I drove the car for about 80 miles today and it came back with a new and unhealthy sound near the back/top of the engine. I removed both belts from the pulleys in front and the sound persisted. I used the stethoscope and the sound seemed to be coming from under the intake manifold. When the motor is rev'd the sound is drowned out and does not increase in intensity. I am guessing it is something in the valve train. A video that somewhat captures the noise is below. Any ideas? Thank you.

Replies sorted oldest to newest

Hi Steve -

Just to get calibrated….

Is this the same motor?

https://pantera.infopop.cc/topic/23427805051325857

To follow along with the future posting, maybe you should get a magnetic drain plug?

Rocky

Have you checked for any metal in the oil?

In the morning I will pull the drain plug (and keep my thumb on the drain hole) and see if it is magnetic. The pan is Dennis Quella's 9 quart aluminum pan. If it is not magnetic I will put the plug back in and find one that is magnetic. I don't want to loose oil that could help isolate the problem.

Rocky, yes this is the same motor in the thread you mentioned above. That problem has gone into hibernation. This current problem make a sound that is completely different and is at the other end of the motor.

Sure sounds like a valve train issue. Maybe a bad lifter, but of course that's coming from an office chair diagnosis.

...Just started after a drive!?...Sounds like a Push-Rod Chaffing against the 'Guide Plate'! Or 'It's' bore in the Head, most common when using 3/8" Push Rods. Also could be a Rocker Arm chaffing against the 'Oil Filler Hole' BAFFLE. Or, the Roller of a rocker is Dry*, Seized and is chaffing the Valve Stem. The rhythm Does Increase when the engine is revved. Can't Explain Why it started 'all of a sudden'.

* Yes, could be a bad Lifter Not Pumping Oil through the Hollow Push Rod, causing the Rocker Arm contact point to Rod, to run Dry, and also, the Needle Bearing Pins.

Run the Engine with the Valve Covers Off! And be prepared for the MESS! There are 'Clips' that Redirect the Oil 'Squirt', Back, so you may do this Inspection. It's the Only way to Know for Sure! Other than tearing ever thing down...searching for a Shiny/Polished, Spot, that's Not suppose to be there!.

Best of Luck in Your search!

MJ

If you can find an old (sheet metal) valve cover, you can cut the top off….

That would cut down on the mess!

But don’t cut up a historical Ford valve cover, of course!

I have a valve cover for setting lifter preload with the engine running. A picture of it is below. It is very crude but it keeps most of the oil from coming out. The other trick is to turn the idle as low as it can go.

Attachments

I pulled the drain plug from the oil pan and it is magnetic. There was not any trace of metal shavings or metal debris.

I ran the motor and listened with the stethoscope near the valve covers and intake manifold. The sound seemed to be coming from the valve train for cylinder #4.

Next I pulled the valve cover and inspected preload (pushed and twisted the rockers) and found that the lifter for the intake valve for cylinder #4 was mushy. I have seen this problem before and in that episode two of the lifters had debris (oil filter element?) in the intake port that prevented the lifters from pumping up. I ended up replacing the full set of roller lifters. My next step is to pull in the intake and fix or replace the problematic lifter.

Attachments

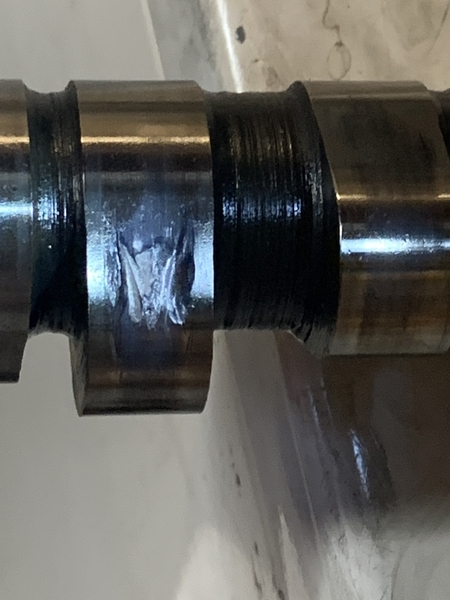

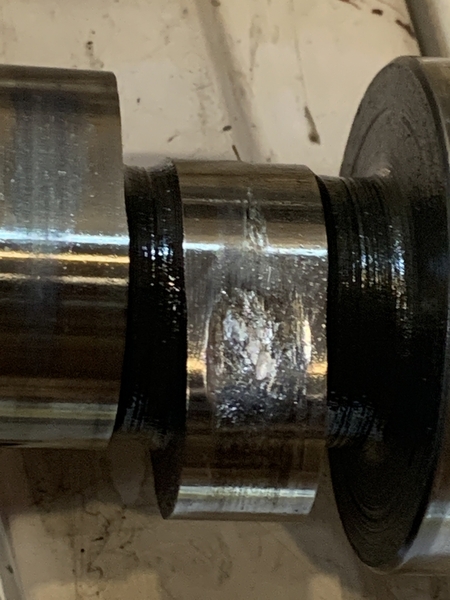

I pulled the suspect lifter and it is damaged. Something galled the roller as you can see in the photos below. I put a camera down the lifter bore and it looks like the cam lobe is also damaged. It looks like a new cam is needed.

The lifter next to it is also damaged on the side of the roller (its surface is OK).

The lifters on cylinder #3 look perfect.

Attachments

I pulled the oil pan and found a broken part in the sump. I do not know what it is. It has a gouge in it. Does anyone recognize it?

All of the lifters are perfect except for cylinder #4. There was no other debris in the sump and that means the other half of the mystery part is still in the motor.

Attachments

Thanks George and Larry. I think you both identified the part. However, it is not the root cause of my lifter damage because the flange on my distributor is in place and intact (photo is below). It looks like that cracked flange has been laying there for more than two decades.

My next step is to pull the cam and asses the damage to the lobes for cylinder #4 along with any collateral damage. And the precipitator of the problem has yet to be found.

Attachments

Yep, that's the part. My 72 Ranchero GT with a Cleveland had the same issue. Dist. gear broke off and took out the bottom of the distributor. All of the pieces were in the pan. Common on the 351C. Maybe a piece got sucked up and took out the lifter/rocker.

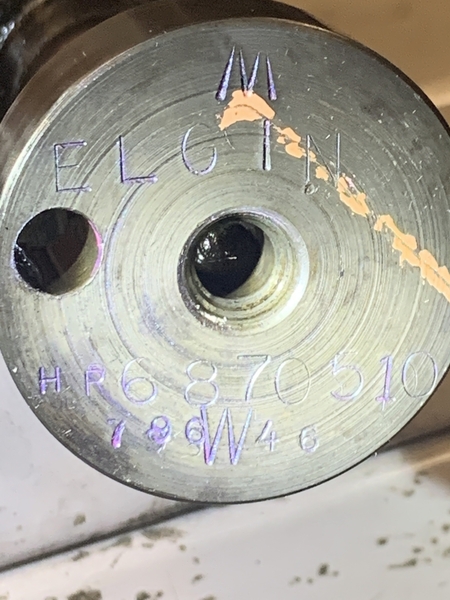

I pulled the cam and there is damage to the two lobes where the lifters were damaged. The rest of the cam looks good. The cam is by Elgin and is likely a custom grind. I will take it to Clay Smith Engineering tomorrow and maybe they can fix it. At this point I am thinking the pair of lifters got out of their dog bone retainer, rotated for a bit, and went back into the retainer. I plan to turn down my rev limiter (currently 6500) and cross my fingers that the problem does not recur. Here are photos of the cam stampings and damage to the two lobes.

Attachments

Steve - while this is a painful process of discovery for you it is greatly informative to the other members of the forum and your efforts in posting the investigation process and pictures are invaluable.

Much appreciation and hopefully a repair is achievable !

Thanks Percy.

I wrote to Dimitri Elgin and he interpreted my cam specs as you can see below. He saw the photos of the lobe damage and said I need a new cam. He recently sold his last blank to another Pantera owner in Northern California and said a new blank may be hard to find but he will try on Tuesday. He also said he made my cam in 1996.

cam specs:

Hyd roller

68x4=272 intale duration, 70.5x4= 282 exh duration

the 10=110 lobe centers

26-66 int, 71-31 exh seat timing

Lobe lift times rocker ratio = gross valve lift. (my rocker ratio is 1.75)