quote:

Originally posted by PanteraDoug:

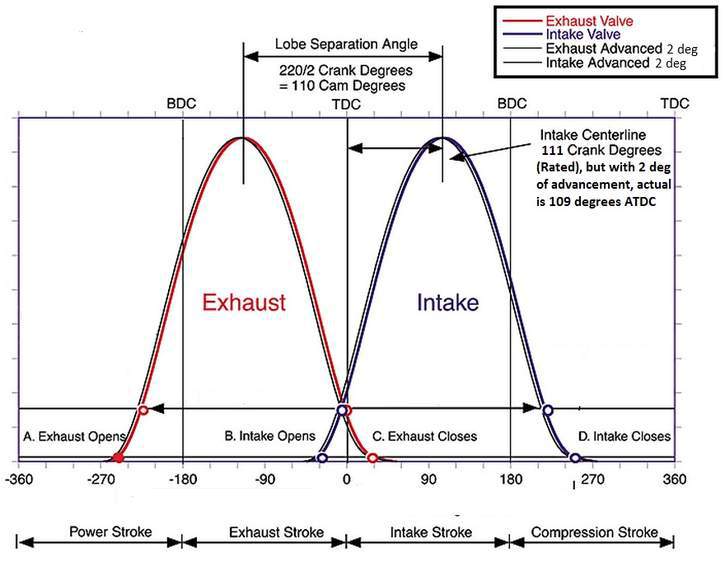

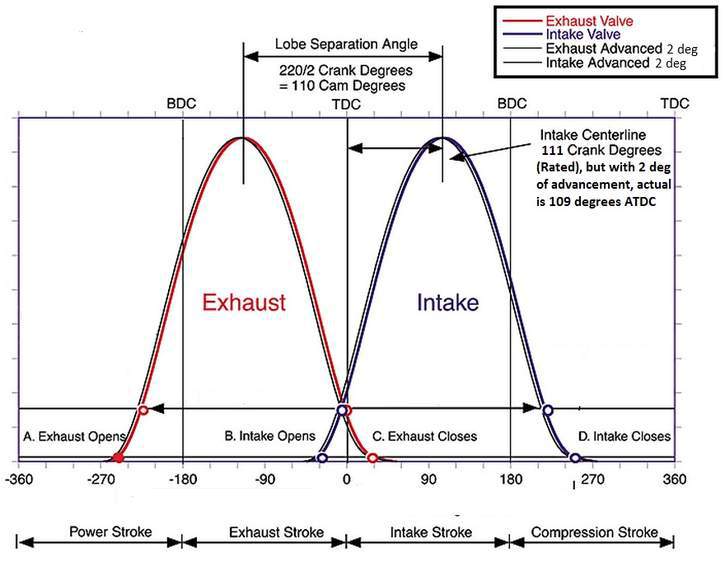

I have never seen a graph of a cam lift.

The closest clearance is at maximum lift at the highest point the piston is at, unless you have invented a new form of physics?

I suppose in this era of alternative facts anything is possible? I must live in an alternate reality?

No need to invent new laws of physics, it is enough to well understand those that are known and particularly those of kinematics.

To determine the clearance between

TWO moving parts we must take into account the position of

BOTH parts and therefore not only that of the piston but also that of the valves!

Therefore, the minimum clearance is not necessarily at the top dead center simply because the valves, during the few degrees before and after the top dead center, can open or close faster than the piston goes down or up.

I do not live in an alternative world but it is not the first engine that I rebuild by modifying it and I never affirm anything without being absolutely sure of it. I also avoid making fun of people when I know badly what I'm talking about.

If you've never seen a lift curve, it's that you still have a lot to learn about engines.