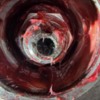

So, which would be better for bolting hub to rotor given I cannot find M8-1.25x28 partially threaded bolts in 10.9 or 12.9 grade

a) 4 bolts 'like the old bolts' that appear to be grade 8.8, M8-1.25x28, are partially threaded to 'match no threads in hub' (about 8mm), threaded to match the threads in rotor (about 20mm), and will take about 18ft lb of torque

or

b) 4 bolts that are grade 10.9 (or 12.9) , M8-1.25x28, are fully threaded bolts that 'don't match no threads in hub' (about 8mm), matches threads in rotor (about 20mm), and will take about 27 ft lb (or 31 ft lb) of torque.

Question is which makes for strong hub rotor assembly, matching the partially threaded old bolts that align with the bolt hole threading, or going with the 10.9 (or 12.9) stronger bolts that won't have bolt hole threading thru the 8mm of the hub?