitting in the block (also known as a "gondola-style" bedplate). This is a 10 cylinder version. Note the ladder rungs by each crank throw that lead down into the crankcase

A piston & piston rod assembly. The piston is at the top. The large square plate at the bottom is where the whole assembly attaches to the crosshead

Some pistons

And some piston rods

The "spikes" on the piston rods are hollow tubes that go into the holes you can see on the bottom of the pistons and inject oil into the inside of the piston for cooling.

The cylinder deck (10 cylinder version). Cylinder liners are die-cast ductile cast iron.

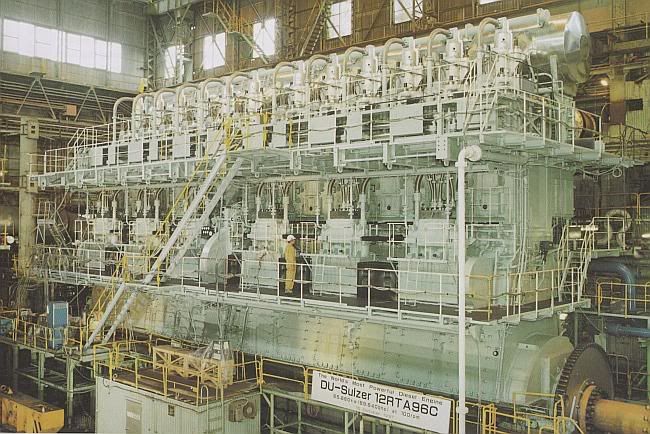

The first completed 12 cylinder engine