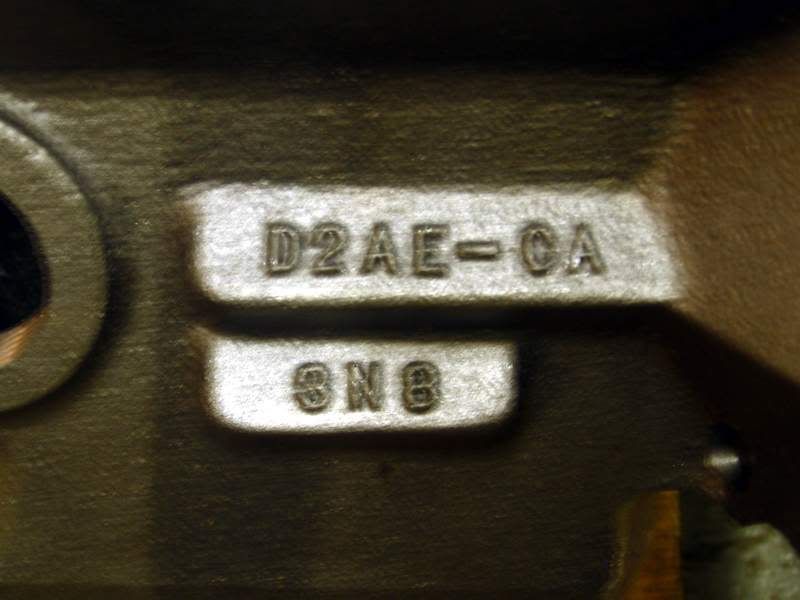

Quote: This is the block that was pictured in an earlier post. It has some casting issues. My friend Tom Hoover pulled the distributor out of a 1970 Cleveland that was in a wrecked car. He has had it for quite a while. Only has about 10k miles on it. We talked about using its parts to build this block up stock and see how it goes.

The issues I ran into were:

1. Casting was somehow made .100 too thick. I adjusted machining to make it only .080 heavy. Because the casting is too thick the distributor pocket is machined in deeper than designed.

2. I screwed up and forgot the oil galley boss metal in the valley, so you can see the weld put in before machining. It looks bad but doesn't leak. The pattern has been modified, and is ready for new castings.

3. Because I changed a drill diameter and angle, I nicked the passenger waterjacket when I drilled the front oil passage from the front main to the main oil galley. Block fill will fix it for our test build. This will not be an issue from here out. I added stock to the corner that was nicked.

4. I forgot to put the distributor hold down bolt boss in the cross-over water passage core box. What an idiot!!! I have already altered that. This block will be welded and fixed by hand. Pretty easy fix.

If anyone sees anything that raises red flags let me know. I'm anxious to get blocks to the guys waiting patiently for their product. The iron guys are starting to email me.

BTW splayed caps will be the norm in production.

Sorry for taking so long.

Tod