quote:Originally posted by PanteraDoug:

Just convert the degrees into inches or mm. Put a bolt through the level (thread the level) and adjust the bolt to what you want for camber and lock it in place. Then you can just use it for a "quick check" by holding it up to the wheel.

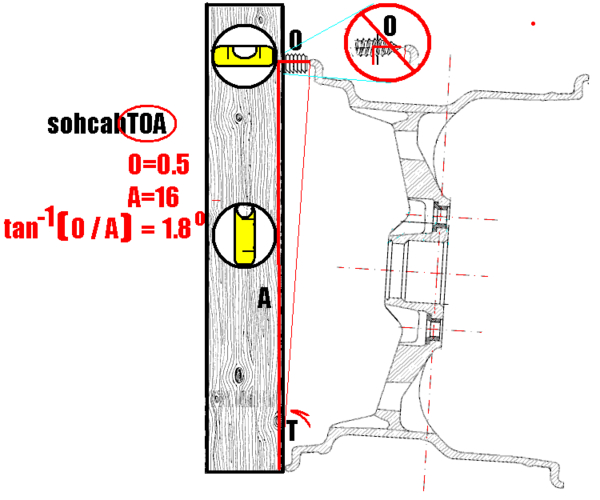

SOH, CAH, TOA, on the geometry, or is that trig? I think that works out to 1/2" on the camber on a 16" level?

considering below recomendations, edited the illustration to remove the "mansonary screw" and replace with bolt threads

Attachments

My tape measure is in inches with a secondary metric marking.

I know of none, including mine, that is marked in degrees or what tan .03125 means in degrees?

Make this easier, not harder.

Sounds like the kind of place that you need?

Don't be surprised if they say something like "try this" setting, with their numbers (not mine or "ours")?

I don't think anything is written in stone? Driver input is important. If the car doesn't feel right then something needs to be done.

All of those "chart settings" are for a box stock "production car". As soon as you change anything, they mean less and less.

PROBABLY "auto cross" guys can help you the most since those settings are the closest to what you will be driving on the street.

It makes little sense to set the car up for 200mph. That's just some kind of an ego trip. The big caster numbers are the biggest part of that. 6 degrees is for 200mph, not for autocrossing around a parking lot. Stock 73-74 castor is plenty for that AND high speed events that you do "once in a while" or even once in a lifetime.

Stock, a Pantera was set up NEW for virtually anyone in the US, to jump into the car and go fast. With that set up, you run into a wall though. That wall is around 150mph. Over that, different factors come into play.

150 is about what a novice in a Pantera can handle ON THE STRAIGHT in a Pantera. Over that you need LOTS of experience. The required experience is also specific to that car in my opinion.

Best of luck with your endeavor. ![]()

quote:Originally posted by Robbie:

Opps .. a ps .. 72 pre-L, SN 3518.

Robbie we could be related mine is 3840 a July

72 Euro GTS,

sorry to crash the post lads.

For those of you who are using a shaved upper ball joint to get more caster, do you know the amount to mill from the edges of the ball joint? How much additional caster can you get from that?

My car is an early '73. Are the '71 upper A-arms or ball joints different and enable larger caster settings from stock components or are they just located in a slightly different location?

Many owners successfully use 0.090" or 0.100" shaved from one side. This is a safe amount that does not fall into the grease cavity for the ball joint. Good for about 1 more degree of caster additive to whatever else you use.

The front suspension for very early Panteras/pushbuttons is considerably different than what was used in the first revision for production. Looking at the Illustrated Pantera Parts Manual will show the myriad differences in upper a-arms, steering arm, upright forging and removable spindle. Alignment specs were also different since neither coil spring spacers nor bump-steer spaces were used. This is pure Dallara. Later was Ford engineering.

@bosswrench posted:Many owners successfully use 0.090" or 0.100" shaved from one side. This is a safe amount that does not fall into the grease cavity for the ball joint. Good for about 1 more degree of caster additive to whatever else you use.

Larry Stock offers the ball joints pre-shaved. It takes a 5/32" shim. I don't know what that translates to in the amount he cuts off?

I can't get a straight answer from him other then he gets about 4.5° total using the shaved ball joint and offset bushings which he carries also. By deductive reasoning the offset bushings must be around an additional 1.5°?

In a '60s Mustang that would be a large change, adding 2.5°, with a noticeable increase in effort with manual steering. Been there, done that.

He says there is no noticeable change in effort to him going from the stock 2° to 4.5°.

I would presume 4.5° would be a significant change in directional stability in the Pantera as well?