Joe

Great to see the progress shots . It is always hard to keep the momentum going after the third year !! Keep at it - the overall end quality will be better than new !

Perc

Joe

Great to see the progress shots . It is always hard to keep the momentum going after the third year !! Keep at it - the overall end quality will be better than new !

Perc

Looks great! Congrats!

Real progress, looks great! Maybe you will be driving it before the end of this year?

Wow!!! Awesome

@racecarmike posted:Real progress, looks great! Maybe you will be driving it before the end of this year?

that was hoped

BUT, A mix up on the wheels will be a couple months before they come back. (I think they are on a boat to Italy via Panama and the Suez)

speaking of this. . .

Is there 15X7 and 15X8 aftermarket wheels that would work till Campy's come back

MANY years back I got a SS exhaust by Wilkinson (new, second hand).

The shop rebuilding 5177 called to say the driver side is not fitting, interference with gas tank shield and engine mount. (info second hand from Techs through Manager)

My response was it was OK to hammer tubes. I thought I read this has been seen before and forcing tubes would make acceptable.

Is that so OR is there something else?

There was an article in which I believe was in Hot Rod magazine if I remember correctly where they dented some of the primary tubes and it didn’t affect power. They could possibly modify the tubes which would be more work.

Dear JFB,

I have had driver's side header primary interference by the motor mount and gas tank on two sets of GTS headers over the years. On the first set, I discovered years later that the BFH approach was used to obtain suboptimal fitment. With the recent second set, I was smarter and checked with an exhaust expert. His method is to heat the area of interference with an oxyacetylene torch to orange hot and while the steel is relatively soft, then apply a round (various diameters available) to the problem area followed by judicious whacks with a BFH.

The common BFH method applied to cold steel, in my experience, results in a mechanical reduction of ugly appearance. The oxyacetylene BFH and round tool combined with a BFH produces a better esthetic result.

Obviously, not many people will observe such things given the location of the corrections on the primary tubes. Also, my headers were not stainless steel, which may be a important point. It is good to know your options.

Warmest regards, Chuck Engles

I have recently installed two sets of Wilkinson's stainless exhaust and was able to get them into the cars without massaging the header tubes. Instead I used an air file to slightly shave the motor mount and also slightly relocated gas tank shroud. Wilkinson said the he header tube should not touch the shroud and that the smallest of gaps is sufficient.

I did this years ago when Wilkinson first sold these. The answer was as Steve said to shave down the motor mount.

Congratulations!

Must be exciting after a long journey!

Would be grateful of the cam specs if there available, is it a stroker? did i read correctly you made 475 ftlb that's great with that idle.![]()

I've actually "lost" the specs I provided for the grind. I think G Pence changed to specs in post. I do not have any output expectaion values.

The restro shop ia suppose to have keep the paper work from the grinder.

That vid is sopposedly the first crank and no tuning done yet, I am interested in idle and vacuum

bore and stroke are still 351

Ok thanks I see it was Larry's post with some dyno numbers

That’s great news!

Very nice 🙂🙂

Ah, the advantage of an 8 digit custom plate. No one will understand what it means but......

I got up nerve to make the 7 hour RT.

only had a few minutes to look /talk. I did check the clutch effort. while doable, it could slide me accross the dynamat

After being refurbished by ""ferrari shop" the wheel look great, EXCEPT the color is slightly darker.

And today they sent pics with doors and hoods on. I hope the engine screen will clear a factory air cleaner

It’s coming together! Are you seeing the light at the end of the tunnel?

PS… From what I am seeing in the pictures, it looks like very nice work!

Congrats!

jfb,

If you're in the area again, you're welcome to stop in. I'm in Greensboro.

Congratulations on all the progress! Looks great!

Just gettin caught up JFB…. Long journey, for sure, but she’s lookin awesome man!!😎👍

As for "seeing the light at the end of the tunnel" ie, getting 5177 back, I still have a bad feeling !

Slow progress is exactly right though. I AM keeping this post as up to date as things happen.

Today, pic with the refurbed wheels and BFGoodriches on.

AC installed and checking with vacuum.

there was a "problem" getting original type air filter on. . . interferance with new distrubutor, but that was resolved.

EDIT....

Anyone make their own center caps? If so diameter (& thichness) would be appreciated.

I am thinking about a polished (chrome) with just the “cattle brand” engraved.

Joe…

I have an old brass one on my display shelf.

Just grabbed a dial caliper…

dia. => 2.336” -> 59.3 mm (60 mm?)

thick. => .044” -> 1.17 mm (1 mm?)

My stock wheels are in a storage unit, so I couldn’t test fit the emblem…

(Someone will correct me if this medallion isn’t sized for wheels…)

Ps. Car is looking good! Coming together!

Looks Great!!!

Would you recommend the shop? Asking because I have a half finished car.

Thanks, Mike

what is your budget? I am embarrassed ti even mention what this has cost (and it is not finished AND I am supposedly being given special considerationI would ) The Owner seems to be a Great Guy, very knowledgable, and I thinks His initial intentions to "help" me were good, but his buisness has changed (gotten bigger). I think the work is concourse quaility. Dealing with the several "project mangers" has been EXTREMELY stressfull.

I don't think (and been told) their normal customers don't have specifiec way they want the car to be.

This is as much as I want published

I would highly recomend visiting his shop (https://klassicrides.com/) and asked to see 5177. the Owner is Billy and my current project manager is Rob (never met him)

Hey Joe - keep it going- you are so close !

Had the same wilkinson 2 inch header interference issue myself but chose to carefully ball paen the new Stainless heat shield on the fuel tank as the solution. It seemed to work and did not compromise the pipes. I had a 2 1/2 inch big bore header set previously installed which had some serious tap dancing on the pipes to be made to fit so this is a common issue.

Just aa question - did you replace the AC piping and do you have advice on that ? Did you refurb or replace the under dash fan unit ? The TX valve ? Still got to do this and all advice welcome.

Perc

My "instructions" were to replace AC with modern unit and controls. I can't recall but something like a Gen II unit was suppose to be a near drop in. The First project manager had other ideals and he purchased a Gen I unit, disassembled, threw away the controls and fitted the core, evaperator and fan on exisiting box (plus a LOT of labor charges) He planned to use heater slide lever with long cable to an engine location heater valve.

Our disagreements lead to owner assign new project manager and He was not going to use the long cable so I DON"T know how controls will work. actually HVAC work is big thing NOW and thus holding off on dash till finished.

The shop frabricated their own hoses and manifold for rotary compressor. New condensor, dyrier and fan but I've not been informed on any brand used,

due to disagreement with second project manager, 5177 was moved to the recently acquired facuiliy. Last week's head butt was over the differance between the rear trunk insert "fitting" over new coponents versus my instructions to modify trunk to allow condensor air flow access engine area. Luckily I talked to Owner and He agreed and though mod was being done and assrued me it would.

Hopefully next update will have HVAC completed and interior going in.

I hate hearing stories like this. It’s your Pantera. You tell them what you want done and they should do it; period, end of story. They are allowed to have their own ideas but if you don’t fully embrace them, they should drop it in a big hurry.

Did they at least know enough to re-route the A/C hoses through the passenger side wheel well? Did they move the drier to the wheel well too?

A few of us, here, have installed Restomod Air heater / AC units. They make a few that are more compact than the Vintage Air units, thus easier to install. That being said, this is not a trivial installation. It’s easier in a late dash Pantera than an early dash car.

Hey Joe

Was it recommended to replace your condenser unit ? Mine looks to be in OK condition and the fan works but I have not pressure tested it yet. I have a new dryer and Sandken rotary compressor already fitted.

The under dash fan unit sounds remarkably similar to a bucket of bolts being poured down a washboard so I have a new one ready to go in , but I wasn't intending to replace the under dash evaporator unit.

Is that the restomod unit you were discussing ?

Any comments on the current recommend TX valve optimal replacement type that they have fitted to 5177 ?

Thanks

Perc

I can't answer . . . those questions are beyond the tech knowledge of the project manager. asking fixed or varible orifice got me silence over the phone. If I get back to shop and have some time with techs, I hope to get answers then.

during a "heart to heart" with Owner a few months back, he stated few clients have knowlede of their car and the others just wanted X brand car. so this why I can't get alone with project managers

Thanks Joe

Yes - when you are shelling out hard earned readies you expect the people involved to know the detail of their craft backwards.

If you hear anything more it would be of great interest.

I can see another (3rd??) full dash removal coming soon for 6997 - my favourite thing ......!!! ![]()

Cheers and hang in there

Perc

There has been no "looking ahead". the hold up on working for the last few weeks has been acquiring the metal stamps to make a replacement YIN tag for the dash! They are ready to install dash, except for that tag.

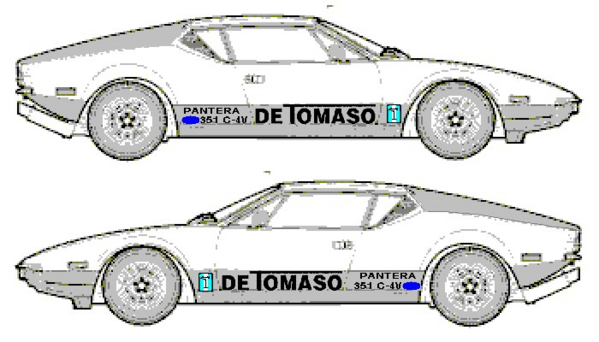

way back (years ago) I posted the way I wanted paint and the graphics.

the Owner suggested "ghosting", AND I liked the ideal. Here is a couple pics I got today.

The "ghosting" look good, to me anyway.

Looks good, Joe!

The only thing that can be leaking where the drain pan is cooling tubes. That’s not any kind of technical challenge to solve. Very minor problem, as you know.

I want to see pictures of the car with you driving, with your curly hair and Glock (holstered, of course!)

Only sorry to see you’ve cut back on your instrumentation!

😎😀

Chuck