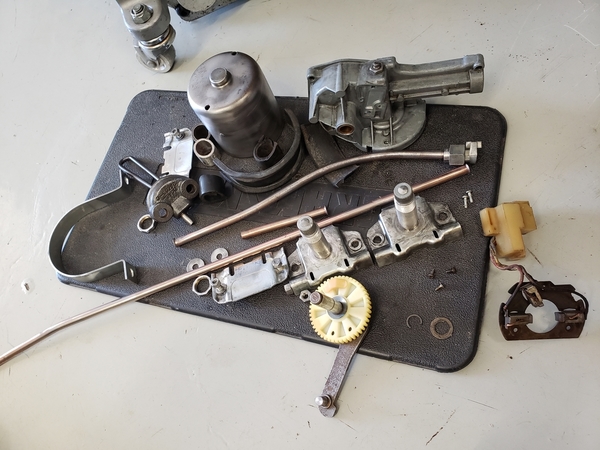

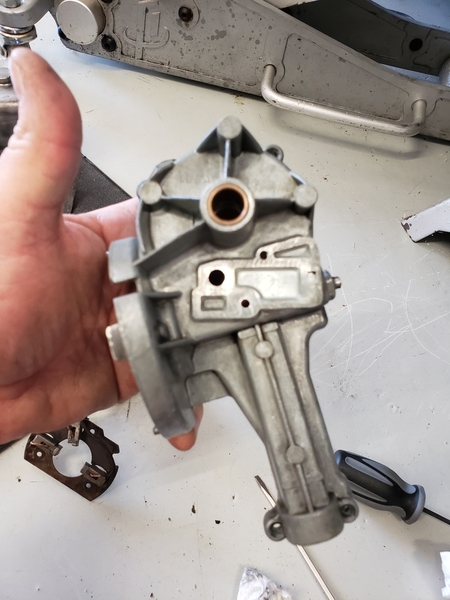

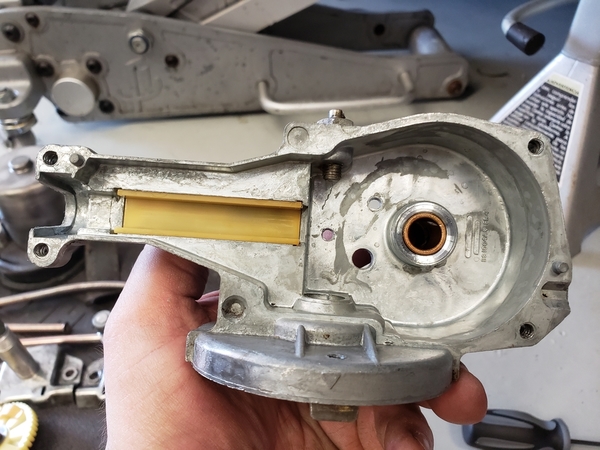

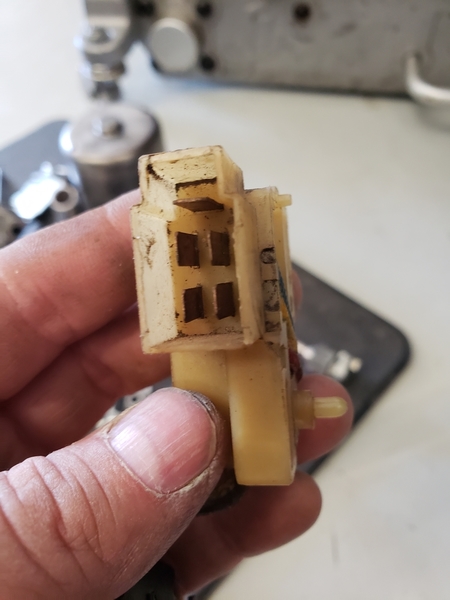

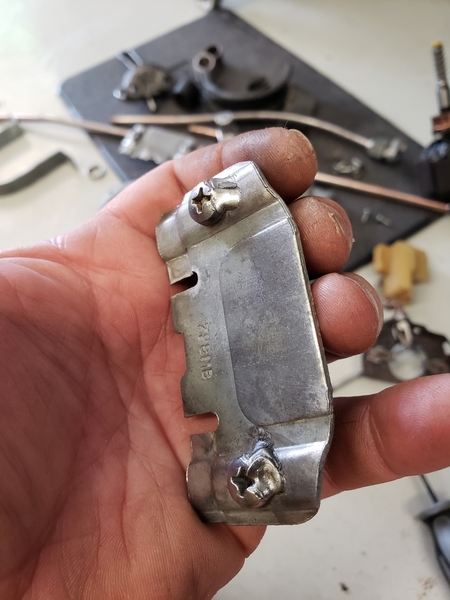

Here are some photos of a disassembled wiper system....

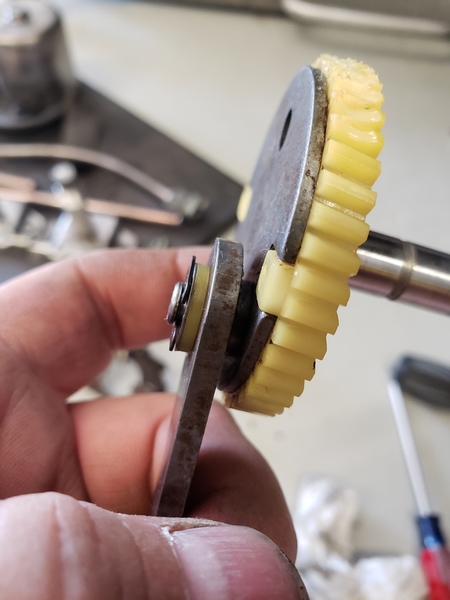

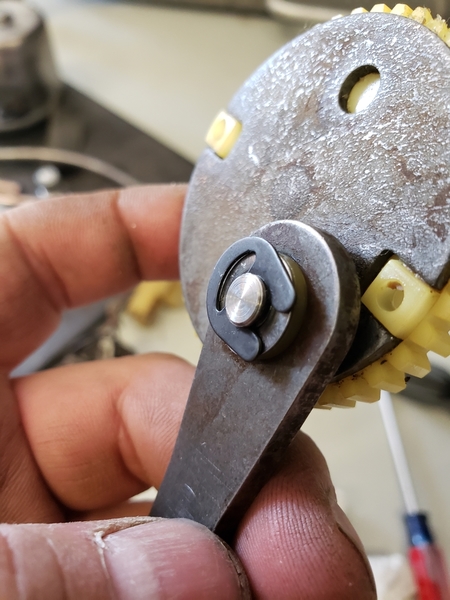

I think the purpose of the screw on top of the motor housing is to adjust the position of the rotor commutator in relation to the carbon brushes. I had the same prob with one of my radiator fan motor. If not adjusted correctly the brushes will rub (and wear out) against the small studs which contact the commutator fields with the windings.

perryh posted:

From a Lucas repair manual

Adjust armature end float

.

"To check armature end float when a non adjustable thrust screw is fitted perform the following operation.

Position a feeler gauge between armature shaft and thrust screw. Push armature towards cover.

End float should be 0.002-0.008 in.

In the unlikely event of adjustment being required end float may be increased by fitting shim washer/washers under thrust screw head or reduced by mounting thrust screw in lathe and removing metal from underside of head.

If a service replacement armature is fitted it should be supplied with an adjustable thrust screw and lock nut as a boxing sundry.

To adjust armature end float when an adjustable thm.st screw and lock nut is fitted perform the following operation.

Slacken lock nut.

Screw thrust screw in until resistance is felt. Screw thrust screw out quarter of a turn—maintain in this position and tighten lock nut.

Thus I would assume, the position of the cover bearing should set the commutator to brushes AND put the armature in the center of the stator. then the "screw" set the thrust end play

perryh posted:

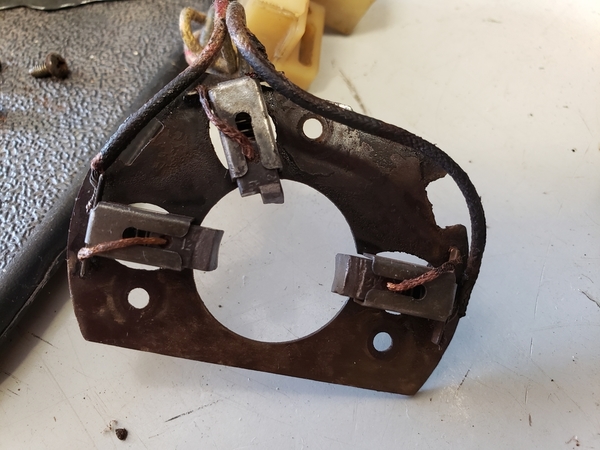

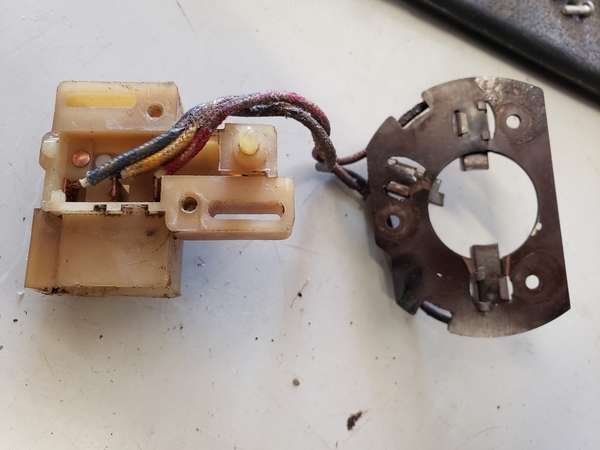

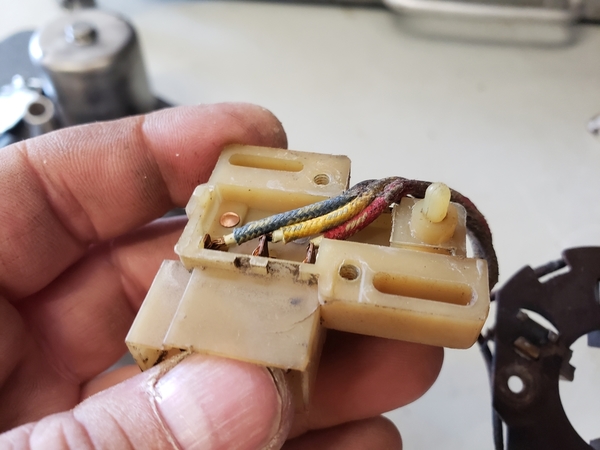

When I see the copper wiring on your electric motor anchor I think it's better to replace this .

The dark wiring must be copper colored, I think yours was too hot and burned .

maybe you can smells the burned wiring too.

Better is to replace the anchor , or maybe better the whole wipermotor by a (not expensive) aftermarket piece.

This is just my experience over the years.

Simon

I thought that too, but after I looked more closely, I don't think it burned.

I think that is 40 years of carbon dust from the brushes arcing and being deposited on the wires. The piece of fiber board that the brushes are mounted on was similarly coated. I could not get it off of the wires without risking removal of their insulation.

The motor does run. I partially reassembled it and tested it last night.

Warning and wisdom noted however. I will consider whether to heed it. I would not be so much worried about having to take it back apart (that's easy now that I know how). It is potentially setting my car on fire with some crappy old motor.

I am guessing this isn't right... ![]() unless loading the motor is needed to pull the rotor into a more electrically efficient position.

unless loading the motor is needed to pull the rotor into a more electrically efficient position.

It would have just kept going up, and I don't know how much current it was pulling. I'll stick an ammeter in series to see.

Edit - between 7 and 8 amps (I think in the high speed mode).