The group is called "Clevelands Forever". List the value train parts and ask them to provide input on the suitability of it all.

Thanks. Will do.

It's a crappy time to do this, the parts you want and the parts that are available are rarely the same.

The ONLY good looking retrofit non-dogbone/spider lifters I can find are Howards 91168. The 91260 looks better but nationwide backorder and impossible to find.

Lunati 72335 is the same.

Hi guys. A little update on my very slow progress.

I ordered and received the Howard's 91168 link bar lifters.

The oil port in Howard's is lower than the ones in the Comp lifters and based on some (crude?) measurements I took, they weren't engaging the oil galley all the time. The Howard's do.

I installed them (with yet another set of $180 pushrods). Set lifter preload and spun the pump. Got very nice oil flow out 15 lifters, a full puddle in the top of the rockers and fast dripping or steady stream down the valve springs out of all but one. Moved suspect lifter to different bore. Problem followed the lifter. Called Howard's and they said to try a new one, so I've ordered a pair of replacements.

Now, more waiting.

Oh, I also did a leakdown test and was amazed how good it was. All 8 at the edge of green (on the good side).

So I'm encouraged, and anxious.

And really, really want to drive my new car!

Attachments

I read your posts on the Cleveland FB site. Glad its working out for you.

@panterapatt posted:I read your posts on the Cleveland FB site. Glad its working out for you.

Thanks for that suggestion!

@panterapatt posted:I read your posts on the Cleveland FB site. Glad its working out for you.

did you catch the part where the oil was changed out and replaced with 20-50 right before 'the issue' presented itself? all it needed was the correct oil for hyd-roller lifters

@4vandproud posted:did you catch the part where the oil was changed out and replaced with 20-50 right before 'the issue' presented itself? all it needed was the correct oil for hyd-roller lifters

I don't understand this comment? Are you saying that hydraulic lifters won't work properly with a 20-50 weight oil?

modern hyd-rollers don't seem to care for the heavy syrup but if you can find a 20-50 with a cSt of 15 or less it'll work. it's no secret the industry has been moving toward lighter grade more importantly more easily flowing oils for decades. it should come as no surprise that the lifter manufacturers have answered the OEM's demand for lifters that work with their lighter thinner more easily flowing oils for better performance and fuel economy.

as George might say, Not Your Grandfather's Hydraulic Lifter

I'd say that all the components need to be matched to the application, including the oil.

In an engine that came originally with a 20-50 oil from Ford (Boss 351) and a recommended fully grooved maim bearing, mixing a lower viscosity oil better be right on.

There still are little quirkies unique pretty much to a performance Cleveland and a Chevy knowledge basis is just a starting point.

Lower viscosity oils are a result of manufacturers needing to increase their fleet fuel averages as are hydraulic roller lifters since in the volumes they build in, every little bit helps.

However just like in translating a word from one language to another, sometimes "things get lost in translation".

I personally would be concerned with running just a 10-30 in a Cleveland. Forget about anything thinner.

If that's a conflict with the lifters, go to a different product. It's not compatible.

Getting 99 out of a 100 right isn't enough.

As has been the case before, one problem was masking another. Yes, the oil flow through the original lifters was sub-optimal, I did test with 10w-30 and saw no noticeable improvement.

But the real problem was the pistons hittng the Edelbrock heads, but barely. Enough to make a racket but, according to my engine guy not enough to do any damage.

Lots of lessons learned here. Had I known to clay your pistons with your new heads, it would have saved me a LOT of time, money and effort. I believed the logo on the box that said "Bolt on and Go".

Fortunately I did have the original 4V iron heads reworked by the (good) machine shop - though at a staggering cost. So those go back on and we'll see how it goes.

And this all started with a backwards head gasket.

Attachments

You are stating a new issue here that (I have to review your previous posts) I haven't heard before.

Pistons hitting the heads are caused by to high of a piston height. From memory, you need a minimum of .020" clearance between the top of the piston and the cylinder head surface.

Sure, that gets checked with clay and then adjusted with head gasket thicknesses. There is a selection of head gaskets available that will fix the issue.

The only "problem" with thickening the head gasket is you are reducing the nominal compression ratio.

Unless you are building an all out race engine, that's not an issue.

You are at most dropping the actual c/r .5.

All manufacturers use an "advertised" compression ratio and I know of NO engines that actually measure what they are advertised at.

An advertised (from Ford) 351 with a 10.5:1 will never measure out to that. It's more like 9.8:1. Now in the "olden days" right after Noah's Arch landed from the flood, we used "shim head gaskets" (thinner then stock) to raised the c/r about .5. That is provided you had the .020" clearance between the pistons and heads. That's how much the connecting rods stretch while running.

I just did this on my 347 with AFR heads. We had to shave the heads .025" to get the chambers to 54cc's and use a thin head gasket. That resulted in this case with a .023" clearance (few...close but clear!) and an actual measure 9.8:1 so that's good with pump premium.

I still have some clay. Want some? You can actually do it with a feeler gauge measuring how far down in the hole the piston is.

As soon as all the parts are not OEM, building an engine is not about stacking parts that "normally" should work together. You have to make a lot of dry assemblies and EVERYTHING to measure and check, it's tedious and it takes a lot of time but it is the only way not to have unpleasant surprises.

@jmardy posted:Thanks @panteradoug. Definitely a new issue and just discovered yesterday.

My original problem was misdiagnosed. It's been a learning experience for me - I guess I know just enough to be dangerous.

I didn't realize (or think to check) that the pistons were proud of the deck.

It's obvious to me now...

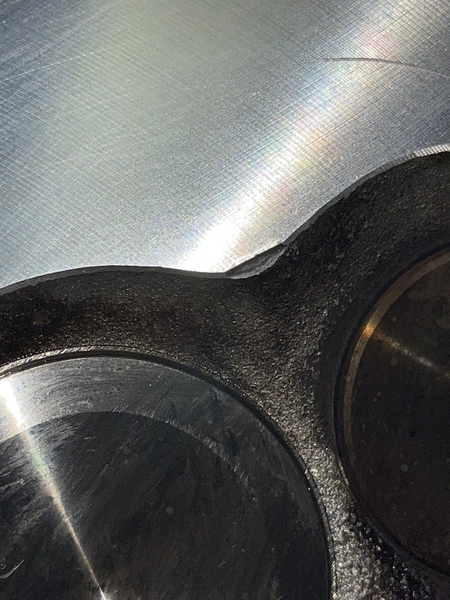

I was asked at one point if they were domed or flat and I said "flat", because to me, a domed piston to me looks like this:

Here is #5 at TDC:

The dome is designed to fit into the combustion chamber so that isn't normally relevant.

You take the depth measurement where the flat of the piston is at the edge in relation to the top of the bore. That can be measured with a feeler gauge. Now the pistons normally rock in the bore so the best place to do that if you can would be at the center line of the piston directly above the pin.

If you can't there then you can average the front and the back.

MJ will probably tell you to use a depth gauge with a dial indicator but that isn't necessary unless you positively have to be within .001" because everything is that close.

Looking at that pic it looks like you have zero clearance. Did that block get decked?

Even if the piston is above the block, all isn't lost there though. Even IF you are at plus (above the block) you can space the head up with a thicker head gasket. As long as it's less the .010". Stock, the gasket is probably .035 which would give you enough clearance. That's even a Felpro which is an inexpensive gasket.

This wasn't a mistake by the builder. He just set it up differently and you missed it when you changed the heads and gaskets.

Here's the thing though. You need to plastic gauge the rod bearings because it's possible you pounded them with the pistons hitting the heads. It's best to know that now rather then throw a rod because of crunched bearings.

Do all of the pistons have that mark on the edge of the point of the dome? Are any of the spark plug electrodes pushed closed? If they are and the plugs weren't indexed, those marks could be from the plug electrodes...maybe.

I'd expect any kind of a dome to have a fire slot machined in it for the spark plug. Look at the first picture you posted. See the notch for the plug?

Relax. This will all work out. You are just learning via the school of hard knocks and you'll be smarter AND wiser. ![]()

yes the rod bearings need to be changed minimum, the crank, rods & pistons inspected for damage. the pistons cocking in the bores may have distorted the cylinders as well, if not cracked them. sorry for your loss