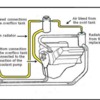

Hello lovers of beautiful Italian American Lady I am currently in the process of restoring my Pantera L 1974, and I would like to know the best cooling system between these diagrams. Thank you for your support Willy

Hello Willy,

I am not going to select either of your suggestions as being better than the other

instead, I am going to ask you why you feel the need to deviate from the original factory design.

there are still thousands of Panteras, stock and highly modified, that still use the original design, though often with improved radiators and water pumps.

I personally do not see the need for modification of the original cooling system, as it will function just fine.

Larry

The purpose of George's cooling system mod is to make the cooling system self bleeding. It's always a headache getting all the air out of the system and with the mod, it does it automatically, as you drive. I did it to mine but I was building an entire new cooling system from scratch. If you use a vacuum filling device to fill your stock configuration cooling system with coolant, air won't get in, in the first place.

Good morning Larry,David

Thank you very much for your analysis, I had to change my radiator and replaced it with a PI Motorsports, Inc. Pantera aluminum radiator. So you advised me to keep my original system, if I understood you correctly ?

willy

See my answer here:

https://pantera.infopop.cc/top...92#25261151688862692

The second diagram also allows an automatic purge.

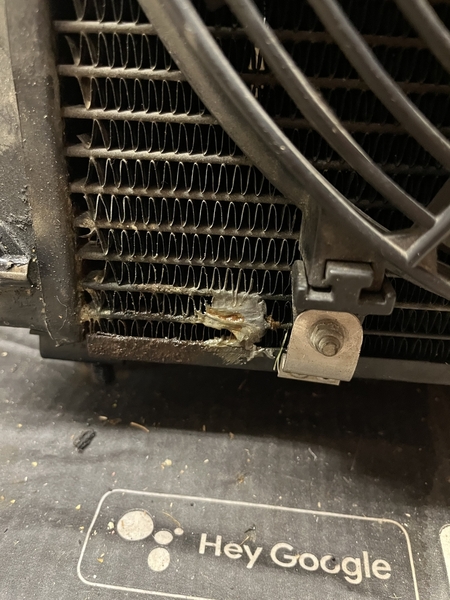

My radiator journey starts with no problem increasing to a gallon on the floor. Naughty girl.

My radiator journey starts with no problem increasing to a gallon on the floor. Naughty girl.

It gets understandable once the old copper radiator is out. There is a spooge repair down in the corner.

I went with the fluidyne solution. I found the same delivery problem. Bent mounting ears.

There was equal treatment for both ears.

Bent em back with wood blocks, table vise, and then c clamps. Attle be arrrite. On on to mounting fans. Also… the recommended dual fan enclosure from this list is no longer available. I will pop rivet some brackets. I figure aluminum on aluminum might corrode less. Use that flange around the edge. Reuse the bracket you can see in the spooge picture.

Attachments

Where did you buy the rad from that they can not figure out how to package something like that. Let us know as I will not buy from them.

Well. Summit. I’m not sure you can blame them. It appears it was drop shipped this way. Fluidyn ships in cardboard using expanding foam over plastic film for protection. Those ears stick out and are very soft metal. Without rigid protection, hmmm.

Im the second person in this thread to see this happen. Scroll up to see the other. I’m not letting this stop me. I’ve worked through lots of problems getting this car to reliable. It’s my date night car. No sex until it’s perfect! (Kidding)

This is not the thread, but here is my amp meter insulation:

That is a custom masking tape and window caulk spooge iso 5000 compliant and waterproof to 10 meters. Under it, is an 18 gauge jumper wire between the amp meter posts. Considering this takes all the current the car can generate, great idea. I live a life of danger! I got Jon to fix the amp meter and put silicone boots over the posts, wires, and retaining nuts. I added grommets cut in half to the post base to eliminate air gap. I yearn not to burn. Happy motoring.

Attachments

Kemper, the traditional dual-sucker-fan-with-shroud that fits Pantera radiators perfectly is the Flexilite (didn't save the model). If thats the one you say is no longer available, Maradyne Co makes one virtually identical. PanteraParts.com in Carson City NV stocks them. You can improve these dual-suckers by making sure you have full battery voltage to the motors. A loss of 2V will cut fan speed by almost 40% according to my tests.

Here's the Maradyne catalog. Which one is it Boss? thanks

Attachments

If the fans are mounted in a shroud and there's no baffle between the fans, make sure both fans turn on and off at the same time.

I had 2 bent radiators from summit. Boxes were in perfect shape so it is an internal Fluidyne issue. I called Fluidyne and they took extra care to make sure the brackets were good on my 3rd radiator. I could have bent them back but I was concerned about the load that the radiator experienced that caused the bent brackets. Plus I was pissed after spending $700 and seeing this poor quality!

I could be happier. My concern was metal fatigue. That is a very soft aluminum so, maybe less fatigue than a stiffer grade. My new concern is weaseling it into the car with slightly deformed ears. The fins are super thin. Breathing on them might cause bending. A bump would leave a mark. I am pleased the shell around the sides over hangs and is spaced away from the core. That will make it easier to attach the fans.

Soon I will try the tip I read on here of putting my hoses in boiling water before pushing them on larger inlets to get those 1 3/8 hoses to 1 1/2. Hope they hold the new larger size when cooled! Happy motoring

New question. I'm swapping over the two thermostat switches. They appear to have a shoulder that would take a washer of some sort to seal them. Mine are mostly gone. What used to be between the switch and the radiator? What size is it?

Secondary question. What size is the radiator switch. I used an 1 1/8 socket and it worked ok for one but was a little small for the other. Thanks!

They're probably metric hexes. Depending on the radiator, some were VW thermoswitches.

I measured the hex on one original and one aftermarket temp switch. Both measure 29 mm. Threads are M22-1.5.

Make sure you check the threads in the radiator tanks. Some owners have reported that the threads on their new radiator were in poor condition.

The temp switches require a fiber washer / gasket. Aluminum replacements are sometimes available.

John

Nice tips. Will check the threads. I calculated 1 1/8 was 28.5 mm and was guessing 29. Now I’m not guessing. Will pick up a 29mm deep in 1/2”.

could I bother you for the dimensions on that gasket? I can put a caliper on my thermaswitch tomorrow, or see what Napa has tonight. I may have to make this. Bespoke gaskets ![]() . The list of things I make for this car is growing. It’s worth it. I’ll try “vw 29mm temperature switch gasket” and see what. See how good my google-fu is.

. The list of things I make for this car is growing. It’s worth it. I’ll try “vw 29mm temperature switch gasket” and see what. See how good my google-fu is.

I also have the famous Cleveland oil leak around the sender. Anyone ever built this area up? Any solutions besides permatex “forever” thread sealer? So hard to remove that stuff.

Thanks everyone!

Found

N0438083-VR

and ordered that from Pelican thanks all.

Be sure where the oil is leaking from before you knock yourself out. I've had senders that leaked inside the plastic body and came out around the crimp connector!