Brand new build with all new parts.

351c sleeved back to 0

stoked for a total 402ci

CHI 208 raised port

cylinder head gaskets installed correctly

thermostat validated in water to verify it begins opening at 180

using a stant 180 with a block off plate

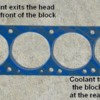

air bleeds installed in the back of each head

sk32-541-8 cam

ron davis radiator with sucker fans that starts to get warm

eldbrock water pump with impellers going the correct way

over 3 days of testing, bleeding air out, etc. the passenger side starts to steam after 5-10 minutes and the drivers side is fine.

looking for ideas... disassembled the motor an we're not finding anything obvious. Current thought is maybe some blow by but if so there's no obvious signs.

thanks Rick.

Original Post