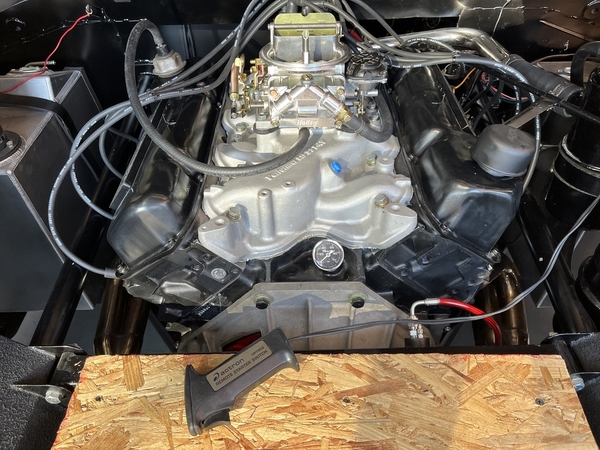

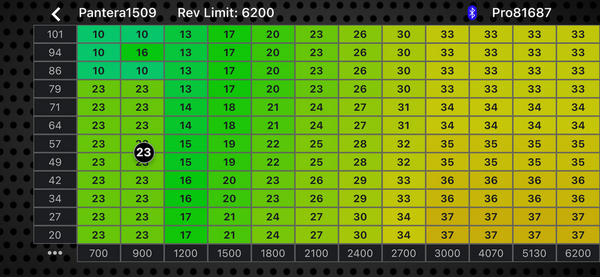

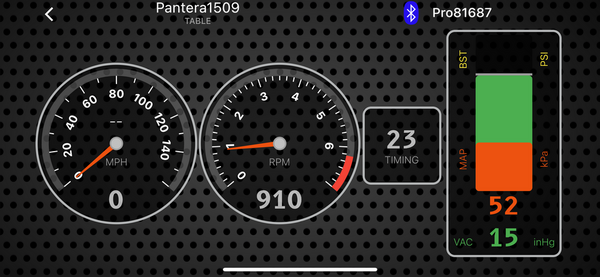

I am working on a Pantera with a freshly rebuilt engine. It starts, runs, and sounds great. It also idles nicely. But on shutdown it diesels badly. It has a new Holley 750 with vacuum secondaries, electronic ignition, Autolite 25 spark plugs, closed chamber 351C heads with stainless valves, stroked to 408 cubic inches, dished forged pistons, compression ratio 9.5 or 10, hydraulic roller cam, and adjustable roller rockers.

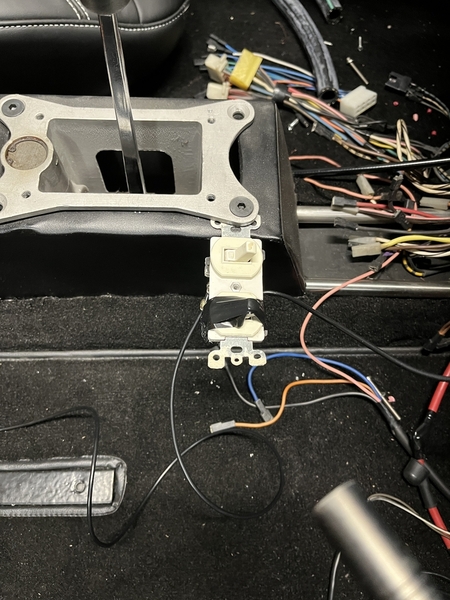

As a temporary workaround I made a steel sleeve that slips over the idle stop and I can pull it off to kill the engine. I just finished it and I'm not sure how well it will work to keep it from dieseling. Its initial test seemed okay.

I tried a different carburetor on the engine and it dieseled the same way on shutdown.

I am at a loss on how to proceed with this and I am looking for suggestions on how to proceed. Thanks in advance.