quote:

Originally posted by 4NHOTROD:

Wing or no wing? Can you get Napa parts there? Will

Have currently a teeny weeny "wing", but that's on the long term subject to change (I have the intention to get rid of the wing).

I'm not sure whether the current (dead) struts are still the originals, but they are huge, which made the parts dealers I did visit think it were suspension shocks... Over time someone did paint them, so can't see any partnumber or thelike on them.

I read the Wilkinsons are good, later on they are not, I read the originals (the 18126A's) are good, later on they are not, PIM sells them, etc...

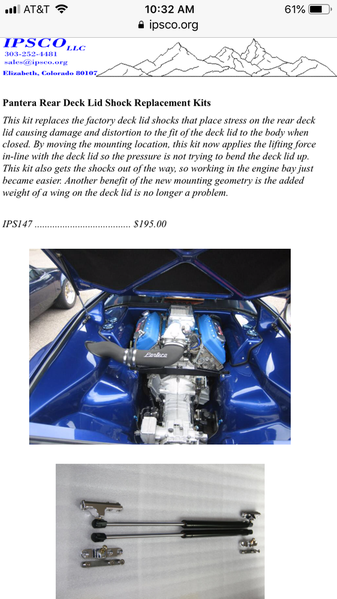

I don't want to go for the IPSCO modification set for sure - don't like to drill extra holes, and see the original attachement points being unused, nor do I have plans to go for 180° headers.

NAPA will be a no go over here, but BOGE does indeed ring a bell... I could wait until I'm in the US again (which I was only a couple of weeks ago, but too little time to get into buying car parts), and check out NAPA or Autozone, but I'd like to have new struts, the sooner the better...

Now I have an idea of what pressure needed, it might make the search easier too though.