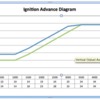

I am using the stiffest Springs on my Pertronix Billet Distributor and the advance sets in @ 2000RPM. Under acceleration I have a slight pinging just at that moment up to about 2500RPM. It is otherwise fine in the full range beyond 2500RPM. Initial timing is 14° and max advance is 20° to a total of 34°

My question is if anyone has been fighting the same issue and if it will be a recommended solution to drill away some material on the Weights to make them lighter? Alternatively I could use some stiffer Springs but not sure were to look. I called Pertronix tech Line and they do not provide stiffer Springs than the ones I already have. The Tech Rep told me that their components are similar to Chevy/Delco early 70´s Distributors and perhaps there are some stiffer aftermarket Springs available??

Obviously my objective is to delay the advancing by 300-500RPM.

any suggestions are welcome.

Jan

Original Post