Larry and Jack, there are a couple things about these drawings that interest me...

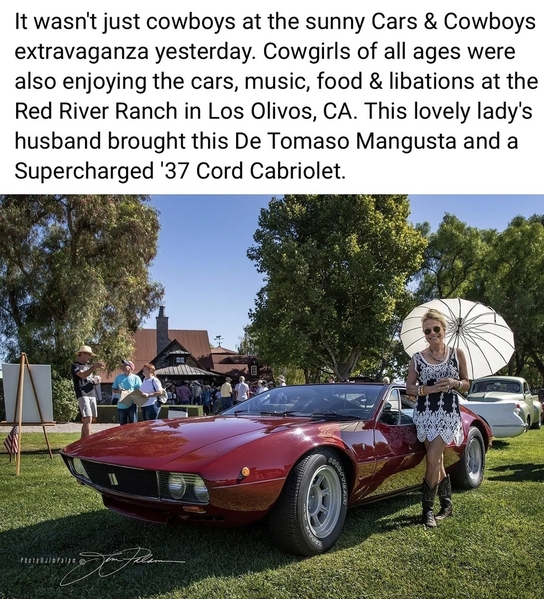

-Jack, interesting that only the very first few Mangustas seemed to have silentblocks on the front suspension...and afterwards, at least on the suspension just a thin skin of polyurethane bushing (when silentblock isolation was standard on the Maserati GTs..). But overall, hard to get less cushy than a Mangusta, I'd think...

- Larry, yeah, the pictures here in the parts book seemed to be by a cartoonist (here is an isometric picture of a nut...). The 'Silvestro leaks' show that DeT made or kept their own drawings even for parts they may have completely leveraged (eg DeCarbon shock here...even if it does show the shock is red, which nobody has seen!), even if they didn't get someone who would write text very clearly...

But Larry and Jack, where did -these- body pictures come from? I think I pulled them off the Mangusta International site 2 decades ago, and given their thumbnail sizes there were probably posted with a dialup modem.... But any idea what document these came from? Lee