I just spent more time than I ever wanted under my dashboard of my 72 pre-L removing the clutch master cylinder. I finally removed it with the help of two different people who eventually quit after the lower bolt. I managed the upper bolt single-handed. I tore the dust boot in the process. BTW I have the long cylinder, not the shorter one for the force reduction rig.

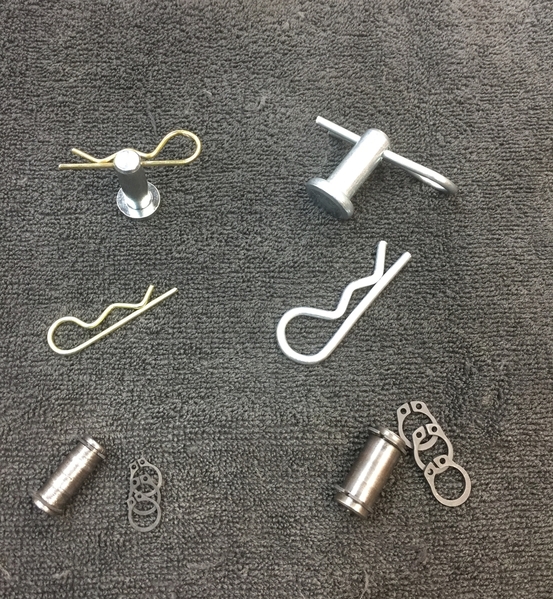

The thought of replacing it was daunting so in a stroke of genius I decided to "convert" my bolts to studs by fixing them in place with JBWeld. I cleaned the interior firewall mounting area using a brass brush and cleaned it with solvent. Ditto the bolt heads. I applied the prepared JBWeld to both the firewall and bolt head. I held the front trunk shaft part of the bolt with vice grips and ran a nut down to the firewall to press the bolt head in place. After 24 hours cure time I tested it and that JBWeld really fastened the bolt in place. Yesterday I installed the rebuilt cylinder and tightened. One person job and solid. Before doing this I did a test with a piece of drilled aluminum plate and a bolt/nut to be sure it was strong enough. That stuff really holds. Now it's on to linkage connect and bleed the system. Roads time.almost here.

I swear DeTomaso built the whole car around that upper bolt.