Just installed Wilwoods and they look amazing. Fronts fit perfect, but back rims hit the edge of the calipers. Can I machine my rims to fit or use a spacer? Anyone else had this issue? TIA

Replies sorted oldest to newest

Definitely don't machine the rims. I imagine you can modify the calipers but, as I recall, the amount required will adversely effect the caliper. I'm surprised the fronts fit as I have heard the Wilwoods don't work with stock wheels.

Do you have 8" or 10" rear wheels?

No you can't machine them. You need to match the wheels to the braking system OR braking system to the wheels.

You just can't arbitrarily apply parts. There is "some" engineering involved.

DeTomaso machined off a bit of the inner ribs on the rear 10” wheels, on the factory GT3 cars with the larger rear calipers.

They are 10” in the back. The instructions do you say they fit under MOST 15-inch wheels. The amount they are rubbing is very minimal. Curious to know why I couldn’t machine off a few mm in the spot it rubs? What do most do? Buy new wheels?

Did you see my posting on this topic? When Dennis Quella started selling Wilwood brake kits in the ‘80’s, we all still had 15” wheels. Dennis would grind the casting tabs off of the calipers he supplied. As I stated in my previous posting, DeTomaso machined the 10” rear wheels to clear the brakes on GT3 cars. It was only the strengthening ribs that interfered and the amount they removed from the ribs was minimal; only about 1/16” from the thickest part of the ribs.

@USCDOC13 posted:They are 10” in the back. The instructions do you say they fit under MOST 15-inch wheels. The amount they are rubbing is very minimal. Curious to know why I couldn’t machine off a few mm in the spot it rubs? What do most do? Buy new wheels?

First off, when you buy a set of upgraded brakes you are buying the engineering of them as well as the parts and not just lip service and a bill of goods.

It's easy to criticize other's decisions of what components were chosen and why.

Personally I would go back to the seller and request that they correct the situation or take the brakes back. You CAN make a case rather easily of them selling them to you on the premise that they said that they knew exactly what they were doing with a Pantera to begin with and it appears that there was an oversight.

If you bought them yourself based upon your judgement, then you are the engineer and...ooops! ![]()

It may be true that the Detomaso race cars were machining the 10" x 15" Campi wheels for additional clearances. Actually when I see the calipers that they picked to race with it suggests to me that somehow their combined thinking on the subject was very limited or at least limited to alternatives to them there in Europe.

Engineering wise it may have worked for them but I wouldn't have gone that route because the solutions to me just plain suck.

Panteras being raced here in North America had a better selection then of brake systems. With the exception possibly of the one Group 4 car, the few others racing were converted street cars that the two that I have seen were running the "Big Ford/Lincoln" calipers and rotors in the front and 65 Mustang front rotors and calipers in the rear.

Those were the brakes being run by Mustangs running in "Trans-Am" at the time. The system proved itself dependable and capable of the "suicide" type racing of those cars.

Those are probably more brakes then will ever be needed on a Pantera and the components are still available for it with the exception of the Mustang rotor, but you can still use your Pantera rear rotor with it and there is positively no clearance problems involved on the 15" rim.

The main issue with that set up is you need to rebalance the front rear braking bias and in the past, there was no parking brake for it.

On the Pantera, now you can use the electronic parking brake assembly from the Tesla.

Why shouldn't you machine your 10" Campi's? First off, they are somewhere around $2,500 each to replace. Second, they are 40 year old magnesium castings. I personally wouldn't just dismiss anything on those wheels as being "expendable". They are thin castings to begin with and as always x-raying something like that is a good idea BEFORE "you cut".

No one here, especially me is going to tell you what to do but as they say in politics, "to the victor belongs the Spoils". You modify them, if there is no problem with them, fine. If they fail under stress, maybe you get killed too?

Those wheels where probably $100 or $150 a piece cost to Detomaso at the time in the early '70s? If they broke one, "so what?" ![]()

Exactly where on the wheel is the contact? If it is the ID of the wheel, the issue of correction should be left to modifying the caliper and not the wheel. If it is the back of the spokes, use as thin a wheel spacer as will fix the clearance BUT watch your lug nut to stud engagement. Use generous amounts of "anti-sieze" on all the studs.

IF you look at the Detomaso "racing" parts illustration I believe that you will see that a wheel spacer is to be used. It being a diagram it does not specify when the spacer is needed with what parts

Wow thanks so much for the information! I love hearing the Hx. I think I’m going to try as small wheel spacer as possible like you suggested. I’m only finding 5/16” locally. I could probably order a smaller size online. You are correct, the interference is fractional. Here is a pic from me putting on the wheel and spinning it. Do you think there would be any problems from using a 5/16 spacer? TIA!

Attachments

I have some 5mm spacers so they are out there. What you can do is try hardened 1/2" flat washers (Home Depot or Lowes has them) and you can buy 1/2" id round hardened shims. Those will come in thicknesses all the way down to a few thousands of an inch so you can really measure the clearance issue quite accurately with stacking them up until the wheel clears.

Washers CAN be problematic since it is possible that even if you have the stack up equal on every stud it could still be off and the wheel spin off center. Now on the back that is less of an issue BUT still could be an issue.

On the front you would feel it right away in the steering wheel because it would wobble.

At least if you sart with the flat washers, it will give you a very close approximationtion to what the thickness of the spacer should be.

As far as how much thread you have engauging, you will need to measure that once you have the spacer set. !/2" is about the minimum that you want.

Rear studs on a Pantera are not readily available in other then stock lengths. You don't want to have to do them if you don't have to.

The Pantera race cars that I have seen look like they have been converted to SAE 1/2" studs which you can get from almost any race supply shop. The rears are special. I don't know of any other car that uses the Pantera rear studs.

It's possible that ARP may have something in the catalog that would work if you need to go that route. Here's hoping that you don't.

Looking at the interference on the ID of that wheel, that looks like the caliper adapter is off a little on the bolt center lines? IF there is clearance between the OD of the brake rotor and the top of the caliper, you may be able to remake the adapter and bring it in 1/8" or so and that would fix your issue there.

That is not an unusual circumstance on race cars where the caliper is "adjusted" so that the brake pad is contacting the rotor at the maximum area. Production mounts are often off that mark by sometimes up to 1/4".

It may also be possible that if you loosen both the adapter and the caliper and tap them down with a rubber mallet while the bolts are in but loose that you will be able to gain enough clearance without going further.

The other thing that you could do is just let the caliper "clearance" the wheel itself as long as it is basically just wearing off the paint. You DO NOT want the caliper to "score" the wheel completely around it's circumference. That would be encouraging a "failure" through that line as if you cut it on the lathe.

Remember though that magnesium is porous and needs to have a sealer over it so the air molecules do not pass through the porosity when the wheels are cold. That's not a joke, that's for real. They won't hold air unless they are coated.

The back of the spokes has to be done with a spacer. Do not cut those wheels. That may sound good providing you have a lathe that you can get a 15" wheel on? Those are the big mama lathes and few shops have those around anymore. Those went out with the Navy battleships like the Missouri.

Thanks so much for the info. Great ideas! I determined after taking it apart and reassembly ad nauseam, that the 5mm were the closest for the rear. No spacers needed on the front. The instructions say to sand the brake caliper. I think that's poor engineering to be honest. I mean come on it's an e-brake caliper. They couldn't just give us a solid 1/4 inch space?! I hate to have to modify the "aesthetics" of the brakes that were supposed to be designed for the car. I've heard that there were a few molds for the wheels? Not familiar with magnesium, but do they cast that? Just bummed I have to remove nearly all the red paint off of one brake caliper, and then Wilwood tells me they don't sell a touch up paint for it b/c it's powder coated. I realize it doesn't effect the functionality of the brakes, but still pretty shocked after installing Wilwood on multiple other vehicles that I'd have to "modify" them b/c they only fit "most of the time". They have been providing Wilwoods for Pantera for a while... why not modify them for 100% of the stock wheels or is that not possible? My OCD will find a matching color eventually unless someone already knows it. Bare metal needs to be covered to prevent it from rusting in my mind.

Why not disassemble the PB caliper, have the necessary amount of material machined off and then have it re-powder coated? You might want to try Cerakote as it's thinner than powder coat.

As an alternative you could send the PB kit back and use the OEM rear caliper as a parking brake but depending on the size of your rear rotors, it may require some modification to fit.

If you need longer studs they are readily available, the GT5/5S uses longer studs for the wider Campi wheels.

I got lost on the discussion is this a brake caliper or a parking brake? Where did you purchase the kit?

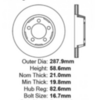

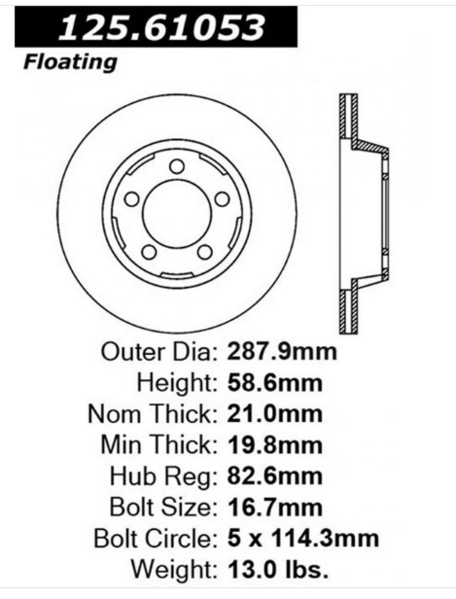

Since you are only dealing with the problem on the rear, possible the Centric/Stop Tech OE spec vented rotors #125.61053 would work, they are about .250" (11.25") smaller than the OE rear rotor diameter. Maybe have new mounting brackets made so it pulls the caliper closer to this rotor until it clears the wheel.

They are nice rotors, high carbon, vented and were made at the urging of Mike Drew as replacements for stock front rotors. They're a bit lighter since they are vented and the hat area aslo was cast with large holes to lighten the rotor. I bought a set for $42 each, they are now $78 on Amazon https://www.amazon.com/gp/prod...le?ie=UTF8&psc=1

Attachments

Tom,

IIRC Mike arranged a special run that was just the rotors, and the castings did not contain the bearing hub

The common problem with the mustang rotors is for efficiency reasons almost everything currently being made incorporates the hub and rotor into a single casting. They come with SAE studs that cannot just be removed and easily replaced with matching OEM metric studs.

I know the image in the Amazon link shows just a standalone rotor but I would not take that as indicative of what would actually be shipped

The Amazon listing doesn’t indicate free returns but I believe that is a standard even with third-party shippers. This item does not ship from Amazon so I would advise contacting the actual seller to learn if free returns are offered should the items delivered not be what was hoped for

Larry

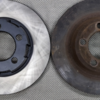

Hi Larry, the rotor in the picture is identical to what shipped. My old rotor is identical except for the new one is vented the OE is solid and the hat sides on the OE rotor is solid and the new one has holes I assume for cooling and litening the rotor. They are incredibly nice!

Attachments

Yes Tom, I understand the rotor you bought from the …..bulk purchase….. done by Mike Drew appears to be the same as the ……Amazon……. image.

all I was trying to convey is that images are VERY often not correct. Many other owners have thought they were receiving a standalone rotor based on a photo but as I explained, photographs are often incorrect or not updated to depict the current offering

Larry

Changing the rotor does not change the mounting position of the brake caliper and it's interference with the wheel.

If the rotor is .25 smaller than the existing OE rotor, and a new bracket is made to move the caliper .10-.20" closer to the rotor which is smaller, the caliper may now clear the wheel without machining the wheel or the caliper for clearance.

I think the original poster is seeking a solution that doesn’t require the machining of new parts …and… purchasing standalone rotors which will most likely prove to be an impossible task.

Larry

If that's your plan, you could also take your existing rear rotors to a machine shop and have the OD turned down by 1/4". Even 1/8" might be enough. Will the main calipers and pads be OK with a 1/4" smaller OD rotor?

That being said, it seems like a lot of work when you could simply grind some material off of the parking brake calipers. It would accomplish the same thing and eliminate the need to disassemble the rear uprights to remove the rotors.