I searched but didn't see this addressed.

I decided to bleed my clutch slave and while I was at it, check pushrod length.

It was way too long at around 3.45" instead of 3.07 to 3.09. The clutch has always engaged very near the top of the stroke (away from the floor) and I guess I got used to it.

I couldn't get it to 3.07-.09 without removing the bolt. Are there any variations in these things?

I adjusted the stop bolt gap to .102" but I don't get what that does. Is it because the pushrod is still (slightly) too long?

Replies sorted oldest to newest

When you disconnect the spring , what distance is the ,, free"stroke ?

Simon

im replacing slave cyl. this week following its a pain to get to bolts were turning under dash.

John,

Someone may have set the clutch lever arm incorrectly onto the shaft. It sounds like they set it too many notches to the rear. This would have the effect of requiring the pushrod length to be too long. Sharkey wrote the following today on another posting:

"Pull the arm off the cross shaft, set it 12 o'clock straight up (if it's not already) or even one notch to the rear it'll still work."

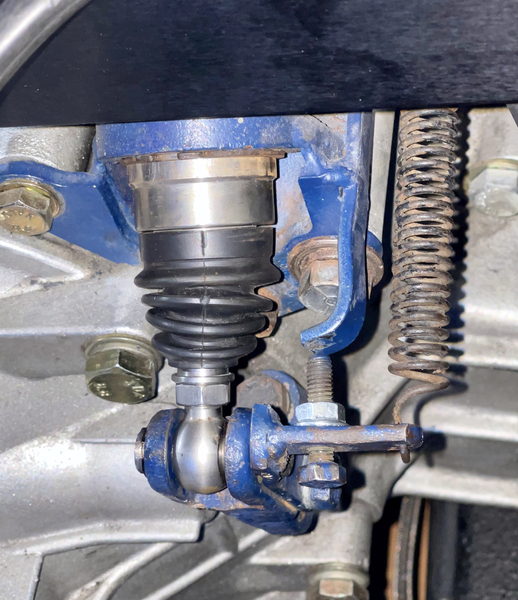

Each notch to the rear of 12 o'clock requires the the pushrod to be lengthened. I was working on this today and noticed it is easier to get everything in place by going with more notches to the rear. That may have been what someone previously did. Now I know to start on this with Sharkey's advice. You may have to remove the bottom snap ring on the slave to get this to line up and getting the snap ring back on will not be fun. It might be best to temporarily disconnect the external return spring that you can see in your photo. And also loosen the stop bolt in your photo.

FYI, the return spring and the stop bolt seem to be used to set throw out bearing clearance. If all of this seems a little overwhelming you are not alone.

Regards, Steve

Thanks guys. @simon, there is no free stroke. I guess that points to the arm being positioned wrong. I'll crack into it and see what I find.

@jmardy posted:Thanks guys. @simon, there is no free stroke. I guess that points to the arm being positioned wrong. I'll crack into it and see what I find.

adjust the lever one tooth

Can you inspect the thicknes from the clutch disc ?maybe also your clutch friction material is gone.

when drive into a high gear on low rpm , go full throttle , when the engine turns quick on high rpm but speed is the same , clutch is gone also.

Simon

David P, the simplest way to remove slave cylinder bolts by yourself is to clamp a vice-grip pliers on the nut. Then when you're in the front trunk with a wrench, the pliers will rotate, hit something and you can unscrew the bolt.

Next, when trying to get the snap-ring off the clevis that holds the slave shaft, use magnetic tools. What usually happens is while trying to dig the tiny snapring out, it pops "somewhere" so you'll never see it again. Some shafts have a head, some have two snap-rings. They are not commonly available if you lose one.

Once the snapring is out, you'll likely find that the short mild steel shaft that holds the clevis has worn a groove in itself from lack of lube, preventing it from being pushed out easily. That's why we usually drill a 1" or 15/16" hole in the toe-box in line with the shaft- so one can reach through it and pull the pin out with long-nose vice-grips. That hole can be plugged with a std plastic plug available at most good hardware stores. And you can route your emergency hood release cable thru the hole, too.

Thanks Simon. The clutch doesn't slip and is only a few thousand miles old so hopefully no harm done. I'll inspect and report back.

None of this would explain why I can't get the pushrod length short enough. Could this be an aftermarket one that is different?

In the photo above the stop screw is still in place as well as the return spring. Both could inhibit pivoting of the arm. And the stop screw looks to be extended pretty far out, perhaps at its maximum. Maybe remove both of those and check again for free play. I see that the slave cylinder in its correct location and I am guessing that you removed its pin.

Did you replace the clutch yourself ? And have check the freeplay from the trow out bearing and the pressure fingers from the pressure plate ?

Simon

PO had it done as part of engine rebuild so I know nothing about what was done.

If I understand it correctly, the free play should be felt in the clutch arm (with the return spring removed). Yes?

If there isn't any, what next?

Yes, free play is easily detected at the arm with the spring AND stop screw removed, assuming there is actually free play between the bearing and the pressure plate fingers.

Your stop screw might be pushing the bearing onto the pressure plate.

@jmardy posted:

If I understand it correctly, the free play should be felt in the clutch arm (with the return spring removed). Yes?

If there isn't any, what next?

Yes ,freeplay with the return spring removed.

next , pull the transaxle and check the trowout bearing /fingers distance .

maybe chance the trowout bearing to a adjustable ( spacers)

also possible that one of the fingers of the pressure plate has a failure .

have this seen before , what brand of clutch ?

Simon

Thanks guys. Not to be too daft but the stop screw is just sitting in space,not touching anything. :confused

No idea what's in there as far as clutch/flywheel parts.

pull the transaxle , a 2 hr job , inspect and replace takes 3 hrs

Agreed. After scrutinizing the photo I can (barely) see the gap between the stop screw and its stop. It looks like the throw out bearing is not setup correctly with the pressure plate.

If it takes more than 5 hours to pull and replace the transaxle you can bill Simon for the overage.

Apparently Mike Drew did it in a hotel parking lot once. ![]()

OK, crap. I'll try to gather the courage. Hell, if I can rebuild the top of the engine in place, a 160 pound transaxle can't be that bad.

The two previously posted pics clearly show a gap between the end of the stop screw and the stop.

Try removing the pivot pin from the clutch arm and slave's pushrod, and see if that allows free movement of the clutch arm. You may have to back off the stop screw a bit.

In an effort to keep the clutch arm as close to vertical (12 o'clock) as possible, you might try removing the jam nut on the slave's pushrod and screwing the two pieces of the pushrod together, bottoming one into the other, and tightening without a jam nut. This solved a similar issue that I had. You could also try using an actual (thin) jam nut.

YMMV

John

Bent the rear body mounting ears a little , then the ZF slide in and out easier.

losen the engine mounts a little too

take out the ZF of the car you can do alone , place it back it will be handierwith a friend

Or engine lift

To set free play: disconnect the slave push rod from the actuating arm (remove the pin), manually move the clutch arm back and forth feeling for when the fingers pressure up on the throw out bearing. Adjust the stop bolt to get the .102" free play before the arm pressures on the throw out.

There are so many combination of aftermarket slave (stock, long throw etc.) the 3.07" to 3.09" is somewhat meaningless, you probably have a long throw slave, forget about this setting!

Push on the slave piston and check the distance the slave cylinder bottoms from the actuator arm, set you push rod a little shorter so the slave is not bottomed at rest.

Check clutch pedal function and point of clutch engagement, can also check you have a minimum 0.04" between the flywheel and friction plate through the bell housing hole.

Get in, start engine, engage gear, drive happily!