Progress is being made! Congrats!

I little up date.

well, the local legionary Cleveland engine builder that had mine for a couple years told be to come and get the pieces as he was no longer able. this was a real disappointment. So I loaded up the pieces and took to the Car Builders shop (GunnerZ) about 4 hours away (Denver, NC.

given that GunnerZ location to all the NASCAR shops, I sure hope they can find an engine builder,

this was the first time I had visited GunnerZ but was impressed with organization and cleanliness.

what I gathered, there was work on all the pieces so assembly should start showing progress some. For example the suspension is on for fitup and comes off for final painting latte

I've lost interest but the shops manager seems to be agressive at finding info and parts. surprising though was they were waiting to get rear axle bearings due to covid related delays

Attachments

When it comes to building a new Cleveland patience seems to be the most valuable item on the parts list.

When it comes to building a new Cleveland patience seems to be the most valuable item on the parts list.

I retrieved my block and components from the first engine builder when there had been absolutely no progress after 3-4 months.

My second engine builder finally delivered my engine to me after about one full year and I’m very glad I pulled a valve cover for inspection of the new roller rockers. See photo. 😳😡

That discovery prompted me to take it to my third engine builder with instructions to completely tear down the engine and check all clearances, and reassemble.

The third machine shop has a engine dyno along with a chassis dyno. The engine dino resulted in 454 hp with 475 foot pounds of torque.

Yours may also be a long journey but I hope your results are as good as mine were. 🤞🤞

Larry

Attachments

Larry, what was the cause of that roller rocker being off, stud not in the head correctly?

Assembly laziness.

CHI 4V heads. ARP studs, Comp Cams guide plates and rocker arms.

The ID of the guide plates was slightly larger than the diameter of the studs and thus allowed the guide plates to be adjusted for correct, or incorrect, positioning.

I had cautioned the engine builder that guide plate alignment was often troublesome for assemblies like this and if necessary they are sometimes cut, properly positioned and then welded to retain correct alignment.

and yet he delivered the engine to me as pictured. 😡😡

The previous photo was the worst example of misalignment but not the only example.

The third shop found they were able to obtain correct alignment with judicious attention to correct alignment as allowed by the ID versus OD diameter differences.

Larry

I'm curious on how the car coming along. Any updates?

I am curious also and CONCERNED.

the excuse is COVID ! very little work (thus no invoices) since the "shut down"

Oh man, sorry to hear that. The extra wait must be excruciating. Hopefully they will be back at it soon. Will be worth the wait! I have plans on taking mine down this year for full restoration at some point. As to not clutter your thread, I may PM you with a few questions when I get there.

Check out Jon kaase racing engines. He is a big Ford engine builder. He also competes in the Engine Masters Challenge and has won many of them with different Ford engines.

I had a discussion with shop building 5177 last week. (I've lost interest

and relying his abilities.) Progress is VERRY slow

The engine builder that abandoned the project a couple years ago had found

"the" ford aluminum intake, in his opinion, better than BT. He was onboard

about making carb base level and re doing studs.

Coming to now. The engine is supposed to be complete EXCEPT, builder

didn't do any thing to intake. During last week discussion with car shop,

he stated he want to "get measurements with engine in" (makes no sense to

me)

So, to my questions and request for info.

Wouldn't the machine shop instructions be mill carb base parallel with head flanges (then Heli coil studs to be square to machined carb base.

Is there anything I am missing? Would anyone know of a pantera shop/dealer

my builder could talk to confirm the intake NEEDS to have the carb base level. AND can be done without taking measurements in the car.

Or some good replies I could forward him

Yes, milling the carb base flat is just as simple as you outlined. It does not require any in-car measurements.

BUT......

AFAIK, the Blue Thunder “Pantera” intake is the ONLY intake that offers a parallel-to-the-ground design when installed in our Panteras. All the other intakes are designed for passenger cars which install the engine at an angle as opposed to the flat installation in our cars. so those intakes have an angle which positions the carburetor flat when installed in a standard passenger car.

The carb base does not NEED to be milled flat for your Pantera application.

Just about every Pantera on the road does not have a flat carburetor base. The workaround is to fine tune your fuel bowl levels to avoid fuel surging out the vent tubes during hard braking. There is also a modification that can be made to the two fuel bowl vent tubes - connecting the two of them with a fuel-safe piece of tubing that has an air vent hole at the highest point.

milling your intake flat is the ideal approach, but it is likely not worth any more grief in your already frustrating endeavor

Larry

As Larry said, there are many, many cars without this modification and they all work fine. Personally, I don't think its worth the effort.

another update . . .

the desired engine builder acquired a Ford Aluminun dual plane intake he thought was the ultimate for street.

NOW, that another (unkown to me) engine builder had to finish up AND the plan to use Throttle body fuel injection, the consecese is don't use a dual plane !

the take off intake was a Torquer. I dug it out of trash and had local guy skim the base level and increased the threaded depth.

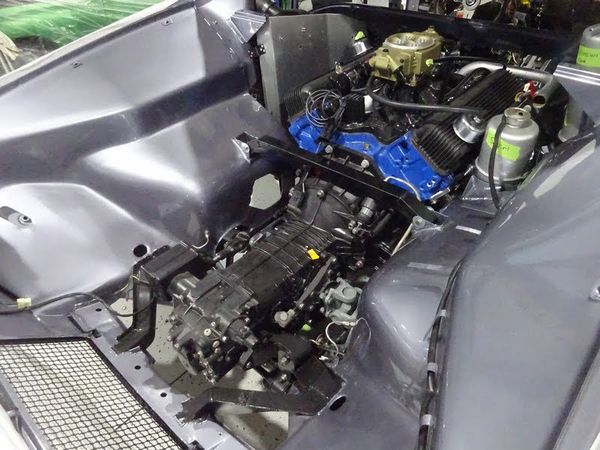

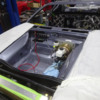

Here is a pic of engine just prior to installing intake. Now the intake doesn't lineup with heads so going to a machine shop for another cut.

Attachments

Looks good! Nice and clean!

So you’re running a flat tapper cam?

Any other exciting mods?

that is the embarrising question. . . I don't know how the engine is built.

I requested the "G Pence, Street" custom grind.

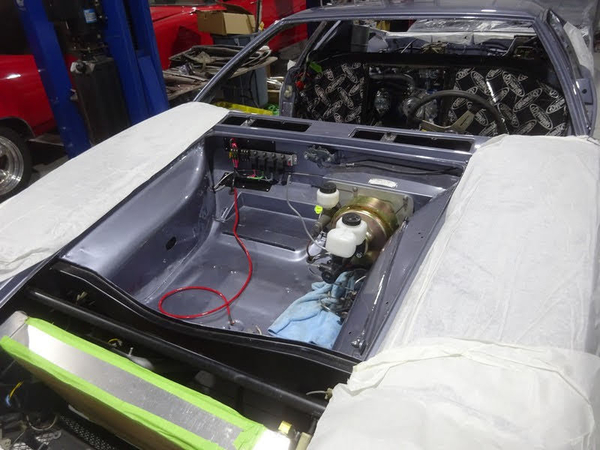

Hey the good news, its painted and plans are to fit into the bay some time soon

the new shop manager, has promised to send photo's from his phone to me in text. I am NOT phone savy and it has taken me all day to get from text to computer to here. And I don't know if I can repeat

Looks like your boys do really nice work!

The black Trans looks really different ( No - I mean nice different !!)- Is it an epoxy or powder coat ?

the "black" ZF is a Ron McCall recomendation and he did when rebuilding it.

Sale point is it will easily rinse clean.

the silver engine bay (instead of black) was recomended by builder, GunnerZ

Percy,

The coating is originally intended for firearms. It is sprayed on and baked ( much like powdercoat but leaves a much thinner coating that is very durable and chip resistant) at 375deg for 1 hour.

Ron

Joe,

That color looks amazing! The work that has been done looks top notch. Curious why they left the metal tabs in the engine bay instead of routing the AC hoses/wiring harness inside the fender well?

You should be excited! It is progressing nicely.

Ron

My question on the coating is how it handles spotting that could be caused by fuel and other chemicals found in the engine bay???

Larry

If this ZF was coated with Cerakote, it’s pretty tough stuff. Engine builders coat pistons with it! I doubt it will stain or spot from chemicals or fluids. I guess time will tell. I used it on my ZF too but mine was done in a medium gray with Cerakote clear coat over it, to make it easier to wipe up any fluids that will inevitably get spilled on it. Most Cerakote coatings do not require heat to cure, so they work well on porous metals and castings like Campagnolo magnesium wheels. When heat isn’t used to cure, you don’t get the out gassing that’s so common with powder coating. I’ve even had Cerakote applied to plastic, to make it look like metal.

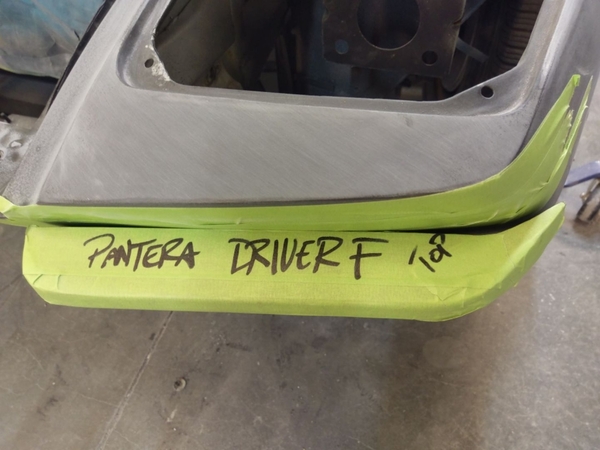

Just a little grinding work and they will be just fine. I had to do the same thing because my car didn't have front bumpers when I bought it and the used set I bought did not fit perfectly.

Well, surely that .4"-ish mismatch is within tolerances lol, j/k. I would have considered the Mr. Fiats at that point, but we all know about hindsight (and for all I know might have been from the same source anyway, there's a lot of that in Panteradom). I truly sympathize. Though being "around the corner" at that point, might not be as noticeable as one would think, but still the principle of the matter.

Nice to see progress continues…. I’m happy for you!

We did this in 4 months but it was just strip and paint. No mechanical! https://www.youtube.com/watch?v=WeGcZWE5ca8

not sure . . . but Yours was my insperation

the sample were labelled Forged Silver (upper) and Phantom Grey (lower)

So you painted using two tones of paint?

did you use the beltline as the dividing line or was it located somewhere else?

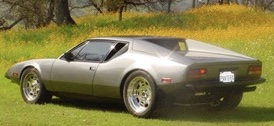

if you study the photo of 2511 you may think it is also painted with two tones, but that is just a function of the surface below the belt line catching the sunlight differently than the top.

Larry

belt line and both hoods are the near black. those photos appear to have the silver darker than the sample.

being optimistic here in preperation to getting 5177 back.

what is the opinion of using the VIN in the license plate. I was thinking

THPN5177

(NC allows up to 8 charectors)

You can save a bunch of property taxes by licensing it as an antique. My taxes went from about $100 to $1200 over the course of a year. Of course, you're in a different county. For antiques the assessed value stays at $500 for the life of the car plus you can put on antique plates on it as long as you have a valid registration and carry the valid tag with you. I don't believe you can customize antique tags though.

Looks like some real progress.