I would suggest a drain plug still and a bung that will accept a larger than stock fuel line. Maybe that bung isnt required with an in tank pump, but a drain plug I still think is necessary. Reinforced so it doesn't risk damaging the tank like the stock one can.

The 2" or so balance tube between dual tanks needs only one fill position to fill both tanks at once, and one fuel pump to feed the engine. Less complication= fewer failures.

@bosswrench posted:The 2" or so balance tube between dual tanks needs only one fill position to fill both tanks at once...

Of course....I didn't think of that!

The lower (balance) hose between dual tanks doesn't need to 2" + unless you are building a race car where you need to fast fill. In either case the upper (vent) hose must also have enough flow for the displaced air. For a street car, safety must also be a priority. In case of a bad accident I would rather have a -16 line severed than a 2"+ line.

Arrange the tanks so the floor of the secondary tank (without the fuel pickup) is about 1" to 2" higher than the primary tank (with the fuel pickup). The primary tank will act like a sump and also have provisions for the sending unit. The top of the tanks should be level. You can also design a small sump into the secondary tank.

For use in a race car, dual tanks with a large lower (balance) hose will act somewhat like one big tank. Driving at a racetrack you are wearing a fire suite and have 15 to 20 seconds to get out (in case of an accident) plus emergency personnel near by. Sorry for the gloom. I know a bit about fire. I designed and developed fire and life safety equipment for over 30 years.

We did talk about the drain plug as these are hobby cars to a lot of guys and may sit. A robust drain is required...lol...

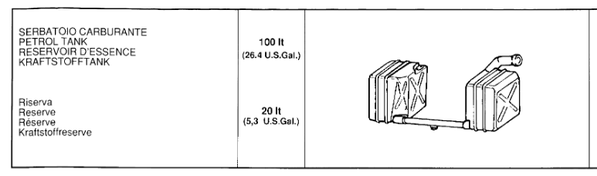

Also, here's a pic of the Pantera Performance aluminum fuel tank next to an OEM tank. The Pantera Performance tank uses a Fuel Safe bladder and foam, which is why the side of the tank needs to be removeable. It also uses a Centroid fuel level sending unit.

Attachments

Good stuff....

Until y'all get around to pulling the engine, transaxle and old fuel tank out of the Pantera, to replace it with one of the much better aftermarket assemblies, have you had trouble getting the stock drain plug out of your OEM tank? I'm one of those unfortunate owners that got a car with the drain plug apparently corrosion-welded in place. We've owned #4366 for almost 40 years and even with all my tools and a heated shop, I've NEVER been able to remove the OEM drain plug!

The tank steel is so thin that putting a correct size socket and a breaker bar on, I can see the tank bottom begin to bend, ripple and distort enough that I'm afraid I'll literally tear the tank bottom open. But the plug stays in place (no leaks, though). So at this point I see two simple choices: drill the thing out from underneath & retap the threads, or try a friend's method with a big air ratchet. He sets the air pressure low enough that the tool just sits there and chatters away- he swears that after 4 or 5 minutes (with periodic air pressure adjustments), most ANY drain plug will come loose without tank damage. Me- I gave up after a few minutes of unbelievable noise from the 2-horse compressor and the air gun.

I don't like the idea of drilling under a tank with a half gallon or so of residual gas in it (from my siphoning efforts)- seems like when the drill bit STARTS to break thru and fuel comes dribbling out onto my running ELECTRIC drill, I'm not in a healthy place.... Anyone got a better suggestion that worked for you? Not theory but that actually worked?

J DeRyke

Same exact experience. I leaned on my drain plug and the bottom of my tank started to distort. I left it alone.