Beautiful build! Keep the pics coming.

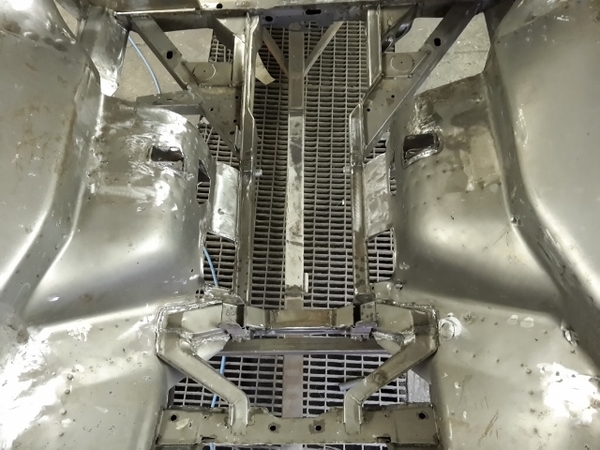

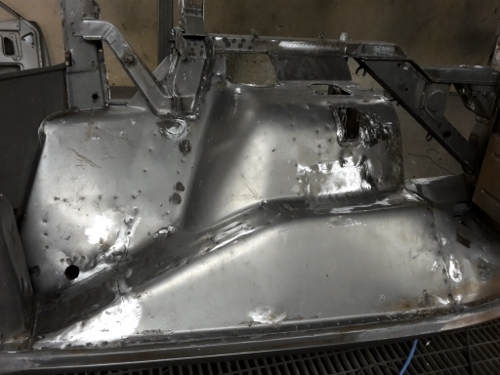

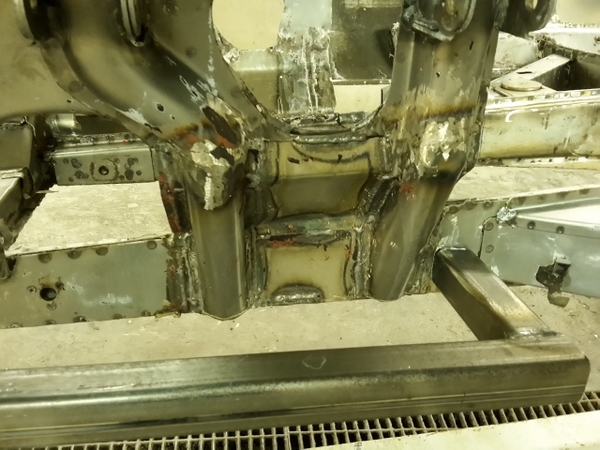

now i have got a little done again. now when the winter is coming the body really need to get som epoxi protection and all the structural work is done.

so i first washed away all the residue from the soda blasting and then sand blasted all remaining rust and last a epoxi layer

so i first washed away all the residue from the soda blasting and then sand blasted all remaining rust and last a epoxi layer

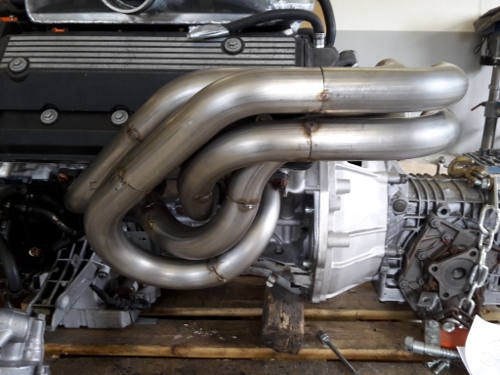

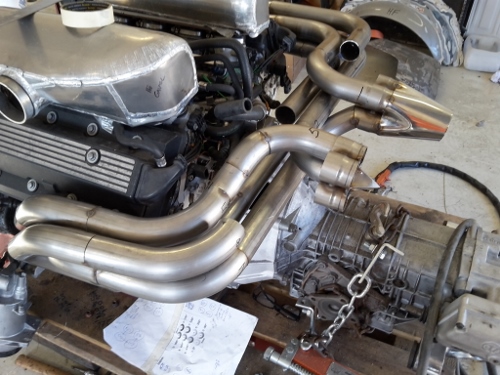

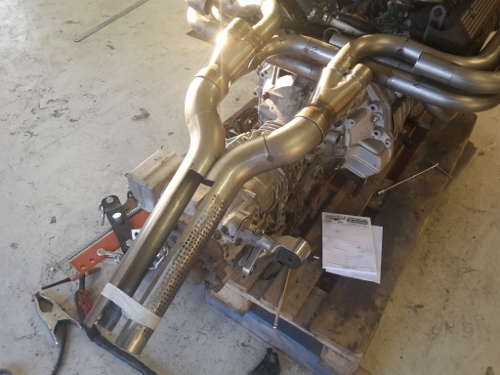

Interfacing the BMW EFI to the Pantera wiring will be interesting.

I am going to use MaxxEcu engine management system. To use the BMW original system i think is almost impossible. MaxxEcu has also a good system to control the vanos.

Add Reply

Sign In To Reply