This is a photo album for the restoration of Pantera #2695. I started this project in October 2016 when I came across a car whose owners started its restoration about 20 years ago. They disassembled it, had it media blasted, and had lots of metal work done on the chassis including new wheel house metal, new rocker panels, new front valence, and anything else that had corrosion. They also built (but never fired) the original 351C engine into a solid lifter 377 cubic inch motor with high compression domed pistons, closed chamber D0AE heads, and heavy duty valve train. I substantially lowered the compression on the motor as you will see later in this photo album. They also accumulated many new parts including new glass, new suspension components, and other items that will be detailed later. When I bought this project I sold my 1971 Pantera that I owned and restored for about 10 years. The picture of its engine bay is my Avatar picture on this forum. The Pantera International forum and its amazing members have been instrumental and indispensable to my Pantera restoration successes.

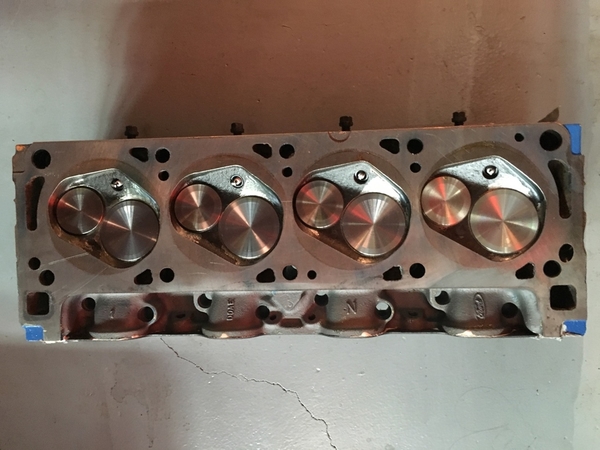

This is a photo album for the restoration of Pantera #2695. I started this project in October 2016 when I came across a car whose owners started its restoration about 20 years ago. They disassembled it, had it media blasted, and had lots of metal work done on the chassis including new wheel house metal, new rocker panels, new front valence, and anything else that had corrosion. They also built (but never fired) the original 351C engine into a solid lifter 377 cubic inch motor with high compression domed pistons, closed chamber D0AE heads, and heavy duty valve train. I substantially lowered the compression on the motor as you will see later in this photo album. They also accumulated many new parts including new glass, new suspension components, and other items that will be detailed later. When I bought this project I sold my 1971 Pantera that I owned and restored for about 10 years. The picture of its engine bay is my Avatar picture on this forum. The Pantera International forum and its amazing members have been instrumental and indispensable to my Pantera restoration successes.

Pictured is the chassis in its current form, getting ready for paint.

Replies sorted oldest to newest

Attachments

Attachments

Attachments

Here are some of the bondo tools utilized including a pneumatic gun and cartridges by 3M. The body shop up in Seattle completed about half the bondo and it was up to me to do the remainder. And the engine bay used a lot of bondo. The 3M gun became my new best friend for this effort. The electric sander pictured in the bottom left is used to flatten the bondo during its green state, intentionally clogging the sand paper. The air file (belt sander) gets into tight places.

Here are some of the bondo tools utilized including a pneumatic gun and cartridges by 3M. The body shop up in Seattle completed about half the bondo and it was up to me to do the remainder. And the engine bay used a lot of bondo. The 3M gun became my new best friend for this effort. The electric sander pictured in the bottom left is used to flatten the bondo during its green state, intentionally clogging the sand paper. The air file (belt sander) gets into tight places.

Attachments

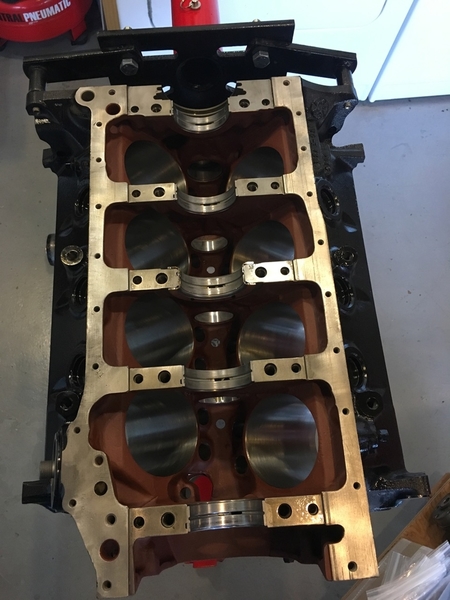

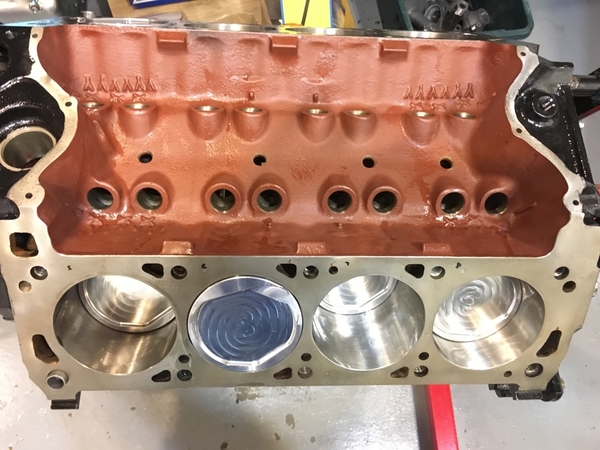

The stock 351C crankshaft was offset ground resulting in 377 cubic inches. Domed pistons were used and the result was very high compression that is not compatible with today's ordinary pump gas. Clay Smith Engineering (Mr. Horsepower) ordered new dished piston to reduce the compression. The dome of pistons that came with the car were the inverse of the dish that you see here.

Attachments

Attachments

Attachments

Attachments

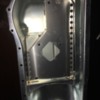

9 quart oil pan for Pantera by Kevco. Clay Smith Engineering blue printed the high volume oil pump for the engine to this pan.

Attachments

Engine on a test stand in the garage. It survived the initial startup and cam break in. What a relief. I changed the oil and filter after about 30 minutes. It was run for a total of about 4 hours during which ignition timing and manifold vacuum at idle were fine tuned.

Attachments

Attachments

Rear carrier. It was powder coated blue when I got it, along with all of the control arms and hub component. I had it all stripped to bare metal and then powder coated all pieces gun metal grey using the setup in my garage. The powder coating was relatively easy because once the parts where stripped they were back to a sand blasted finish.

Attachments

Attachments

Attachments

Are you not going to fit the "Double" bearing mod in the rear hubs though, It would be a good time to do so.

Its also nice to hear that bondo was needed on your car too, When I bare metalled my car body for paint I was amazed at the bondo used by what must have been the factory!

keep the pics coming (wish I could do that) they are an inspiration to other DTPantera owners