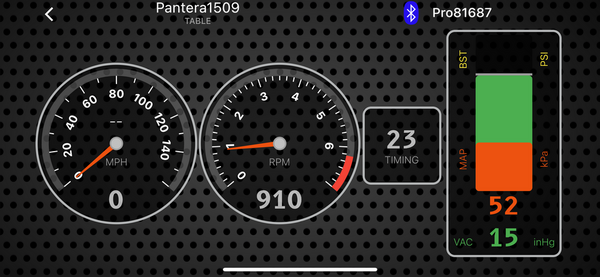

The engine is pulling a steady vacuum reading. There is very little fluctuation.

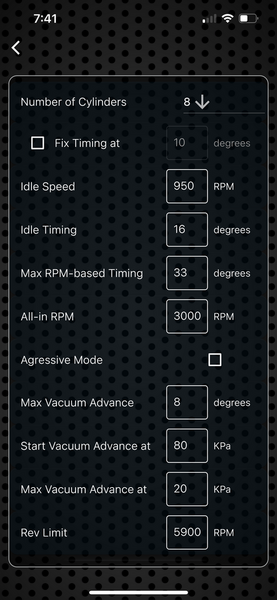

I replaced the blue plastic plug in the manifold with a brass plug. The blue plug was not tight. I also replaced the thick carb gasket with a normal gasket. The dieseling did not change. Normal advance on this engine 16 degrees. I tried decreasing that to 10 degrees and no help.

The best way I have to stop the engine at this time is to turn down the idle screw until it stops running.

After putting in the normal carb gasket the throttle cable and linkage are dragging on the manifold. Hence the reason for the thick gasket. It looks like I will go back to it or use a spacer and two gaskets.