Hello, I am considering purchasing the MSD Atomic fuel injection kit which has a feature to run the radiator fans and control ignition timing as it is self tuning. My concern is that it requires a coolant temp sensor before the thermostat and the only one I know of is in the block for the temp sensor. It also requires welding a bung for O2 sensor in one of the headers. Does anyone have any experience with the Atomic FI and or have a secondary coolant temp sensor location suggestion?

Replies sorted oldest to newest

You could purchase a new thermostat housing that has a fitting for a temperature sensor if MSD requires a second temperature sensor for the radiator fans. I had one that was for a 429 Ford and it fit on my Cleveland block. I don't see why it would be that important to have it mounted in the block if all it was going to do is turn your cooling fans on, which in a stock Pantera are activated by the temperature sensors in the radiator. Any of these aftermarket EFI systems want to have an accurate water temperature indication to determine when the ECU goes from open loop to closed loop operation. The water temperature sensor will also control the warm up fuel air ratio mixture. Welding the bung into the exhaust is common for any system that I know of unless it is some racing set up. I am using a F.A.S.T 2.05 system which is port injected, but I know of a couple of people that have the MSD Atomic and they like it. If you use the water temperature sensor port in your block for the EFI coolant temperature, you are going to have to find another place to get you water temperature gauge indication from. The original Pantera surge tank sensor location wasn't the best place to take that reading from, but if you put that sensor in your water pump, then your gauge will read lower than your actual water temperature is.

@jffr posted:You could purchase a new thermostat housing that has a fitting for a temperature sensor if MSD requires a second temperature sensor for the radiator fans. I had one that was for a 429 Ford and it fit on my Cleveland block. I don't see why it would be that important to have it mounted in the block if all it was going to do is turn your cooling fans on, which in a stock Pantera are activated by the temperature sensors in the radiator. Any of these aftermarket EFI systems want to have an accurate water temperature indication to determine when the ECU goes from open loop to closed loop operation. The water temperature sensor will also control the warm up fuel air ratio mixture. Welding the bung into the exhaust is common for any system that I know of unless it is some racing set up. I am using a F.A.S.T 2.05 system which is port injected, but I know of a couple of people that have the MSD Atomic and they like it. If you use the water temperature sensor port in your block for the EFI coolant temperature, you are going to have to find another place to get you water temperature gauge indication from. The original Pantera surge tank sensor location wasn't the best place to take that reading from, but if you put that sensor in your water pump, then your gauge will read lower than your actual water temperature is.

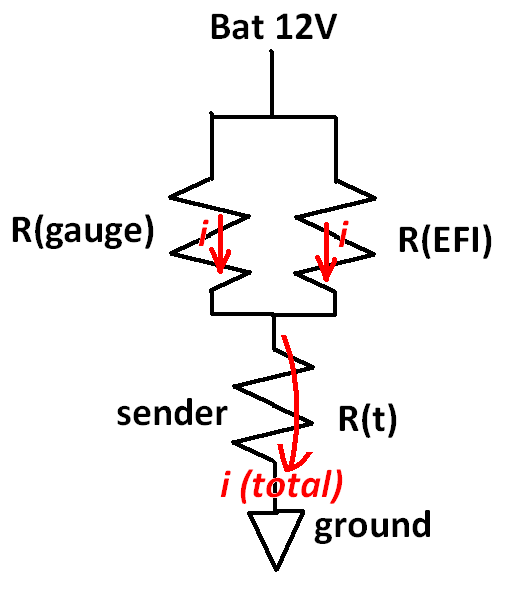

Could You not run Both wires from the sender for the Temp Gauge and the Temp Sensor? Or will the sender not have enough "Power" to Power both Items? I don't know much these things. If I where to install a EFI, I would need to pay a Expert to install it!

You might also want to consider Holley EFI's Sniper system:

https://www.holley.com/brands/...njection/sniper_efi/

Mind you, you'll still need an O2 sensor bung and a second coolant temp sensor. Although the Sniper can control your rad. fans, the coolant temp sensor is for the ECU. I wonder if you could find a tee fitting that would give you enough room for the second sensor?

You can't use the same water temperature sensor for your EFI water temperature indication and you gauge. The sensor output value would be different.

interesting question (can one parallel devices to one sender)

the "power" comes from the devices (gauge & EFI). since they both get power from the battery, they would SHARE given the sender will draw current based upon the temperature. therefore neither device would sense 100% of the current (which is what it uses to determine temperature)

or as JFFR said, NOPE

(or maybe, but with some consideration after performing a whole lot of testing and measuring))

Attachments

If you use the EFI ECU to control your radiator cooling fans, you will have to run a wire from the ECU to the radiator cooling fan relays. Keep in mind that if your EFI coolant temperature sending unit fails, then your radiator cooling fans will not come on. In my opinion, leaving the radiator cooling fans on their own circuit is a better option. Putting the EFI water temperature sensor in the block will give the ECU a quicker temperature reading and get you into the closed loop mode sooner, but it won't be that much quicker than having the sending unit in the thermostat housing.

I have the MSD Atomic EFI on my car. I did not install it.....had a buddy do it. It works very nicely. I have no complaints. Good throttle response....starts first crank. Unfortunately I don't have any answers regarding the temp sensor.

Is the engine in this Pantera basically stock or does it have a larger camshaft and higher compression?

My engine was rebuilt about a year ago and is basically stock. Hydraulic lifters and Comp cam # CL32-221-3 which has duration 268/268 and lift of 494/494 and tops out at about 5500 RPM.

That sounds like a mild build, which should be good with the basic tune that the Atomic unit would have. You might want to watch your fuel air ratio because sometimes a built up engine wants a bit of a richer fuel mixture than a stock or very mild build. If you feel it leaning out at certain speeds, you might have to richen it up a bit. The last thing you want to do is have your engine going lean because that can lead to damage. I found that out with my EFI system when I was at lower elevations and at about 2600 rpm in 5th gear. My engine didn't like the operating around 14:0 to 1 ratio, but dropping down to a bit took care of the problem. Of course, I am running a somewhat radical built.

I ran an MSD Atomic with my engine. Put your gauge water temp sensor in the water pump and the MSD Atomic water sensor in the regular block location. The Pantera water temp gauge is not exactly accurate, unless you get Jon Hass's calibrated sensor. That way the Atomic will know the coolant temp correctly at all times. I would not worry about the Atomic controlling your cooling fans. If the Atomic water sensor failed I doubt the engine would run anyway and you could control both fans with more accuracy. A better solution would be Jon Hass's fan controller. His unit uses modern sensors in the radiator with a low speed - low current start of the fans and proportionally changes the fans speed depending on temperature minimizing current draw and noise.

When fitting the Atomic throttle body consider spinning it around so the throttle lever is on the right. The fuel lines then take an easier line to the left side. You might need to lengthen your throttle cable though.

You will need a tach adapter if you are using the MSD ignition box and want to run your original tach. I would use Jon Hass's tach adapter, my MSD adapter was not accurate and eventually failed. Better yet uses Jon's ignition box and a lot of your worries are solved.

I did some testing years ago and switched my water temperature sending unit location from the block to the water pump. The result was almost 20 degrees cooler indicated temperature on the gauge, which was not correct. I also used a laser temperature gun to back up the results. All of my gauges are electric Autometer units, so that eliminated the Veglia/Ford sending unit mismatch problem. If you still have your water temperature gauge sending unit in your surge tank, then leave it there and put the Atomic water temperature sensor in the block. The EFI water temperature sending unit's primary function is to richen the fuel mixture while the engine is warming up and to switch the unit over from open loop operation (warm up) to closed loop operation (normal run). I don't know if the Atomic EFI has an option to add more fuel and increase the fuel air ratio if engine temperatures get too high, but my F.A.S.T XFI system does. It comes down to a matter of choice as to where to locate each sending unit, but the engine block location gives you a very accurate real time water temperature reading, which in my opinion is best to have for your temperature gauge. If you install a thermostat housing that has a temperature sending unit plug on top, your EFI water temperature sending unit can go there.

Thanks for all of the replies and good info should I ever decide to install the FI system however for now I have played with my Carter AFB and ignition timing and I have it starting and running well with the exception of a occasional slight hesitation when going from coasting to back on the throttle which I can live with for now.

Since I am am not spending all that money on the FI system this Friday July 3rd I pulled all of my a/c components out except for the evaporator and visited a automotive a/c supplier where I sourced and bought a GPD Sanden style 508 compressor, an adapter bracket from York to Sanden that I had to grind away the back of the adapter plate so it would clear the existing a/c bracket mounting tab and block in order to fit properly, new condenser that fit in the existing fan shroud, new hoses with same ID and a smaller OD which made it easier to run lines through center console and dash, a new drier with high pressure switch, new expansion valve, tar tape, and all on the fittings. I have to use flared fitting at the existing evaporator and will use copper crush washer to help make the seal and all other hose fittings will be o ring ones. I cleaned the evaporator with a disposable flush bottle Kit from Autozone.

All that is left to do is to take the car back to the a/c supplier to have all of the hose ends crimped and to wire the high pressure switch and clutch and then evacuate the system, check for leaks, and If no leaks to add about 3 more ounces of pag oil since the compressor comes with 6.42 ounces of pag oil in. Lastly add the r134a.

I fought with the c clip for the expansion valve sensor and it fell into the air box so hopefully it won’t cause any issues. I ended up used copper plumbers tape and copper wire to secure the coiled up sensor from the expansion valve to the evaporator suction pipe. I then wrapped it with a/c foil tape and if no leaks I will put the tar tape over it to help with condensation. Fighting that c clip and eventually losing it was the worst part of the job as it is not fun working under the dash.

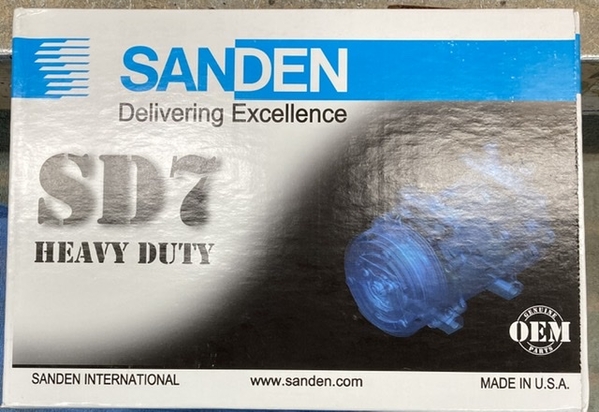

For what it is worth, I have never heard anything good about the Sanden ...style... compressors. I have heard bad things about them, though.

To clarify, a genuine Sanden does not have a history of failures. However, many, if not most, of this style of compressor offered for sale are not genuine Sanden; but you will see the advertisements listing it as a Sanden “style” compressor. Very misleading description for a generic, made in China, version of the genuine Sanden compressor.

my 2¢

Larry

Attachments

I have heard that to Larry however the A/C supply guy said he has sold many of these GPD units with very few issues. Thanks for your 2C as I do value your opinion. Louie

https://www.carid.com/1987-jee...ssor-2118700217.html

FWIW, I have used more than several Sanden compressors in AC installs w/o a single failure. Perhaps a case of "Treat me right, I'll tell someone else; treat me wrong, I'll tell the world."

JT

I have been using a Sanden air conditioning compressor for years and have not had any problems. I did installed a high low pressure cut off switch in the system which prevents damage to the compressor.

Another FWIW, I upgraded the A/C in my Pantera with a R-134a Sanden compressor in 2003, and the A/C still blows cold even though I haven't touch the system since then. It's just that the blower doesn't push enough of that cold air through the two little vents in the middle of the dash to compensate for all the heat sources (ambient, cooling tubes, windshield, firewall heat soak even though insulated), especially on a 90+ degree, humid day. If the A/C is on when I leave the garage, it can usually keep up, but if the car has been parked in the sun and heat all day at work, cruise-in or car show, the A/C just doesn't have enough throughput to cool the cockpit down during a relatively short drive home.

Image is from August 2003 during first A/C test after charging in garage at high idle speed.

Attachments

I believe Larry is saying a true Sanden compressor is reliable and recommend however I am gambling by using a knock off Sanden Style compressor made by gpd.

The clue is in the word "style". This is an indication that it is not a real Sanden unit but rather a china made clone with lesser quality at a lower cost. If you cruise the internet you will find many sanden style compressors for sale but few real ones.

Just an update on my ac system: I finished the installation over a month ago and it is working fantastic. So happy that the brass adapter fittings from flared end to o ring fittings along with copper crush washers allowed me to keep the original evaporator in the dash after flushing it completely. Everything else was replaced with new. The sight glass in the dryer tells me the system is holding pressure and apparently not leaking. I drove the car yesterday in 100 degree SoCal heat and the engine temp was around 195 and I only needed the ac fan on the lowest on the two speeds to keep me cool. Finally have ac after 30 years of being the caretaker of my dads car.

Congratulations on a job well done. May it serve you flawlessly for many years to come.

Larry

Awesome. I have that on my list of TO DOs right now, and debating whether or not to go R134 or not. Been trying to educate myself and read all the posts and tech articles about which way to go. All my hoses etc look good, have all the parts, but I think I'd want to get a new dryer and condenser regardless. I may be hitting you up for some tips...