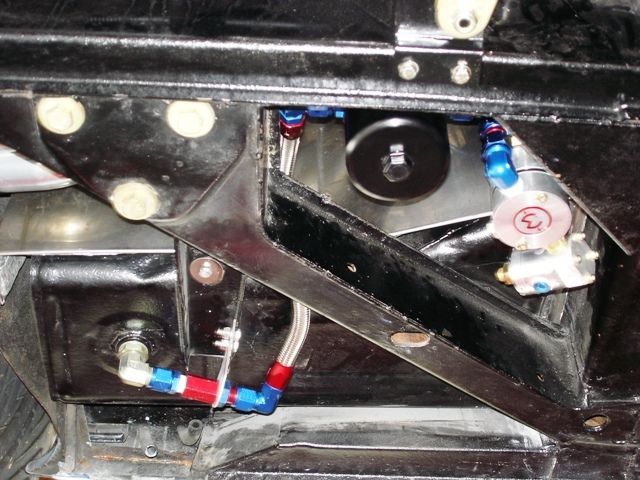

Using the bottom drain plug is just too low. There are only a couple of fittings that will fit the drain and they will hang down in harms way.

I think the way to do it IS to change the fuel pickup/sender unit to the current service combination one. You can get those from Wilkinson.

Then you can use the existing supply with the banjo fitting as the return line.

On the steel tanks, the pickup tubes are welded to the inside of the tanks and will eventually have a rust spot hole through.

That tube is not serviceable and you would need to go to the newer pickup anyway to fix the situation.

Some will say to put the fuel pump inside the tank, adapting a current in the tank pump BUT I think it is better to have it externally so the components are easily serviceable?

Then there are lots of electric fuel pumps you can select from.

As far as what to pick for an 8 stack, I like the "classic 8 stack" which is the one that looks like the Weber 48IDA's.

It hides all of the fuel rails and wiring so it looks just like Webers but there are other 8 stack systems available.

http://www.hotrod.com/how-to/e...ssic-fuel-injection/That company though keeps getting resold and at the moment I don't even know where you can get them OR EVEN WHAT THEY ARE CALLING THEMSELVES RIGHT NOW?

http://www.coroflot.com/thomas...assic-fuel-injectionIt will fit on one of the Hall Pantera Weber manifolds (4v vs. A3 port) which is a improved copy of the original Detomaso manifold which has problems with engineering details like the mounting flanges for the carbs being too thin.

Once you have the hardware, then all you need is a CPU and lots of people like the current FAST system.

The reality on tuning them is that apparently most are using them as a plug and play and running on the "as delivered" program successfully. So you could drive the car right away essentially without having to bring it to a tuner which you could do eventually.

The main drawback to all of this is the expense.

If you've got the bucks, go for it.

$1,000 for the manifold. $3,000 for the 8 stack. $2,500 for the cpu. Assorted hard ware, $350 for the pickup, wiring harness...unknown, fuel pump...pick one, fuel plumbing...start counting the fittings.

So maybe around $8,000?

I suppose a testament to how they all work is the lack of any being sold used? I can't think of even one that has come up for sale used within the last few YEARS! I've seen probably dozens of the systems running. The owners I have been able to speak to absolutely love them.

I'd be interested in a set if I could find them?