Wow did this thread bring back some memories. I re-read it over my morning coffee. I made a dozen or so systems and quickly learned every engine/system was a snowflake with its own unique requirements and nuances. The other thing I learned was 9/10 customers were not tuners and were buying the appearance of the system and had a zero probability of success without the assistance of a pro tuner, who will all have their own opinions, none of which will matter if they have never built and tuned IR EFI and Carbed systems. Those 9 customers expected me to virtually tune their unique combo from my keyboard and there’s just no way anyone could do that so I became very selective about who I would offer hardware and eventually lost interest.

Picking out some of the thread’s topics I think most relevant:

Hardware: Fit of throttle plates matters but most manufacturers have that covered. Can’t speak for the import stuff. The important thing is good linkage. It needs to open the throttle plates symmetrically and I preferred counter rotating banks for that reason. You also are well served with progressive linkage that opens the throttle plates more gradually for the first inch of pedal travel or it will run like WOT or nothing. Beyond that it just needs to be easily adjusted and stay put when tightened.

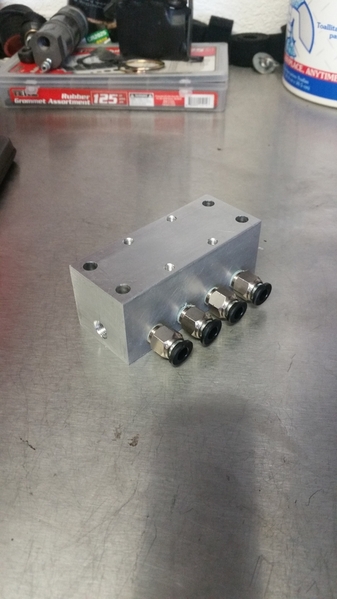

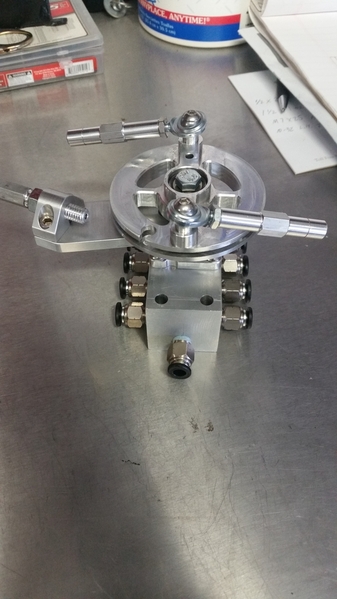

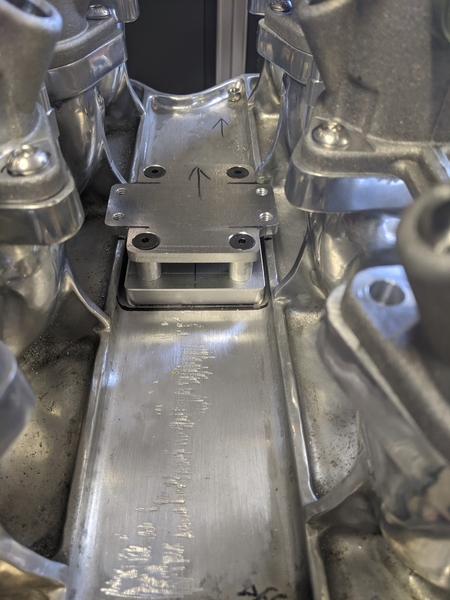

For control schemes, its already been said…..Alpha-N, Speed Density, or combos thereof. Mass Flow is a possibility but you need a complicated and very well sealed airbox and most of the people that are buying aesthetics wouldn’t consider it because it will obstruct the view of all the pretty IR hardware. For speed density, the one thing I always ask people is what do you think your trying to accomplish with the MAP signal? The short answer is a signal that’s a good proxy for engine load. In an IR system, it won’t mean a thing except down low because the instant you crack the throttle the vacuum signal goes to zip! Then the size of the vacuum plumbing and plenum is just lag. It’s true through trial and error you can find a combo of plumbing and plenum size that’s gives a more stable and representative signal. I suggest plumbing to a common vacuum junction block and then run a line to a remote plenum and vary the size of the remote. Now there is another aspect to communication ports. The overlap in cam profile will create a reversion pulse and it will stand a fuel plume that will confound tuning. This is worse in short runner systems. Even more so in non-EFI carbed systems because the boosters will add fuel no matter the direction of flow and can even soak filters and create a fire hazard on backfire.

Injector position: Yah in theory (and I love theory!) and very high states of tune it makes a difference but for a street car I’d tell you it doesn’t make a hill of beans difference. The fuel rails in the middle does look a little cleaner but makes accessing the linkage a lot more difficult. There are literally millions of street cars with the “unfavorable” injector position and they run just fine. Quella’s race car had the injectors on the outside of the runner and put down 750HP and was a beast. Same with Kirby Schrader’s GT40 albiet at more modest power level (Sorry Kirb)…..and for anybody that tells you that Weber IDAs are too small for 400CI and 600HP+ just go take a lap with Kirby’s Pantera track car or any engine Mike Trusty set up.

One thing about EFI is everything can be tuned, it just takes a lot of sensors and patience. The reality of that is everything that can be tuned must be tuned and that is one hell of a lot of work.

A couple other random thoughts:

I had my one of those Morrison intakes a long time ago. It was a work of art but I have never seen so many socket head cap screws in one place in my whole life and if they would have built very many I would have bought stock in Loctite. I actually still have a set of just the throttle plate assemblies.

DaveK, I have the aluminum version of the CF Panoz intake you posted. It is a TIG and metal forming masterpiece for C3H heads on an 8.2 block with staged/dual injectors. I’ll never use it and need to sell it someday but every time I take it out of the box I can’t bring myself to do it. I had two and sold the other. I was told they had problems with the CF versions failing and made the aluminum versions for replacements. I never confirmed that and the aluminum versions may have just been the development mules for the CF versions.

Happy tuning fellas. Kelly out!