While my planned debut of my most recent endeavors was to be at next week's Concorso Italiano, you my friends get a sneak peek.

While my planned debut of my most recent endeavors was to be at next week's Concorso Italiano, you my friends get a sneak peek.

Of course, I had done a lot of prior planning and measuring; cardboard templates using website measurements, staring and thinking - you guys know the drill. But once I finally took the leap and began, this was one of those projects that just kept growing. I just kept at it and solved whatever came up; couldn't just throw in the towel at that point. ![]()

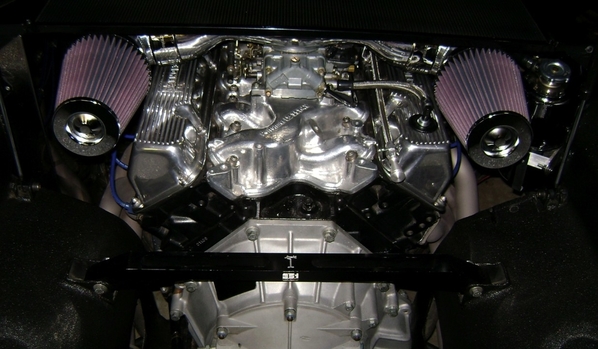

The air plenum is a Spectre product - part #98599. It is cast aluminum and easily fits under my stock screen; it sits directly on the carb flange and has about 1/2" top clearance.

Link to Spectre page: http://www.spectreperformance.com/#CATALOG.98599

I added two Spectre 4" diameter, 90 degree elbows and capped it off with two K&N cone filters.

In order for it to fit,I first needed to remove the stock engine oil dipstick tube. So I ordered a custom flexible, braided SS Lokar oil dipstick/tube unit. To get it installed meant opening the firewall cover and removal of the alternator. I bent the Lokar-supplied bracket for the rear-most mount, fabricated another valvecover mounted support bracket from strip aluminum, and held the front portion in place with an Adel clamp mounted to a fabricated bracket on the front of the cylinder head.

THEN, I had the coolant tanks to deal with. I drained the system first and tried Plan A. I initially figured I had to relocate the surge tank to a lower position to clear the filter, but that wound up not being so simple as it hit the header tubes just before it found air filter clearance. So, I fabricated a simple bracket to relocate both tanks into the overflow tank area. Had to remove the remains of the charcoal canister bracket, and then (because it was now just an ugly unused piece of metal) remove the stock surge tank mounting bracket, too. Of course the nice SS coolant tubes no longer headed to the surge tank fittings. So, both of the pipes had to be removed and then cut-trial fit-cut until they would work. I sourced some 45 degree hose elbows of molded silicone, cut down the hoses to proper lengths and put things back together.

While I was at it, I flipped the chromed dual-inlet fitting to the Holley, so the rubber fuel line is now up front by the distributor and out of sight instead of curving around the backside of the engine.

The ends of the filters just clear the luggage tub by about 1/2", the valve covers by about 1/4" and the engine screen by about 1/4".

A LOT more work than I had envisioned, but then.....isn't it always that way?

But at the end of it all, I am very pleased with the final look.

Larry