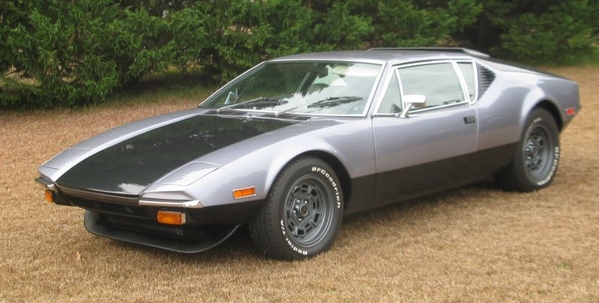

I would like to take some detail pics and try doing vids, BUT the temptation to just DRIVE overcomes.

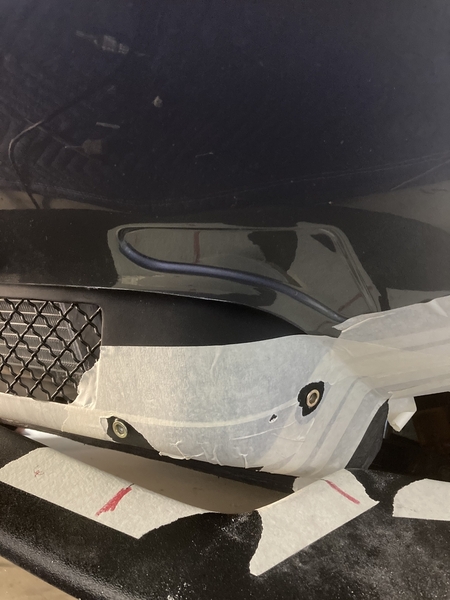

5177 is now stored in a different building rather than the shed it stayed in 20+ years. I added a centering line and delineators to help keep me straight.

open the rollup and fire it up, walk the exit to ensure it is clear

open the rollup and fire it up, walk the exit to ensure it is clear

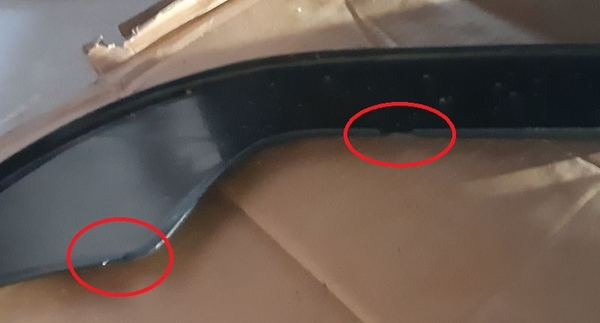

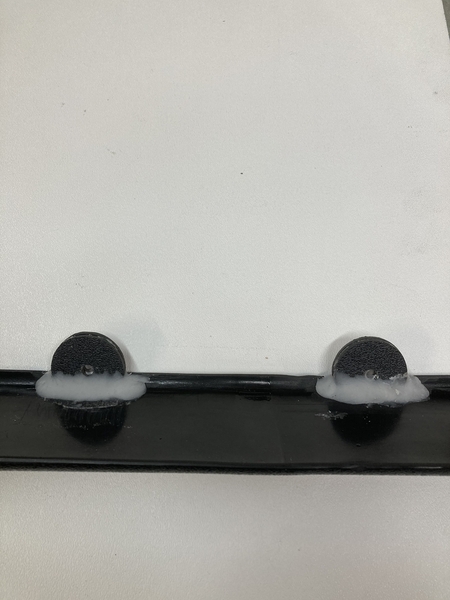

back off the concrete pad and into the yard. did show, but I have to angle due to transition and spoiler draggging.

back off the concrete pad and into the yard. did show, but I have to angle due to transition and spoiler draggging.

down the long dusty path to the paved road.

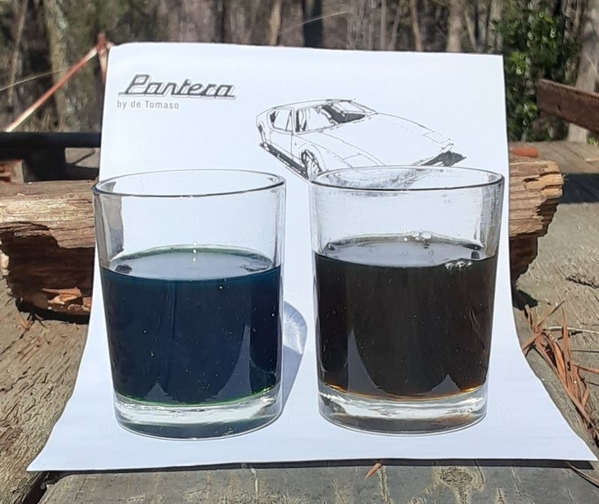

head into town and first fill up of 91 non-alcohol.

went for about an hour just cruising the back roads. the engine seems to like ~2200 rpms, giving me ~55 mph in fifth. I found listen to the tone makes an excellent "cruise control". Having to down shift as approach a stop is a little strange, but not engine braking but just keeping rpms up without just coasting.

went for about an hour just cruising the back roads. the engine seems to like ~2200 rpms, giving me ~55 mph in fifth. I found listen to the tone makes an excellent "cruise control". Having to down shift as approach a stop is a little strange, but not engine braking but just keeping rpms up without just coasting.

Pulled back onto the dusty drive. I got the Panther mascot, but no "Farrah Fawcett"

can't wait for tomorrow's excursion. Would like to drive to diner, but between the altornator might not keep up with headlights and more so my night vision I won't try