quote:

Originally posted by Aus Ford:

Given the 351c oil system cavitation issues would it not be benificial to use a oil with a viscosity toward the thinner end of the recommend ie: 10w40 rather than 20w50 ?

What are the thoughts out there about synthetic oils and their cavitation resistance ?

This is the first that I've heard about a cavitation issue.

The 20-50 recommendation came about as a Ford recommendation for the production Boss 351.

To me a 20 weight winter grade has always been questionable. I would take a guess and say that what the engineers wanted was the 50 weight and the only way available back then in multigrade was the 20-50.

Personally I feel with the availability of relatively inexpensive full synthetic like Mobil1, a 10-30 or 10-40 is fine for even racing use in this engine.

Oil weight really is going to be determined by the clearances that the engine has on the main bearings. The greater the clearances the thicker the viscosity of the oil needs to be.

I would think if you maintain 1.5 thousands clearances on those bearings a standard weight oil would be fine?

I never heard of the C oil pump having cavitation, or sucking air, at any rpm. These engines have been raced hard since the beginning of their introduction and the significant oiling modification for sustain high rpm is to restrict oil through the lifter galleries.

The designs of the Cleveland oil pumps is no different than any other engine. for racing purposes it is recommended to braze the oil pickup tube to the oil pump body but that's just to keep the tube from vibrating loose.

Another issue with racing them in NASCAR that was attributed to oiling issues was valve spring failure.

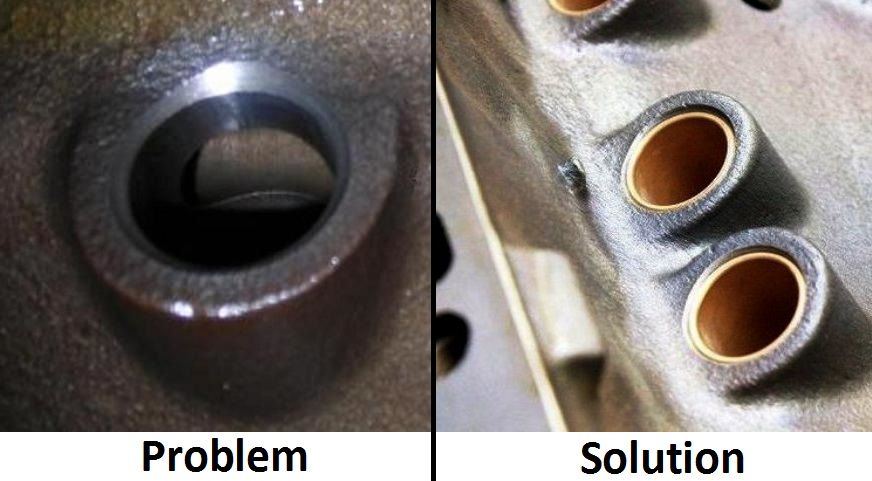

That was corrected in changing the oil drain back rate in the cylinder head. What was needed was to bathe the valve springs in oil to cool them to prevent failure.

You need to maintain about 1.5 to 2 inches of oil in the valve cover to cover the valve springs for cooling purposes FOR ENDURANCE TYPE RACING. Street cars do not need this.

That was done on the racing heads by changing the drain back holes in the heads. Also using the Ford Boss 302 drain back hose modification to the valve covers would be the opposite of what you want in a racing Cleveland.

I do not know if the T/A Boss 302's had this issue at all.