Stock 351C, FULL Hydro ROLLER/Crane.

Current Distributor is Motocraft 12 127 (single braker point). NOT SURE IF THIS IS STOCK!! hence questions++!

Building Street engine up to typ 6000RPM/min/max ..once in a while..to kill a Porsch on the German autobahn...

I want to keep the distributor as it fits nicely from height with my Trick-flow Heads and Edelbrock RPM Dual intake, Holley ...and the Air filter ... small spacer < 1"

here my questions:

1) Motocraft 12127 good enough?

1.1) ....I want to convert to Pertronix/Durasparc etc.. ????

1.2) any recommendation for electronic pick up? for MOTORCRAFT 12 127...

1.3) should I go for a different Distributor PRODUCT.. Height is the issue

as the MSD as sample (to my understanding) are TOO hight, should be electronic ?

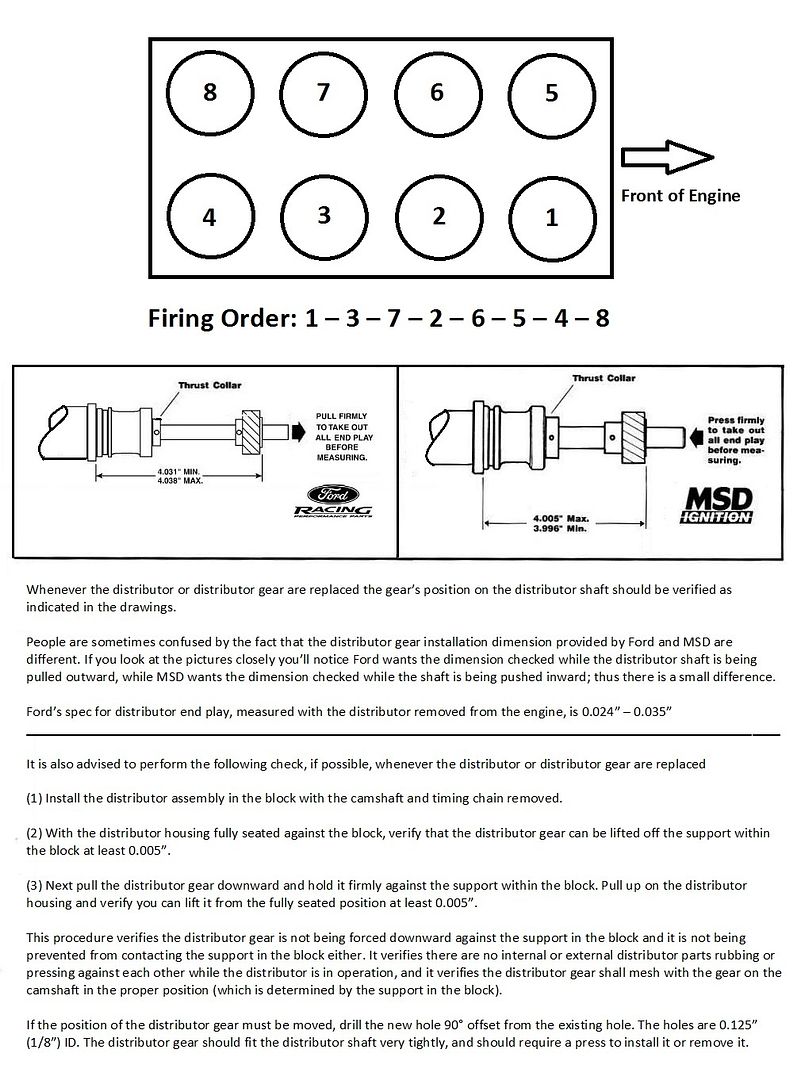

2) Distributor Gear:

2.1)here is a big confusion in language I guess. Crane asks for "Steal"

gear vs "IRON! Well sorry WHATS is STEAL? I do NOT want to go now

in metallurgy, but:. Sample: the 351C BLOCK is in Germany "Guss Stahl"

(very hard) vs. "steal on the car boddy. There is NO IRON in any Car in German language,

it is ALL Steal of different grade....

MY drice gear is WHAT???? see picture To me it is definatley "Guss Stahl" as VERY hard..

CAN I USE IT HYDRO/Roller DRIVE??? ..hence good enough? as it look good

(roll pin replacement, and ARP drice shaft

TX for help

Matthias