I just installed my new adjustable shocks from Wilkinson. I barley have any preload on the springs and they seem to be stiff as a board to the touch

just like my stock shocks. During the R&R took care of my squeaky bushings. I'm measuring the ride height as seen in the pics. The front is at 25" and the rear is 28 and some change. I would think it would look a bit stink buggish but it doesn't. I'm running 235/40-17 and 315/35-17 tires. My toe is way off, how could this be when I didn't monkey with it? I bought one of those 15 dollar camber tools to get the camber in the ball park for the 5 mile trip to the lineament shop, so guess it matters not. Any who, anyone care to put their 2 cents in on the ride height??

just like my stock shocks. During the R&R took care of my squeaky bushings. I'm measuring the ride height as seen in the pics. The front is at 25" and the rear is 28 and some change. I would think it would look a bit stink buggish but it doesn't. I'm running 235/40-17 and 315/35-17 tires. My toe is way off, how could this be when I didn't monkey with it? I bought one of those 15 dollar camber tools to get the camber in the ball park for the 5 mile trip to the lineament shop, so guess it matters not. Any who, anyone care to put their 2 cents in on the ride height??

Replies sorted oldest to newest

You need to drive it around the block a few times to make the shocks take a set.

IF your toe is way off at this ride height (toed out) then you need some bump steer help.

Check to see if you have the 10mm shims under the steering rack. That was the factory "fix" for the toe out at full upper travel.

I don't think that you can entirely eliminate toe change but the new spings and shocks most likely will not permit full up and down travel so that will reduce toe out changes.

3/16 to 1/4" TOTAL toe in at normal ride height is a good number.

The top of your fender openings should be even with the top of your tires. Keep driving around the block until the suspension settles there.

Wilkinson should have given you a good starting height for the shocks. He should know better if he didn't. The problem with him is he isn't a mechanic at all. You'd be better off with Chris at SAC Restorations. They actually can pre-set this stuff from their own car and experience.

Agreed on driving it around the block to get t it to settle, but looks like you are ready for some off road 4x4! How far up the shock body do you have the spring perch set? What shocks does Wilkinson sell and what are the compressed and uncompressed lengths? What spring rates did he supply?

You'll probably need to go with zero preload and wind the springs down on the perch to drop the height, then to avoid the springs coming unseated over potholes etc. you'll want some helper springs to take up the slack. Some vendors suggest to zip tie the spring to the upper perch, but that's a half assed solution IMO.

The toe changed because your ride height has changed significantly, did you measure the ride height with the old shocks to see where it sat, so you could target that with the new shocks?

Of coarse I didn't measure the height of the old shocks. The springs are 400 and 450.

Stock shock length is to long using a modern shock with the lower ride height everyone runs. 400 for the front is also to stiff. We have sold hundreds of shocks and have dialed in the perfect shock length and spring rate to illuminate spring problems like what you are describing.

Donny, now that the shocks are on the car you can use the spanners that came with the shocks to turn the spring seat rings and lower the car to your desired ride height. When you installed the shocks, you likely had the rings snugged up to the springs to prevent them from moving around.

You need some preload on the springs or they will unseat if the shocks become fully extended. If you want to go lower, you need different springs, shocks or, as Julian suggested, helper springs and spring guides.

Also, the spring rates strike me as a bit odd. The springs support the weight of the car, so the rates should reflect the normal F/R weight distribution. You shouldn't be using springs to tune the ride firmness or handling characteristics. That's the job of the shock absorbers.

It looks like QA1 has a solution to fill the gap if the car is lowered:

https://www.summitracing.com/p...BEAQYBiABEgLQ1PD_BwE

If you fill the gap, the ride height will raise by the same amount. The problem is the shock is TOO LONG.

Helper springs will help or the other band aid solutions may work. But the real problem is the shock is to long for the ride height desired.

Agreed. The spacer does nothing to solve the gap problem. Thanks for pointing that out.

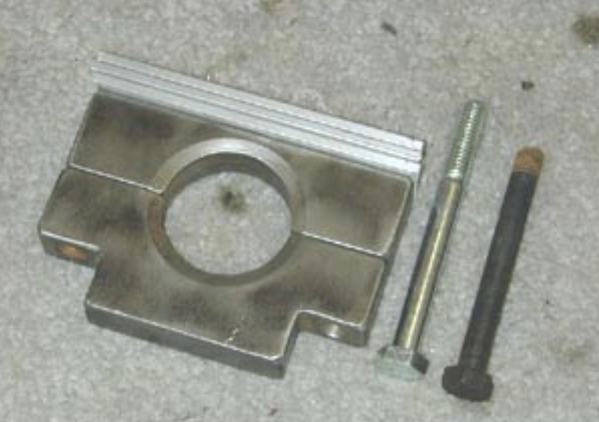

The over all length of the front shocks are a 1" shorter than the stock shocks and the rears are .2" longer than the stock ones. I have another question, My car is a early 71 and from what Steve told me ford didn't put shims in or on the steering rack until 72 to help with bump steer. Steve said to make shims 1/4" to 3/8". It looks like this will require relocating the steering braket and drilling four new holes. Tell me if I'm on acid or not. Here are the pics.

Attachments

Spring rates and wheel (spring) rates are different. Wheel rate takes into account the suspension geometry. The length of the A-arm from the inner mounts to the shock mount, the length from the shock mount to the tire contact patch and the inclination of the shock along with the spring rate gives you the wheel rate. There are wheel rate calculators on the internet. Spring rates are determined by vehicle weight, suspension geometry and dynamic and areo loads. Shocks control everything. Shocks are a lengthy topic for another day.

For our race cars shock tuning was 75% to 80% of suspension adjustments.

Ideally you do not want that gap. I have not done the math for stock Pantera A-arms and wheel widths but 400 pounds seems a little high. zr1 is correct in saying your shocks are probably too long. Keep in mind that you can get 400 Lb springs that are 10 inches long and 400 Lb springs that are 14 inches long and practically any other length. I suspect your spring/shock package is not correct for the car.

Unless EVERYTHING is stock you must first establish the ride height that you want to live with and work from there. Them measure the distance from shock mount to mount. Then do all the math for the correct spring rate. Then determine the max bump and droop to determine the shock length. Then get the shocks valved accordingly. That will get you in the ball park

OR

Call zr1 for the correct spring/shock package.

Just my 2 cents

I think I have the right ride height in the front, top of the tire to the top of the fender well with the shock loaded like Doug said. Steve said he has sold this shock and spring combo forever and that they are plug and play and tend to believe what he says due to his experience plus, I'm stuck with these shocks because I can't afford to be the Imelda Marcos of shock absorbers with 2,000 sets in my closet. It's best to have the steering rack level as possible, correct? In order to shim the steering rack down, I will need to relocate the bracket, right? It looks like someone has already drill holes in the bracket a long time ago but not the frame. The way I see it it will require one extra hole in the bracket and one in the frame on both sides. Has anyone have a pic of this procedure? It looks like the bracket serves two purposes, adding strength and rigidity to the frame and a extra attachment point for the rack. It's OK to say, you don't no WTF your doing or slap me threw the computer, I can take it.

That isn’t the rack mount you’re talking about, it’s a reinforcement. Look at Larry’s posting above. That’s the rack mount and there’s 2 of them.

Donny - you bought the shocks from Wilkinson right? I'm confused as to why he would not know the proper components for Panteras???

Donny, I would see if you can return the shocks and call zr1 for his set-up. That is what I did. For Bump steer you can also change out the tie-rods and add Heim joints and an extension. pm me and I can give you more information. No mods needed.

You don't re-drill the bracket. Look at the picture of the two piece bracket posted. On my car I did need to shave it, clip one of the corners to get it to clear of the battery box after being shimmed down. It's very tight in there.

In my case I had to switch to Allen socket screws on the close side. I wasn't able able to get a socket on a hex bolt because of the battery box ? There isn't enough room for it.

Check your ground clearance in the front, under the radiator support. If you can make a fist and slide it under, you're ok. If you can't, you're too low. You will wind up tearing out the sheetmetal or even the radiator support bottom on a curb or manhole AND even so, you will now need to be more aware of road obstructions wherever you go from now on.

Whatever you do, don't let a numb nuts, even a valet drive the car for even ten feet UNLESS you are prepared for fifty to a hundred thousand dollars worth of body and chassis damages.

1)-First Rule of suspension modification: EVERYTHING YOU TOUCH IN THE SUSPENSION AFFECTS WHEEL ALIGNMENT. Expect to play with all aspects of front & rear wheel alignment regularly if you continue to perfect your Pantera.

2)- factory bump-steer spacers (mid-'72-L model onward) are the metric equivalent of 5/16" thick but every 50-yr old Pantera will vary a little in what they really need.

3)- The rack steering rods should be parallel to the ground. Rack body alignment is not critical. Its easiest to adjust the rods for alignment where they attach to the steering arms. This is most easily done by replacing stock tie-rod ends with 1/2-20 SAE thread Heim joints with Ford-taper end studs, in unaltered steering arms. By coincidence, SAE thread Heims will screw onto stock metric thread steering rods with no alteration needed.

4) Stock suspension spring strengths were something like 200 lbs/inch front & 220 lbs rear. You have a semi-race spring setup, not a comfort setup. Springs are available everywhere in 10 pound-inch variations. Select spring lengths to fit your shocks.

5)- Adjustable shocks should be set for lighter damping at the front & heavier at the rear due to about 60% of the Pantera's weight being in back. The shock's bump-rubbers should be blunt-ended in front for 1/2" more travel & conical rubbers in back for less expected travel. .If yours are reversed, swap them.

6)- when using hook-spanners to adjust spring seat height, its easier if you decide what you need as an adjustment and jack up that wheel to take the weight off it. Do NOT oil the threads to make adjustment easier; it attracts dirt and road grime.

7)- Some adjustable seat-shocks have allen setscrews to lock adjustments, so slack them off before you attempt to adjust height or you can tear up the shock threads..

That should keep you busy for awhile, my friend. There are far more things possible to adjust (caster & camber, anyone?) but you have a nice start. Remember, ALL the above will change wheel alignment so the more changes you do at once, the less times you'll need to get a pro realign.

Boss. What size tappered pin does the Pantera use? I'm going to order the parts for this mod. I like the idea.

The rod ends would be female, correct?

You are wise Boss Wrench.

If you’re replacing your tie rods with Heim joints, make sure they’re Teflon lined and buy high quality, high strength items. I recommend Aurora. This is one place where you don’t want to go cheap!

We're talking about something similar to this, correct?

https://allstarperformance.com...ge?q=ball+joint+stud

-OR-

https://www.speedwaymotors.com...ud-to-Heim,3333.html

-OR-

Its a 7 degree taper, known as 'Ford Taper. Sold by Speedway Motors and others for dirt track racing, Ford (and Chrysler) ball joints are also 7 degree taper. I made mine from old ball joints and a lathe:straight stud on one end, tapered stud on the other so the steering arm need not be drilled out.

Mr Paschetto, that Speedway stud is it exactly. I see the price has doubled since I added them 10 yrs ago. To level the steering rods for bump-steer adjustment, once you have the studs, one only needs spacer-washers and a carpenters level.

Yes- the heims are female thread and screw on by hand, with a jam nut. They retain stock toe-in adjustment capability. I add heim-joint seals for some weather protection. They're pairs of conical neoprene washers that cover the ball on both sides. Not as elaborate as the full rubber jackets like on Mangusta suspension, but adequate. I think I got mine from Pegasus Auto Racing in Wisconsin. They specialize in formula car parts.

Thanks but not so much wise as poor and trained as an engineer. My whole reason for all the suspension mods was to make the car safer for my wife to drive anywhere, any time.

Boss, do you approve of the CJ pony parts kit? I like it cause it's here in my neck of the woods and available.

haven't ever used them- sorry

@Donny Dotson posted:Boss, do you approve of the CJ pony parts kit? I like it cause it's here in my neck of the woods and available.

He is not particularly known for selling the highest quality parts. I looked at the kit. He is not spec'ing things like 4130 chrome molly on the stud or the rating of the rod ends.

It looks to me the CJ pony stud doesn't have much adjust ability because of the shoulder. It seems you would need to pull it up as far as possible to get the rack level. Has anybody used a or does any vendor offer a stud and heim kit?

The CJ Pony Parts stud is the best design of the three mentioned. With the other two, if you adjust the Heim joint away from the steering arm, the Heim will be in direct contact with a threaded portion of the stud. The CJ stud uses spacers to move the Heim further up the stud, so it’s never in contact with threads. If you want the Heim to be in its lowest position, the spacer sits above it. Unfortunately, the Heim joint and adapter appear to be too long for a Pantera application.

I'm such a retard , I've been under this car and looked at the ball joint 7000 times and had it pictured in my mind that the TR end was below the control arm. Part numbers or a vendor would be appreciated, I need to go ream on this car ASAP before they outlaw gasoline and the world ends.

You can get spacers separately. There are no premade kits that will fit the Pantera. You need to get two 1/2"-20 female premium chrome molly rod ends with 5/8" bore and an assortment of chrome molly spacers.

All of the "kits" are using male rod ends and threaded tubing. That makes the assembly too long to use in the Pantera.

So, use the speedway studs and source the heims from Pegasus or Aroura? I have no experience with heim joints.

First call Maximum Motorsports and see if you can buy their Mustang kit without the Heims and adapters.

Donny, Have you checked by measurement to see if your car has excessive bump steer? I’m not far enough along on my car to check yet but I know from experience designing suspensions that steering arms being parallel to the ground doesn’t automatically equate to no bump steer. Maybe it does for P-cars at a specific ride height. It’s fairly easy to check and should be checked anyway.

@racecarmike posted:Donny, Have you checked by measurement to see if your car has excessive bump steer? I’m not far enough along on my car to check yet but I know from experience designing suspensions that steering arms being parallel to the ground doesn’t automatically equate to no bump steer. Maybe it does for P-cars at a specific ride height. It’s fairly easy to check and should be checked anyway.

The question has been asked before, "what is excessive bump steer"? We are looking for a number, not a description of what it is. Zero would be perfect but probably not possible, so what is an acceptable number?

I've looked as much as I can and there is no one that I know of that is quoting an actual number. They just speak in generalities.

IF someone is going to all of this work, and measuring bump steer is labor intensive, don't do it before shocks and springs, do it after.

There are a few race shops that deal in suspension components. Pegasus is just one of them and a good source, but Davids concern of using an adjusting nut instead of solid spacers is credible, but you can get the spacers separately also so you can use the Speedway studs, just plan on spacers as well.

I might suggest also that if you are going to go to this extent then get the sphere ball anti-sway bar ends and do them at the same time.

Mike is correct when he said that this is a lot of effort to go to, without really knowing if you have a bump steer issue. You should start off with the rack spacers, then go from there.

Also, my issue with the Speedway stud has nothing to do with spacers vs nuts to locate the rod end. If you do indeed need to move the rod end higher on the stud, do you really want it acting on a threaded portion? Eventually, the threads will be crushed and the result will be slop in the steering.

As an aside, years ago, Gary Walker (Comp2) told me the Pantera’s steering rack is too long to ever have zero bump steer.

@davidnunn posted:Mike is correct when he said that this is a lot of effort to go to, without really knowing if you have a bump steer issue. You should start off with the rack spacers, then go from there.

Also, my issue with the Speedway stud has nothing to do with spacers vs nuts to locate the rod end. If you do indeed need to move the rod end higher on the stud, do you really want it acting on a threaded portion? Eventually, the threads will be crushed and the result will be slop in the steering.

As an aside, years ago, Gary Walker (Comp2) told me the Pantera’s steering rack is too long to ever have zero bump steer.

I have no argument with anyone here. Maybe we can persuade Bosswrench to post some pictures or details of the stud that works best?

I can't say that the rod end is going to need to be raised to the threaded portion of the stud so only someone who has actually done this could answer this.

I'm sure that more then one person has but I only have the Boss to ask for that information.

Measuring the toe in/toe out changes during suspension changes in the front is also cumbersome to say the least AND changing spring and shock rates may make the changes at maximum travel up/down almost irrelevant?

David. If the rod end needs to possibly be shimmed up with spacers, how can it be kept off of the threads? That isn't possible without a specifically machined stud, but that would remove the possibility of adjustment, up or down?

I'll see what I can do, when the snow melts. Maybe revisit those old articles in the Newsletter. The biggest source of funny steering problems seem to occur when you change the front ride height- even removing the front coil-over spring spacers will do it. The rack moves up/down with the body relative to the ground while the rod ends are fixed in height off the ground by the wheel and tire sizes.

Rack spacers do two things because that surface they bolt to on the front of the trunk floor is at about a 45 degree angle. So rack-spacers on a front-steer Pantera move the rack forward which changes bump-steer and Ackermann-toe, while they also move the rack down, which also modifies bump-steer. Hard to keep all this stuff straight in one's mind unless your name is Dallara.... And of course, street guys may not even notice.

Changing shocks has morphed into a major suspension geometry project!!

Interesting discussion!