Having a hard time locating dash vents for a 73, the ones that sit on top of the dash.

Was thinking about having them made with by a 3D printer service.

anyone use such a service?, would probably be cheaper to run a dozen, than just the 2 I need.

Thoughts?

Replies sorted oldest to newest

Maybe something like this;

http://www.ebay.com/itm/DASH-V...AOSwiDFYM4P7&vxp=mtr

Make sure it is UV stable and can handle the interior temp of the sun load on the dash. Sounds silly on the temp, but some of these 3D materials will only hold dimension to about 110 F.

Often the part needs more hands on attention to get right than some realize. Once the part is made a mold can be made. With a mold, a part can be casted of different materials. LOTS of opportunities!!:

I sent you a pM, would be interested in knowing the price.

Thanks

Jay

https://panterapartsusa.myshopify.com/products/13010A

$92 is a bit high for that.

quote:Originally posted by Perry H:

I found another great application of a 3D printer. These vents looked bad when they were new and the silver paint looks like it is applied with a brush or a toothpick...

https://panterapartsusa.myshopify.com/products/13010A

$92 is a bit high for that.

I believe these Vents may have come from a early 70s Lincoln?

Hmm... unfortunately I do not have source for vintage 1971 Lincoln Continental vents.

(But thanks for the hint. I will keep looking)

Unfortunately, they seem just as hard to find and as expensive (a dirty broken one on ebay is $25).

or have you thought of calling LincolnLand

I think it would be fantastic if all old cars (Panteras included) had a database of CAD files for 3D printing spare parts. This seems like a perfect application for it.

I now have the program so they are 1/2 price from now on! :-)

As an aside, these were ALSO Ford pieces that are not available as individual pieces.

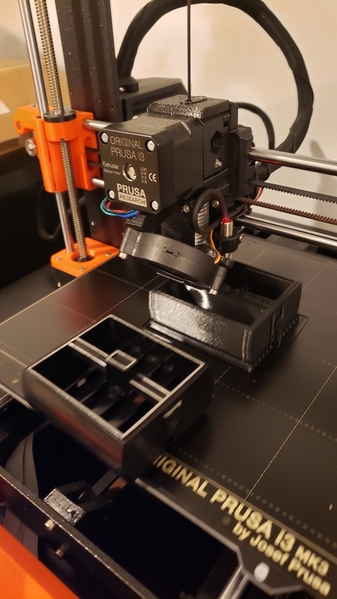

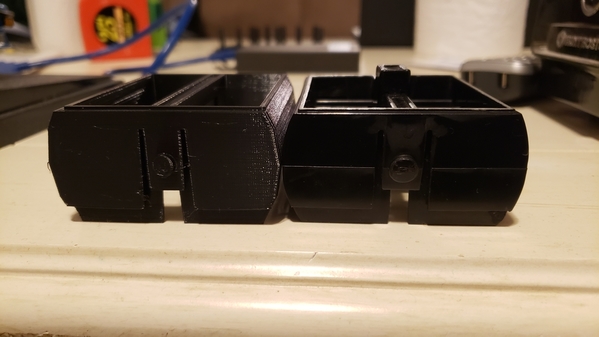

FWIW - I have my own printer now.

I have not made anything for the Pantera yet, but I did print a seat release handle for my wife's car and a gear for an old pencil sharpener. ![]()

We 3D print the cabinets for our small monitor speakers. Our biggest challenge (other than the time it takes to print) has been with consistent surface finish. If we achieve a nice finish one side then usually the adjacent side isn't the same. All the 3D printed cabinets are now sanded, filled, sanded then painted. Higher resolution printing takes even longer and surface finishing is still required.

I suspect your vents will need to be, at very least, sanded and painted with UV resistant paint. Also, research the different plastic filament that is available. Different companies have standard and unique blends. Check the thermal specs.

Mike