Hello

Hello

I have not posted here since 2008 when my first Pantera was done.

But now i have a new project.

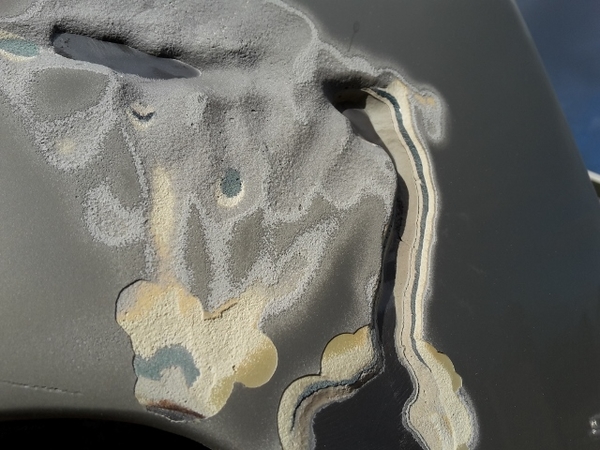

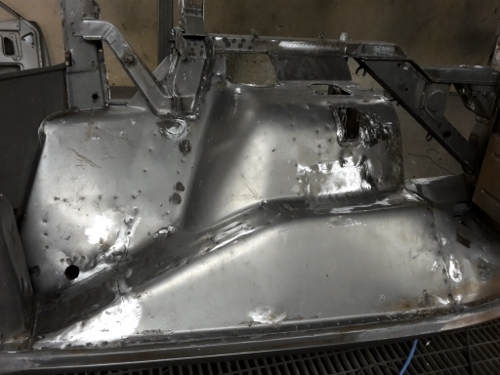

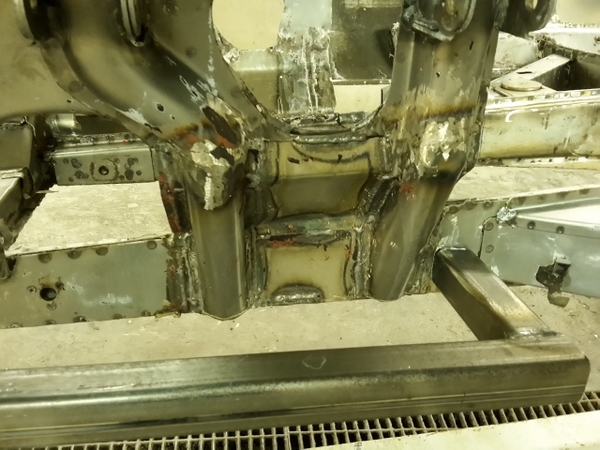

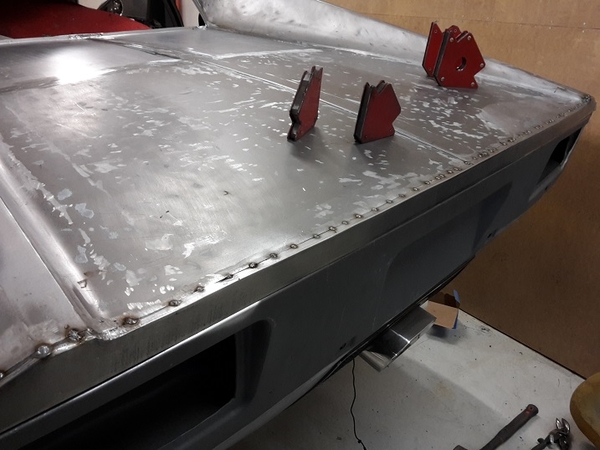

This spring i got a Pantera from Sweden. some body shop had rust repaired and painted it in 1986, since then it has been stored with all parts in boxes. The work they have done on the car is very poor so i have to do it again!

Replies sorted oldest to newest

Keep the pictures coming!

Rocky

PS. I love the rear snow tires.... Are you going to build it into an ice-racer for those frozen lakes of yours?

Simon

especially like the real "gills" and air induction

I like the spin tool for the stacks. That would make a great YouTube video watching the tubing role into the stack..

quote:Originally posted by kim k:

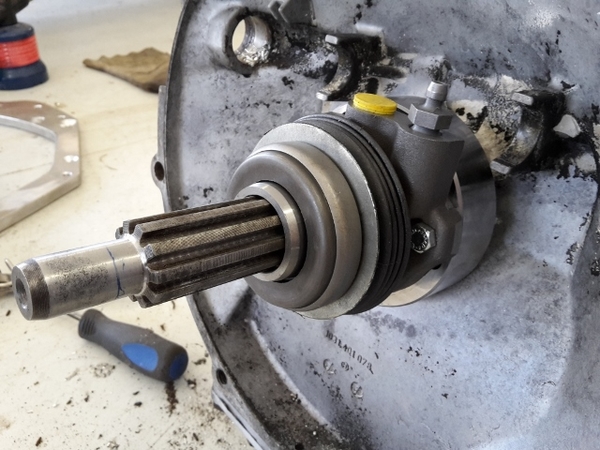

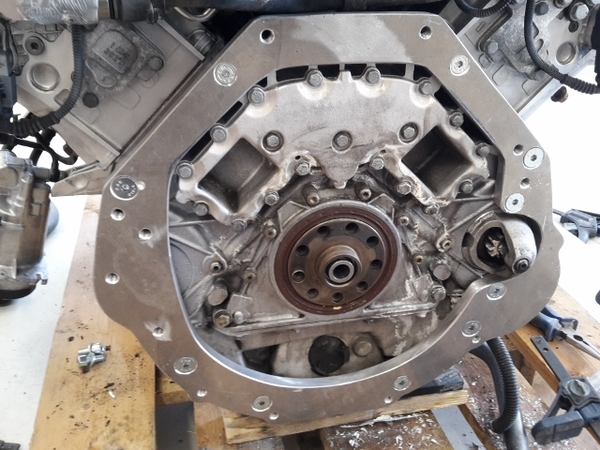

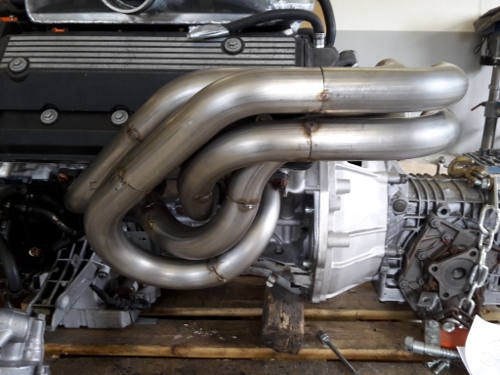

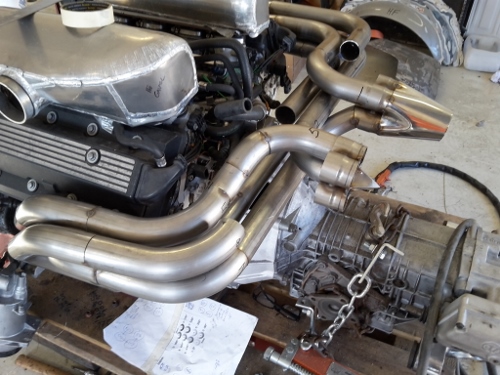

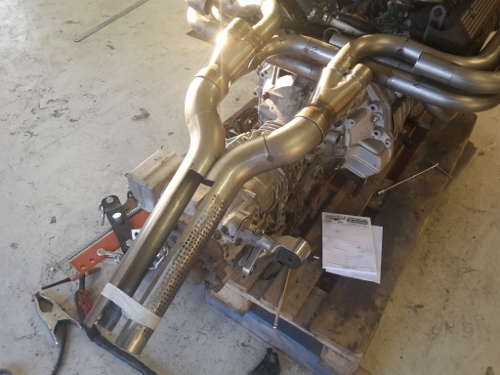

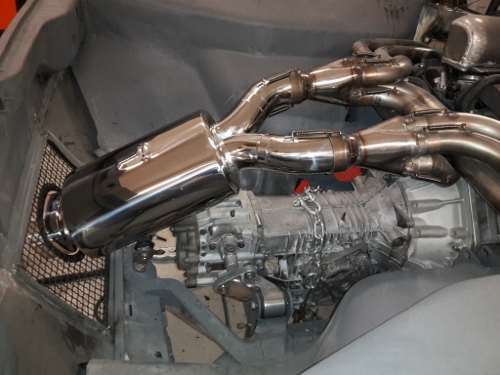

Here is the new engine fitted Bmw M5 S62B50

Fantastic engine! What a challenge to adapt this high tech engine to the Pantera!

Attachments

Btw, which part of Finland you are building this monster?

Vasa on the west coast of Finland

quote:Originally posted by kim k:

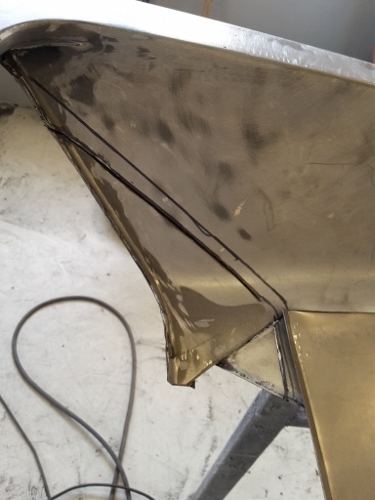

Outer sill

Nice. Can you make an extra pair of these outer rockers, I'll be needing a set.

-Sami

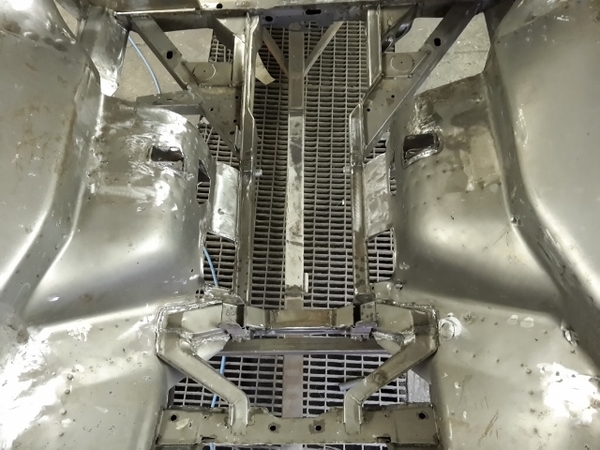

so i first washed away all the residue from the soda blasting and then sand blasted all remaining rust and last a epoxi layer

quote:Originally posted by JTpantera:

impressive work!

thank you !

quote:Does some one of you now if there is any Pantera parts vendors at the Sema Show ?

Unfortunately, there are no Pantera parts vendors at the show.

ZF rebuilder Lloyd Butfoy (RBT Transmissions / High Performance Gear) will have a booth at the show. Booth #24613.

John

quote:Originally posted by jb1490:quote:Does some one of you now if there is any Pantera parts vendors at the Sema Show ?

Unfortunately, there are no Pantera parts vendors at the show.

ZF rebuilder Lloyd Butfoy (RBT Transmissions / High Performance Gear) will have a booth at the show. Booth #24613.

John

Ok thanks

If you have specific parts needs you want to carry home with you maybe you can have them shipped to a Pantera owner in the Bay area for local pickup?

Julian

quote:am going to USA in the end of next week for the Las Vegas Sema Show and to the San Francisco Tesla factory

If you're in the San Francisco Bay Area this Thursday, 10/27, come to the Pantera Club of Northern California (PCNC) meeting at 7:00pm at Holder's Country Inn (998 S. De Anza Blvd, San Jose, CA) and visit with other Pantera brethren.

Garth. The meeting had been nice ! But i am in San Francisco in the end of my trip, Next Friday.

Thank you all for the tips.

Nice Wheels.

What are the dimentions?

Best regards.

Kjeld Pedersen

Denmark

quote:Originally posted by kim k:

The back wheels are more concave than front so the lip is almost the same.

Attachments

Front is 11*18 Tire 275/35-18

Rear is 13*18 Tire 335/30-18

But the molds for them is pretty labor intense so the price for just

the glass to my car is very high,

When the molds is made it is cheap to make more of them!

So to the question is some one else interested in them?

I can handle the orders and ship them out to you!

They becomes cheaper the more that is done.

Then i or we can make an tread about how to get them to fit the doors and the parts needed.

I can also make it a kit similar to the system i chose for my car.

I am not in to this to make money, It is just to get use of the expensive molds!

I am also interested.

Kjeld Pedersen

Denmark

Will the larger glass have any impact on the window being openable? I'm confident that your skills would make it easy to resolve, but would those less-adventurous of us have any problems with that swap? Seems like a great way to modernize the appearance.

Mark

quote:

Looks like you found the solution. It just requires someone following up on getting the contact info of Rick R's supplier to inquire about making some more for those interested.

quote:Originally posted by kim k:

I have been in contact with an car glass manufacturer about one piece side windows for the doors. And i can have them made in 5mm green hardened glass.

But the molds for them is pretty labor intense so the price for just

the glass to my car is very high,

When the molds is made it is cheap to make more of them!

So to the question is some one else interested in them?

I can handle the orders and ship them out to you!

They becomes cheaper the more that is done.

Then i or we can make an tread about how to get them to fit the doors and the parts needed.

I can also make it a kit similar to the system i chose for my car.

I am not in to this to make money, It is just to get use of the expensive molds!

Is this manufacturer guy named Whiantti or something like that?

Dont trust him.

Simon

quote:Originally posted by Marc FG:

Hi Simon - why this concerns ?

Because this guy produced for me the molds for car window's and stole my original windows.

Later he advertised whit those reproduced windows for a cheaper price than I have paid for.

Also I know a case that people have paid for window's but they are never delivered.

Simon

I think it would be best to leave a small triangle i the front for mirror and without it i believe its impossible to get the glass in.

I have been in contact again with the auto glass company about the prices depending on how many i order and they promised to let me know soon!

The company is a very big car glass manufacturer here in Finland they are very professional so no need to worry about that.

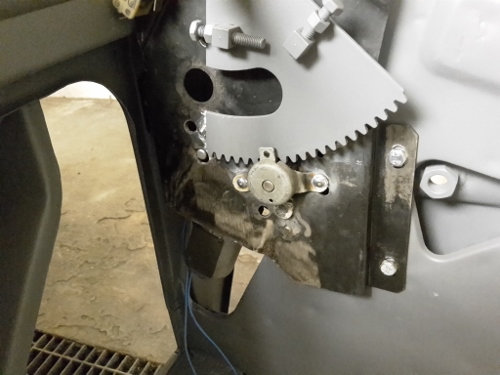

Mark i have not looked in to it so much yet but i think it would be a pretty easy project. when you look at the picture you see that the window opening mechanism is becoming almost centered on the new glass! so i see no need to change that.

But then there is the metal strip under the quarter glass that's need some trimming and the front guides. If i do this i take lot of photos and make a tread.

Its so early in this project so i have not thought about every small detail yet.

If someone have any good idea about this let us know

Its always someone that already have invented your good idea ![]()

I tried to contact Rick R but no answer?

I will let you all know when i know some more!

Attachments

A grand job in the making.

It will grab the girls at the dances in Oulu!!!

great sheet metal job.

Simon

The rear fender flares are beautiful. You have done real talent there. Any chance you could post a few more photos and information on you build process of the flares/fenders?

It also appears from one of the photos that you may building new front fenders. Any photos of those?

Merry Christmas and once again - great work!

Devin

P.S. Your custom wheels also look great.

I know that make the right identical curves into the metal is not so easy as it looks.

Is this your bussinus or only a hobby?

Simon

Simon my business is collision repairs and painting on newer cars for insurance company's!

This is just a hobby and very relaxing when i can create my own form and shape.

When i am doing collision repairs it must look just like from factory if some one see that you have repaired it you have failed

That is why i will never do an original restoration, That is just like being at work for me

Regards

Marc

Any update on the one piece door glass?

Kjeld Pedersen

Denmark

quote:Originally posted by kim k:

Here is 2 pic`s of the air grills. it is strange how the rear fender looks wider with the open grills !

I ordered only my glass for now! so i can be shore that they fit before i get them to any one else!

I made a steel model of it at Christmas that i sent to them. So lets see how it works out! I will let you now.

Hi Chris I made the grill new from steel ! I think that is easier than grinding!? and not so weak because the original part is some sort of cast metal and very fragile.

It would be a lot easier to buy the 5s fenders ! But in my eye they don't look right, I want them to follow the tire as close as possible.

And i have raised the wheel opening so the tire is in right place with the car lowered. And then i also have the front panel 80mm more vertical than oem to flow better with the lowered back panel

Its possible to do on the original 5s fenders but almost more effort than making own fenders.

I also agree with your thinking on the original 5S guards being a little odd shaped - like they're squared off a bit too much around the tyres. That said... if I ever get an original 5S I'll be keeping them stock.

quote:Originally posted by kim k:

Thank you all for the nice comments!

It would be a lot easier to buy the 5s fenders ! But in my eye they don't look right, I want them to follow the tire as close as possible.

And i have raised the wheel opening so the tire is in right place with the car lowered. And then i also have the front panel 80mm more vertical than oem to flow better with the lowered back panel

Its possible to do on the original 5s fenders but almost more effort than making own fenders.

Yeah, nice custom fix around the tire. Plus I thought real 5S fenders were almost impossible to find anymore anyway. I know a guy that did a custom build with special made carbon fiber 5S style fenders, and he shaped the wheel area to be rounder as well to hug the shape of the tire.

quote:Originally posted by kim k:

Thank you all for the nice comments!

It would be a lot easier to buy the 5s fenders ! But in my eye they don't look right, I want them to follow the tire as close as possible.

And i have raised the wheel opening so the tire is in right place with the car lowered. And then i also have the front panel 80mm more vertical than oem to flow better with the lowered back panel

Its possible to do on the original 5s fenders but almost more effort than making own fenders.

I have to agree. I have always thiught the wheel opening should follow the wheel. Can you make a couple more?

It looks fantastic!!

Realy nice metal Work.

Are you using some kind of rubber for covering the gab between the glas and the frame or only the glue?

Kjeld.

quote:Originally posted by kim k:

In place with old glass

quote:Originally posted by DOES 200:

Yeah, nice custom fix around the tire. Plus I thought real 5S fenders were almost impossible to find anymore anyway.

I am told Wilkinson has a couple sets of original 5S fenders, but wants to do the work not just sell fenders. Retail price on the originals is over $15K, fortunately I have set stored away.

The aftermarket variants are just side pieces you cut in and are hand formed over dubious bucks.

Personally I do like the squared off look, it adds another angle IMO.

Julian

Julian[/QUOTE]

I agree whit you Julian,

Simon

I must have the car here to fit it to or its not going to be any good .

Its ride hight, type of wheels, different front panels,difference between cars and other things that make them diverse.

Kjeld

I am searching for a very small rubber strip but have not yet find any. One option is to just fill it in with glue. I have tried various models but all is to big so far.

I am very glad to hear that some like my type of fender and some not, That is why these type of forums is so interesting if all would have same taste here would only be the same black car.

Regarding ruber.

If i remember Right on the old Opel kadett e it was possible to get a aftermarked rubber to use if you cut the original rubber for painting the car without removing the glas.

I Will find out and let you know.

Kjeld

quote:Originally posted by kim k:

I am very glad to hear that some like my type of fender and some not, That is why these type of forums is so interesting if all would have same taste here would only be the same black car.

Please don't misunderstand, I don't dislike what you have done, I just prefer the original concept. I have a lot of respect for what you have done and the work involved, it is far beyond my skill level. I suspect that is why the vendor fenders are so many welds, as they are not true experts in metal shaping like you.

Julian

I was not offended at all ! I just meant that it is nice with so many different tastes on this forum and every body can agree on some level !

(Try to post a build like this on a Ferrari forum that's scary)

I really like when you all comment my build

Its some times hard to formulate correct in english what i mean.

I find one i will use for my build.

Mabye you can use it also.

It is universal for 5mm glas.

The total Width is 16mm, made of veary soft rubber.

Price in Denmark 38.00kr each meter.

Best regards.

Kjeld.

info@servicegear.dk.

Attachments

Attachments

Yes that would be one option! That is closest so far, I have one similar but it is 20mm wide and that is to much. Ideal would be something about 10mm and really flat shaped!

quote:Rubber for windscreen.

I find one i will use for my build.

I'm confused.

Why are you sourcing a non-stock windshield gasket when there are readily available quality gaskets available from our vendors?

Perhaps I've missed something in the previous postings, if so please clarify.

Don't understand why one would feel inclined to reinvent the wheel for such a part.

Larry

I am thinking that a standard glue-in windshield uses adhesive designed to adhere the glass to the car body's metal.

IMHO, incorporating a flexible, subject to deterioration, rubber gasket into that glued joint would make that installation much less solid, secure, and durable.

Or are you somehow installing the rubber gasket after the windshield has been glued to the body?

Is there any standard production vehicle that incorporates such a glue-in/rubber gasket installation method?

I'm just not seeing good results from this approach.

Again, I may have missed something in a previous post. If so I again seek some clarification.

Larry

Flush Windshield by JanDaMan, on Flickr

Flush Windshield by JanDaMan, on Flickr Flush Windshield by JanDaMan, on Flickr

Flush Windshield by JanDaMan, on FlickrThe glass factory had problem to get enough radius on the glass . It had something to do with the hardening process. but when they had tried a few they got it pretty near. But i had to take a little radius of the window frame(straitening) and make a little more radius on the vertical lifting mechanism! So now its working good!

and the glass is also E-marked =legal

Attachments

price for both is 740€ +shipping

I am interested.

Please contact me on info@servicegear.dk

Kjeld.