SteveD recently started a thread about an intake manifold swap in which we discussed how to bring the 351C 4V up to pre-smog specification. Ever since then I've had this bit of history running around inside my head.

I hope you enjoy & I humbly submit the following historic info:

Few people realize that the state of California established automotive tailpipe emissions standards in 1959, the first tailpipe emissions standards found anywhere in the United States. The U.S. Clean Air Act of 1963 was the first federal legislation regarding air pollution “control”. All further federal air pollution control legislation has been enacted via a series of minor amendments and two major amendments (1970 and 1990). One amendment, the Motor Vehicle Air Pollution Control Act of 1965 established the first federal automobile tail pipe emissions standards, which became effective as of model year 1968. The new national standards for 1968 were modeled after California’s standards for model year 1966.

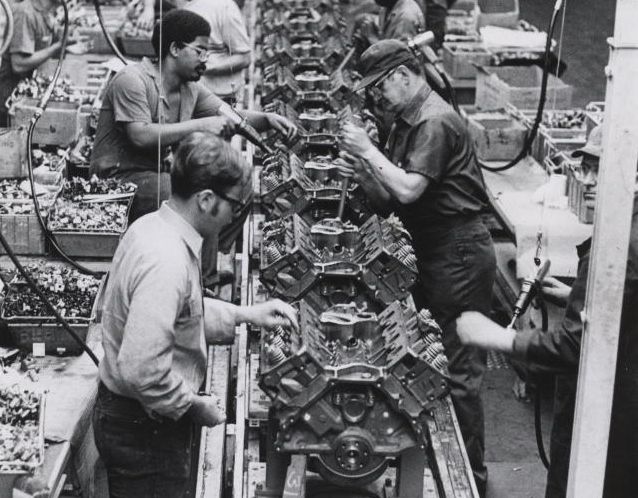

Model year 1968 was therefore a turning point for the thundering engines of the muscle car era. The tail pipe emission laws were written in such a way that they not only limited the percentage of pollutants in tail pipe emissions, they also limited the quantity of pollutants an engine was permitted to exhaust into the atmosphere over a given period of time, under prescribed test conditions. Limitations in the quantity of pollutants impacted high rpm performance engines and engines of larger displacement more than they impacted standard engines and engines of smaller displacement. High compression - high revving engines such as Ford’s dual quad 427 and high performance 289 were replaced in 1968 by a new breed of performance engine typified by the 428 Cobra Jet. As of 1968 camshafts had less duration and less overlap, compression ratios were lower, and carburetors were calibrated leaner. The amount of air pollution control equipment found on US automobile engines increased while the horsepower ratings generally decreased.

The concern for leaded gasoline’s effect upon public health was decades old even in the 1960s. Renewal of this concern lead to a movement in 1969 to eliminate lead in gasoline, and the auto corporations were supportive of the movement. Voluntarily lowering automotive engine compression ratios was a way for the auto corporations to support the movement since lead was used to boost gasoline octane. GM lead the way, model year 1970 was the last year for high compression engines at General Motors. Ford followed GM's example and eliminated high compression engines from their fleet before the end of model year 1971. If lead wasn’t utilized to boost gasoline octane, the prevailing belief was only low octane gasoline would be available. Engines equipped with 4 barrel carburetors were traditionally designed by the US automakers with higher compression ratios. Reducing the octane of gasoline obviously impacted high compression engines more so than low compression engines which were already designed for low octane gasoline.

Up until 1970 state and local governments had been primarily responsible for addressing the air quality issues identified by the Federal government. Implementation of air pollution reduction programs had been inconsistent from state to state and the enforcement of air pollution regulations had not been altogether effective. Testing revealed that more than half of the cars manufactured during model years 1968 and 1969 failed to meet the tailpipe emission standards set by the Federal government for those years. Improvements in air quality were not progressing at a pace acceptable to the public, lobbyists and politicians; therefore policymakers passed the Clean Air Act of 1970. Although technically an amendment to the original Clean Air Act of 1963, the Clean Air Act of 1970 was a complete make-over of the 1963 legislation and its subsequent amendments. It was very aggressive legislation which set more demanding standards that progressed at an accelerated pace. The Clean Air Act of 1970 also increased the role of the Federal government in implementing air pollution control programs and enforcing air pollution regulations. The Clean Air Act of 1970 was often referred to as the "Muskie Act" because Senator Edmund Muskie of Maine played a major role in drafting the bill.

The Muskie Act originally mandated that all states and regions of the United States had to attain clean air status by 1975, in terms of automobile tailpipe emission that meant most automobiles sold in the United States would be equipped with catalytic converters by 1975. Leaded gasoline poisons (i.e. renders ineffective) the catalyst in catalytic converters, so the use of catalytic converters became a secondary mandate for the elimination of lead in gasoline. The movement to eliminate lead in gasoline actually preceded the passage of the Muskie Act by more than a year however.

US Ford withdrew support from all racing in autumn 1970, "except for limited drag racing and off-road racing support on a divisional level and dealer level" to focus engineering resources (personnel, time and budget) on keeping up with government mandated safety regulations and tailpipe emissions regulations. To reduce tailpipe emissions to levels established by the new standards in the short period of time set forth by the Muskie Act placed unreasonable demands on the diminishing economic resources of the auto corporations and exceeded their technologic limitations. By mid-decade the government realized the deadlines set for auto tailpipe emissions were overly ambitious, and the emissions compliance deadlines set by the Muskie Act were extended.

I began this story summarizing the US tailpipe emission laws and the conversion to unleaded gasoline because Ford began manufacturing the 351C in August 1969, a few months after the beginning of model year 1970. It came on the scene as compression ratios were being lowered and lead was being removed from gasoline. The Muskie Act became law only months after the 351C went into production. Each year of its 5 year production history was impacted by the removal of lead from gasoline and the Muskie Act’s demanding standards and accelerated pace. It was an era of rapid and continual change for the auto industry. The performance goals Ford had for the 351C 4V were superseded by the need to adapt its engines to the use of un-leaded gasoline and to comply with the mandates of the Muskie Act. For reasons already explained the specification of the low compression 2 barrel carburetor version of the 351C remained basically unchanged throughout the 5 years it was manufactured in the US, but the 4 barrel carburetor equipped 351C was offered in 3 distinct versions in that same time period, and each version was subjected to annual changes.

For the readers not familiar with the terminology, the 351 Cleveland engines equipped with 4 barrel carburetors were manufactured in 3 versions we refer to using Ford's engine codes for those engines; i.e. the M-code engine, the Q-code engine, and the R-code engine. The 2 barrel carburetor version is referred to as the H-code engine for the same reason. In Ford terminology a 351C equipped with a 4 barrel carburetor was referred to as a 351-4V; 4V did not mean 4 valves as it does today, rather it meant the carburetor had 4 venturis. For the same reason a 351C equipped with a 2 barrel carburetor was referred to as a 351-2V. All 3 versions of the 351-4V were tuned for higher rpm with cylinder heads having raised intake ports of larger cross section than the heads found on the 351-2V. Those heads were known as 4V heads because they were designed for engines equipped with four barrel carburetors. The 4V heads were also initially equipped with larger 2.19" intake valves and 1.71" exhaust valves. The cylinder heads installed on 351-2V engines were referred to as 2V heads, they were equipped with 2.04” intake valves and 1.65” exhaust valves.

Engineers believed the lead contained in gasoline cushioned valves and valve seats as engines were operating, thus reducing valve and valve seat wear. Ford engineers decided to apply an aluminized coating to the valve faces to cushion the valves and valve seats in place of the cushioning that had been provided by lead. The 351 Cleveland valves were of two piece construction wherein the heads are joined to the stems by a friction welding process. This should not be considered inferior or unusual; it is standard practice to manufacture automotive valves this way. The 351 Cleveland valves were manufactured to the same standards of quality and durability Ford valves had always been manufactured. However as a final step in the manufacturing process the aluminized coating was applied to the valves by heating up the heads and spraying liquid aluminum on the valve faces. When this was done it crystalized the metal in the heads which made them brittle and therefore more prone to breaking. The factory OEM 351 Cleveland valves (both 2V and 4V) have a history of the heads developing cracks and breaking off the stems while the motor is running; not because the valves were of two piece construction, but because the heads were brittle.

In model year 1970 the M-engine code designated a 351 cubic inch 4V motor with a low-lift hydraulic tappet camshaft and a small 630 cfm 4 barrel carburetor. It was the lowest priced, entry level performance engine. The first couple of months of production the 351-4V was actually a 351W, the 351 V8 manufactured in Windsor Canada. The 351C, manufactured at Cleveland Engine Plant number 2, was a little delayed going into production. The Q-engine code in 1970 designated the 428 Cobra Jet. And the R-engine code designated the solid tappet 428 Super Cobra Jet. The 351-4V was equipped with 4V cylinder heads having quench style combustion chambers and was rated at 11:1 compression, which would have required super premium fuel, a commodity which was on its way out. So while Ford did not revise the rating on paper, the 351C-4V went into production with an actual compression ratio of 9.95:1. The output was rated at 300 SAE "gross" horsepower.

The 1971 engine manuals list both the M-engine code (351-4V) and the Q-engine code (351-4V-GT) in the engine code data section. This indicates the Q-code engine was planned from the beginning of the model year. However, although the Q-code designation had been assigned to the new 351-4V-GT, the engine manual contained no details about the engine. This indicates the Q-code engine's specification had not been determined at the time the engine manuals were printed. Whether or not it was planned to happen this way I don't know, but the Q-code engine was not made available until May 1971. From the point of view of vehicle production data I am satisfied to say that rather than wait for 1972 to introduce the new 351 Cobra Jet it was "phased-in" at the end of the 1971 model year.

What happened is this. The 351-4V-GT was delayed going into production. No doubt the new mid-size performance engine was originally intended to be a high compression engine, but Ford had to scramble and revise the engine's specification for lower compression and lower tail pipe emissions. So the M-code engine was offered at the beginning of the 1971 model year as a low-priced, entry level performance engine. Its specification was similar to its 1970 specification; it was equipped with a small 630 cfm 4 barrel carburetor and rated at 285 SAE "gross" horsepower. The advertised compression ratio was lowered to 10.7:1 although the actual compression ratio was 9.59:1; this was accomplished by increasing the volumes of the 4V cylinder head quench style combustion chambers by 3.3cc per cylinder. If you wanted the top performance motor in your Ford or Mercury at the beginning of model year 1971 you purchased the C-code engine, which got you the 429 Cobra Jet rated at 370 SAE "gross" horsepower. There was also a J-code solid tappet 429 cubic inch motor option, i.e. the 429 Super Cobra Jet, rated at 375 SAE "gross" horsepower.

The big changes occurred about May 1971, almost the end of the 1971 model year. The C-code and J-code engines, which were high compression engines, were both "phased-out" of production, as the new low compression (rated at 9.0:1) Q-code 351-4V-GT, i.e. the 351 Cobra Jet, was “phased-in”. The 351 Cobra Jet was rated at 280 SAE "gross" horsepower, it was equipped with a high-lift hydraulic tappet camshaft, 4V cylinder heads having open style combustion chambers, and a 750 cfm Autolite carburetor. The 1971 Q-code engine was manufactured less than 2 months. It became Ford’s top performance motor aside from the 330 SAE "gross" horsepower R-code 351 HO engine (i.e. Boss 351) which was a limited production "homologation" engine.

The 1971 engine manual did not list an R-code engine in the engine code data section; it listed the G-code 302 HO engine (Boss 302). Ford was making the transition to low compression engines however, which meant model year 1971 was the last opportunity to homologate a high compression 351C racing engine. So the plans to use the 302 HO engine in the 1971 Boss Mustang were dropped, and Ford engineers quickly designed a 351 HO engine to replace it. The R-code engine was therefore a little late in being offered to the public (along with the Boss 351 Mustang); it appears to have been manufactured in low numbers between November 1970 and July 1971. The timeliness of this decision made it possible for Bud Moore to race the "Boss 351" in NASCAR beginning 1972. This also left Boss 302 enthusiasts with a good supply of service parts having 1971 casting codes. The R-code engine was equipped with a solid tappet camshaft, a 750 cfm Autolite carburetor, 4V cylinder heads having quench style combustion chambers, 8cc pop-up dome pistons and it was specified as having 11.1:1 compression, although the actual compression was about 10.63:1.

The Q-code and R-code engine codes, which had been assigned to the pair of high performance 428 engines in 1970, were thus re-assigned to the 351 engines in 1971. Ford accomplished what it had been planning to do for at least half a decade; they replaced the 7 liter high performance motors with smaller mid-size V8 performance motors. The output of the 351 Cobra Jet must have been originally intended to be about 330 horsepower, which was close to the output rating of the 428 Cobra Jet, but the Muskie Act took its toll on the output of the 351 Cobra Jet.

1971 was the last year for high compression engines at Ford; they had in fact phased-out many of them before the end of the 1971 model year. There were no high compression engines in Ford's engine line-up in model year 1972. The last two months of the 1971 model year were also the only months in which all 3 versions of the 4 barrel carburetor equipped 351C were offered simultaneously. Although the M-code 351-4V could have occupied the middle ground between the high performance Q-code 351 Cobra Jet and the H-code 351-2V, no such engine was manufactured in 1972. The M-code designation was not assigned to any engine in model year 1972 or later.

For model year 1970 Ford had manufactured a total of 7 different performance engines as standard equipment or optional equipment for various models among its fleet of automobiles; for model year 1972 it manufactured only two … the 351 Cobra Jet and the 351 HO. The US automakers adopted specifying the output of their engines as SAE “Net” horsepower in model year 1972, thus the output of the 351 Cobra Jet was specified as 266 "Net" horsepower. The camshaft timing of the 351 Cobra Jet was retarded by four degrees, which lowered the "dynamic" compression ratio a small amount. The 1972 R-code 351 HO engine was not listed in the engine manual’s engine code data section for the second year in a row; and there was no 1972 Boss Mustang planned, the Boss Mustangs were a thing of the past. But engineers at Ford, determined to offer something better than the Q-code version of the 351C, found the time and budget to modify the R-code 351 HO for low compression & lower emissions. They equipped it with 4V cylinder heads having open style combustion chambers, flat top pistons and a solid tappet camshaft having shorter duration but higher valve lift. This revised 351 HO engine was made available late in the model year rated at 275 "Net" horsepower. It was manufactured in even more limited numbers than it had been in 1971; it was manufactured between January 1972 and about June 1972.

In model year 1973 Ford manufactured only one performance engine … the Q-code 351 engine. The compression ratio of the Q-code engine was lowered to 8:1 by increasing the volumes of the 4V cylinder head open style combustion chambers by 3cc per cylinder and adding 5.8cc dishes to the tops of the pistons (two valve notches plus a 5.8cc dish gave the 1973 piston tops a total volume of 8cc). It was equipped with exhaust gas recirculation, and smaller 2V size valves were installed in the large port 4V cylinder heads to restore the low rpm power lost when the compression ratio was reduced. The engine was rated at 246 "Net" horsepower which was the highest output engine offered by Ford outside of the big 460 V8 offered for the "biggest and heaviest Fords". The output of the 460 V8 was rated about 268 horsepower in that model year. There was no R-code 351 HO engine manufactured in 1973.

Model year 1974 was the last year the 351C was manufactured in the US, the Q-code engine's specification was unchanged from 1973 but the output rating rose to 255 horsepower. Ford never manufactured the 351C in a version that realized the engine’s full potential due to the tail pipe emission regulations which impacted the engine’s specification year by year since its introduction. The 351C did acquit itself admirably however when it is compared to other engines manufactured in the same era. Here’s the outputs of the competition’s top V8’s for 1974:

• Pontiac Trans Am Firebird (Super Duty) 455 cubic inch V8 – 290 horsepower (limited production)

• Chevrolet Corvette (LS4) 454 cubic inch V8 – 275 horsepower (limited production)

• Chrysler (Magnum) 440 cubic inch V8 – 275 horsepower (limited production)

• American Motors 401 cubic inch V8 – 255 horsepower

• Buick 455 cubic inch V8 – 255 horsepower

• Ford 351 cubic inch V8 – 255 horsepower

• Chevrolet Corvette (L82) 350 cubic inch V8 – 250 horsepower

• Chrysler 400 cubic inch V8 – 250 horsepower

• Pontiac 455 cubic inch V8 – 250 horsepower

• Chevrolet Camaro Z28 350 cubic inch V8 – 245 horsepower

• Chrysler 360 cubic inch V8 – 245 horsepower

• Chevrolet 454 cubic inch V8 – 235 horsepower

• Chrysler 440 cubic inch V8 – 230 horsepower

• Oldsmobile 455 cubic inch V8 – 230 horsepower

• Pontiac 400 cubic inch V8 – 225 horsepower

• American Motors 360 cubic inch V8 – 220 horsepower

• Cadillac 472 cubic inch V8 – 220 horsepower

• Ford/Lincoln 460 cubic inch V8 – 220 horsepower

• Cadillac 500 cubic inch V8 – 210 horsepower

• Oldsmobile 350 cubic inch V8 – 200 horsepower

• Pontiac 350 cubic inch V8 – 200 horsepower

• Buick 350 cubic inch V8 – 195 horsepower

The Q-code engine was not smog certified for California for 1974; California certification was a complete separate process from federal certification. Therefore the Q-code engine was not available as an option in cars sold in California. The Q-code 351 was standard equipment in Panteras however, not an option, and California was the largest market for the Pantera. Therefore Ford re-documented all 1974 Panteras destined for California as 1973 vehicles in order to get around California's 1974 tail pipe emissions certification.