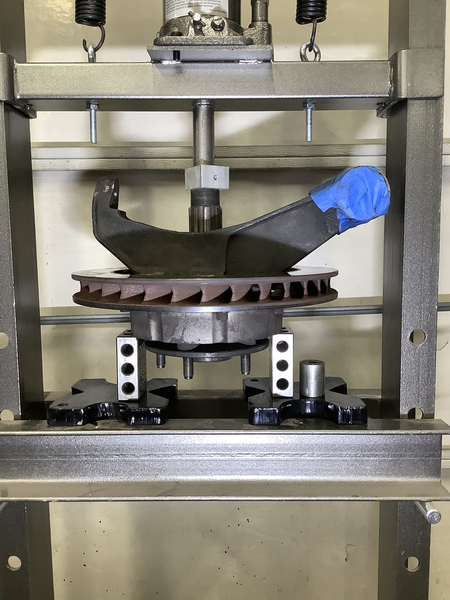

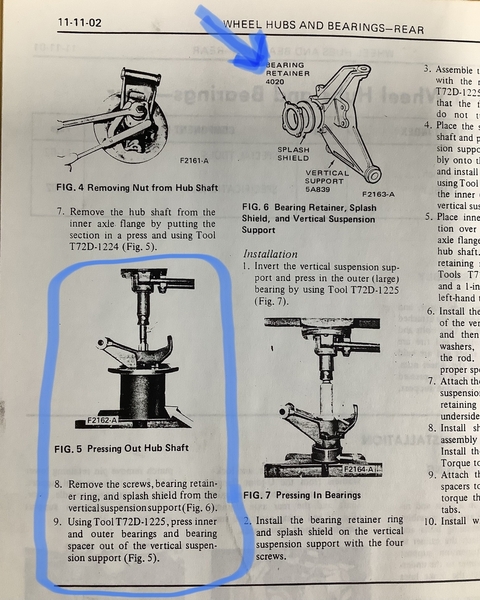

You are right to be concerned about pressing on the rotor(s). Some have broken them in two with a 10 ton press. About any kind of press stand-off will work; I've seen them of plastic or hard wood. Pressing each of the lug-nut studs out first vastly lessens the amount of force needed to push a stub axle out of an upright assembly. Do NOT hammer them out- they are high-carbon steel and will crack if hit even a little bit sideways!

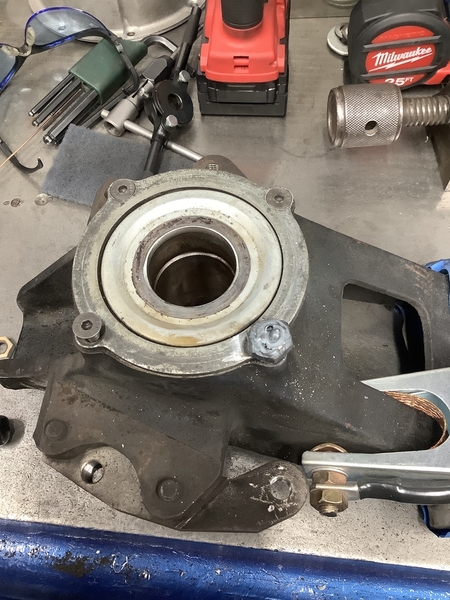

The retainer must be in place to press out the axle. Using too much pressure will distort the mild steel bearing retainer into a shallow cone, which then does not correctly hold the outer bearing in place on reassembly. Perceptive drivers will notice some rear steer effect and excess tire wear from even tiny amounts of rear stub-axle movement. Hammer the retainer down flat on a heavy piece of steel if it's cone-shaped or wavy.

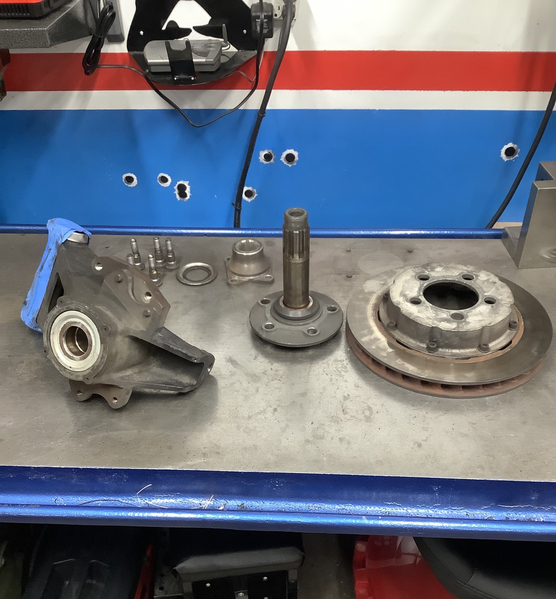

The real problem is, because of leverage the required clearances are very small. The axle shaft should be an interference fit of 0.0005"-0.0008" in the bearings and yes- all those zeros count. In most cases, the extremely hard bearings are fine but the relatively soft mild steel stub axle is either worn from spalling, or undersized. Find a shop that has a 5-decimal 1.5" micrometer, or rent one to check axle wear. ALL other methods of checking are little more than guessing.

Some stock axles and most aftermarket axles (of high strength 300-m steel) will be the correct interference-fit size. But I've heard of good looking stock axles that FELL OUT of new stock bearings. There are tolerances in everything so we must check.