No, but I did install an aluminum Girling clutch master with no separate reservoir, back in 1982. Still working fine but I did have to elongate the mounting holes in the Girling with a file, as they were a bit too wide. I also replaced the black plastic cap when it split at the threads. I used an aluminum cap by Pegasus-Racing.

Note the aluminum Girling with no translucent reservoir solves your problem of seeing "Black Stuff" in the reservoir. Since it was mentioned several times that it is probably either iron oxide, or carbon black commonly used in rubber parts, did you ever check your debris for magnetism? That would narrow it down to essentially one material.

I did - non-magnetic 3d particles at the bottom of the reservoir with the finer black particles remaining in suspension in the fluid. Garbage bore finish, cheap seal materials and improper clearances- pick one!!!! Time to move away from Pantera vendor parts!

I believe the ATE and ItaliaBrake units I found on the web are direct replacements. That includes the slave cylinder. I was hoping someone could provide the measurements for the MC so that I can verify with ATE.

@Rob Fridenberg posted:Has anyone found/tried a Wilwood clutch master that fits the Pantera?

I installed a Wilwood Clutch Master Kit from SACC Restorations in 2018. I later ran the excess braided line under the front trunk.

Attachments

@Rob Fridenberg - I have a brand-new SACC Restoration Wilwood Clutch Master Cylinder if you are interested in trying one. I had it installed, new used and then upgraded to a dual master cylinder configuration and got another Wilwood Clutch Master Cylinder in that set-up. SACC modified the mounting holes so it would use the Pantera mounting holes. PM me if you are interest. Larry

CNC was a firm located in San Diego that supplied Dennis Quella with his aluminum clutch master cylinders.

The OEM center to center clutch master studs are roughly 2 inches, but the standard spacing for the CNC master used by Dennis was 2 1/4”. Dennis arranged for a batch of them to be made with the necessary OEM spacing, but they were only available through him and not directly sold by CNC. You see a lot of these, or close cousins, on many Panteras. Shortly before CNC ceased operations I purchased a 3/4” master from them, made with a S&S sleeved bore.

The modification to the mounting holes by SACC is far from a precise, machining operation. I modified my SS master mounting holes very easily with just a good rattail metal file.

In short, just about any aftermarket three-quarter inch bore aluminum master can be easily modified to fit the OEM studs. A cast iron/steel mounting base would be more problematic, however.

And of course, one advantage to a aftermarket replacement is the ability to purchase from an established firm having a respectable track history of being able to deliver quality components……😉

Larry

Great insight Larry. I bought a CNC slave from Dennis. Has been perfect.

Appreciate the info on Wilwood masters - I assume the stroke specs are adequate for the Pantera set-up? Any performance issues using a long braided line?

I'm waiting on resolution from the vendor that provided my masters, but going with a Wilwood seems like a safe bet for the reasons that Larry mentioned.

No functional performance issues with the braided line. Once bled, the length of the line doesn't really matter. Although, the original braided line did spring a leak a couple of years ago for whatever reason. Shouldn't have, but it did. Those lines are rated at 3,000 psi. Replaced the line, and no problems since.

Just in case, I like to keep a spare of just about all the potential failure items. That way I can continue to drive throughout the cruise-in season here in lovely Ohio... ![]()

As I mentioned, I eventually pulled the hard line under the front trunk and routed the extra length of the braided line through the hole.

Attachments

Here is the Wilwood MC as shown above from their website. Bolt spacing is 2.25" which from a rough measurement of mine seems about correct? Price is $83 bucks. How could one go wrong on this.

With the link:

As Larry said above, you will have to elongate the mounting holes a little bit to match OEM bolt pattern.

While previously searching for clutch master info, I ran across where Bosswrench said that “...most aftermarket clutch masters mounting holes are 2.25” center-to-center, and the OEM Pantera clutch master is about 1.85"center-to-center".

Attachments

Great info on the Wilwood product! I assume the braided line is not part of the kit??

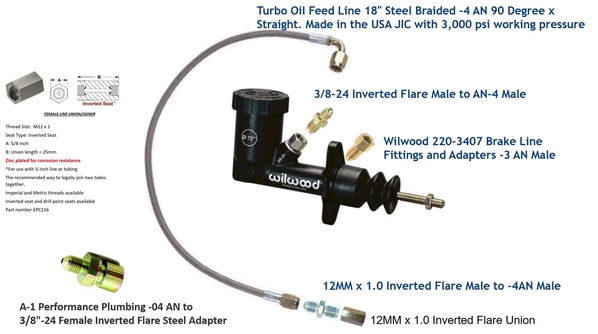

The braided line and all the adapters were part of the original plug-and-play SACC Restoration's kit, but that kit is no longer on the Web site for whatever reason. So, I put this info together for future reference...

Unless I'm misremembering, the A-1 Performance Adapter in the image is associated with the clutch system hardline.

Attachments

Ron - thanks for putting this together as this may be the best direction for master replacements for those that prefer reliability over originality.

The "original" clutch masters I was buying were blowing seals. At least the Wilwood masters can be rebuilt. Cheap enough that I keep a spare Wilwood clutch master and rebuild kit on hand so my Pantera is not parked and waiting for parts during the cruise-in season. Of course, connecting the thing under the dash is about the worst job on a Pantera and where bodies, heads, hands, and fingers do not belong...

I have to pull the seat for access. Can't contort like that anymore.

Ron - any reliability issues with the wilwood? How long have you been using it? Your spare comments make me nervous! Perhaps it is ptsd from the garbage repro parts??!!