The advantage with these is that when the deck lid is closed, there is ZERO pressure on the decklid. That's a big plus.

The other thing with them is that they work off of a dual frequency "remote". One frequency is for the door locks, the other opens the rear deck/trunk.

What's also neat about this setup is 1) it's very easy to install 2) the cylinders look just like the original Detomaso units with the accordian boots and all and they leave the original trunk lock in place.

The compressor is here, the hardware is here, I'm just waiting for the cylinders which are currently on back order from the manufacturer.

This is all ok since it is letting me catch up on all the yard work caused by this last nasty winter. It did a lot of little damage that went unnoticed because everything was buried in ice and snow for so long.

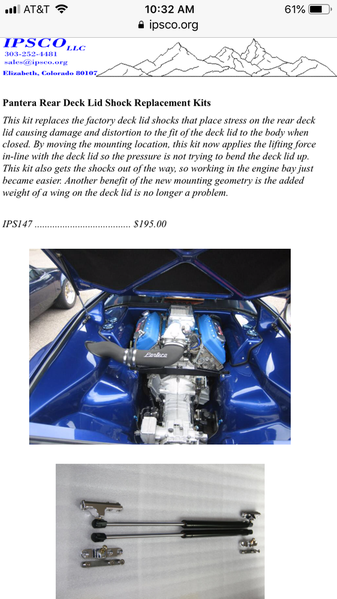

In the meantime, I need to replace the two Sachs struts that are in there now.

This is all ok at the moment. If it goes into June I'll start to get a little impatient with waiting.