yes, this modification was successfully done by an owner in Finland back in 2017. His forum handle is kimk and here is a link to the thread of his restoration. The link should open on page 5 of the thread.

https://pantera.infopop.cc/topic/new-pantera-project

UPDATE: I see the above link takes you to page 1 instead of page 5. 🤷♂️☹️

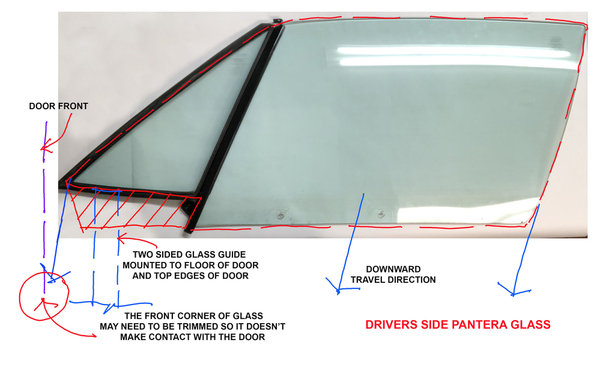

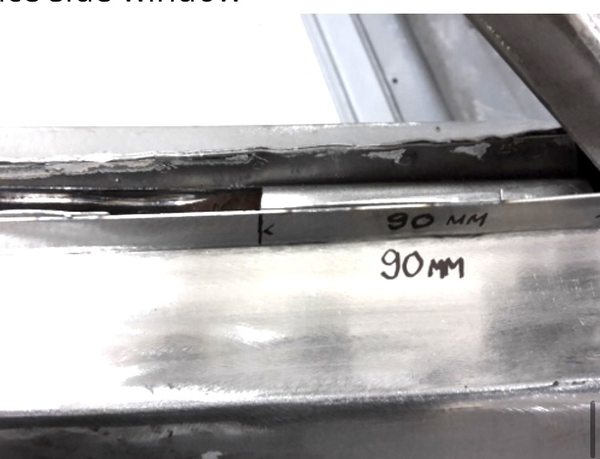

As can be seen the glass could not fill the entire opening.

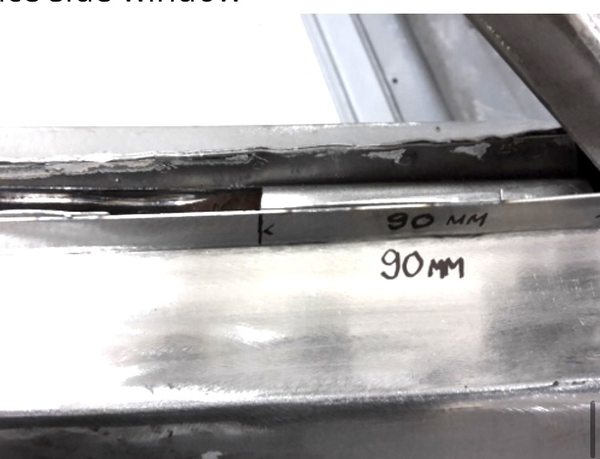

Some sheet metal below the OEM vent window needs to be removed to allow an opening for the glass and provide a proper metal profile for the door whiskers to attach to. This photo shows the metal removed in all but the forward section.

The new forward vertical window channel is sourced from the OEM forward vertical window channel.

Not shown in his thread, but a new forward in-the-door metal U channel will need to be installed for the extended glass to ride in.

The top U channel felt channels and the felt door whiskers are issues, but not serious problems.

IIRC, the upper door frame channel for the quarter window gasket is just a continuation of the upper door frame channel for the roll-up window; longer felt channel is readily available.

As shown in one of the photos above, there will be some challenging metal removal in the lower quarter window area. Some precision removal (Dremel with cut-off wheels?) of excess metal will leave metal that matches the original door metal profile. Longer felt whiskers are readily available.

His description of the process is far from detailed, but of note was his need to correct U channel contour due to incorrect glass curvature.

at this point in time a PM to Kim is the logical first step for those interested in this modification, as the biggest stumbling block to the project is the custom glass. At the time of his project Kim said the cost for the two custom glass pieces would be €740 plus shipping costs.

there may be different approaches than Kim’s that would prove satisfactory, but this is clearly a major project with major roadblocks to solve.

so, who is going to send that PM to Kim?

Larry