as I am working on the upgrades on my brakes to Wilwood I discovered something really funny and disturbing:

the poly bushings do not have an insert never saw anything like that!

i’m going to replace them with the original style rubber bushings

I also replaced the dust covers on the ball joints (which absolutely felt like new) , which was a very simple and satisfying procedure! Pulled out the old remains and took out the spiral spring steel ring that holds the dust cover in place!

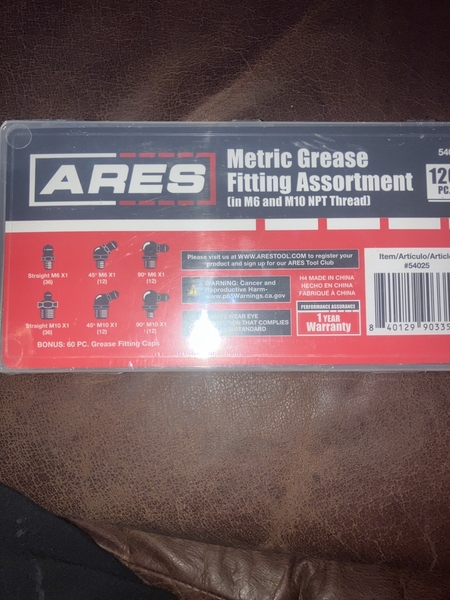

cleaned out all the old grease and repack them with new ones and put the new dust covers I got on Amazon on and “screwed “ the spiral ring back in position!