I have -4066. It is an early '73. It came with the internal fuel filler.

I basically did the same thing that you have except I used the factory parts for the "can" and the filler neck. Wilkinson had them and that's where I got them from.

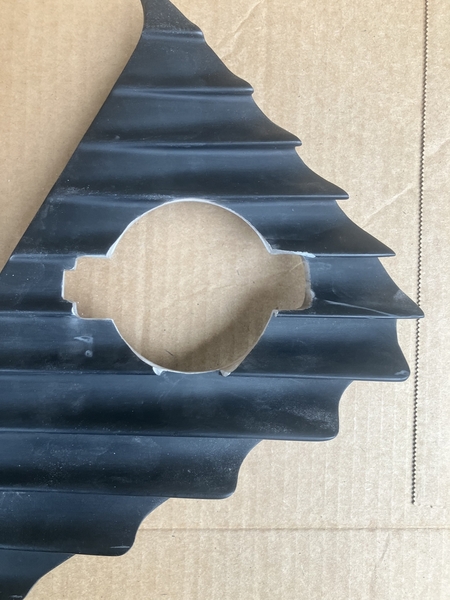

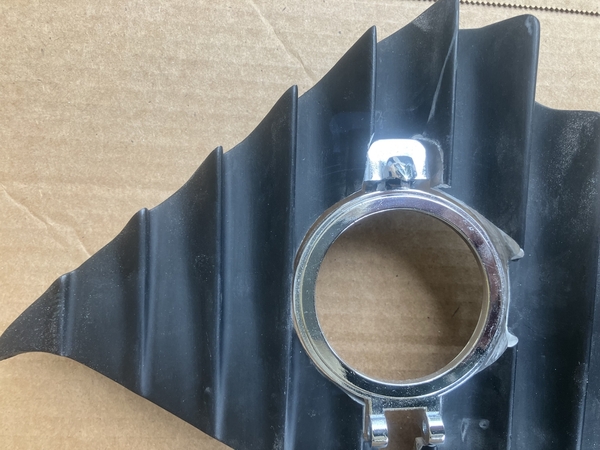

I had gotten the exterior hinged factory grill from him as well but the way that I use the car, it was still cumbersome.

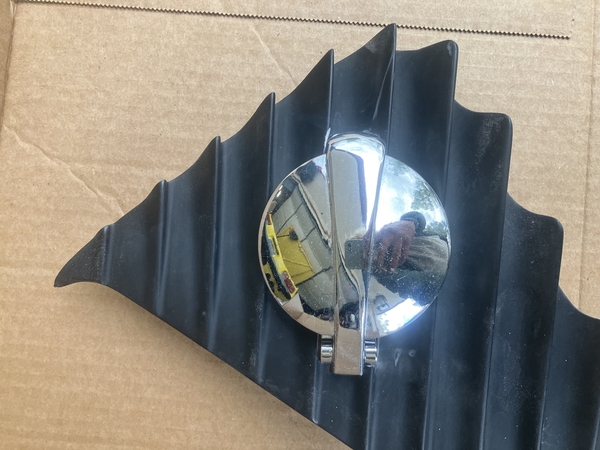

I had the idea of the Cobra external cap but I chose the SC version. At the time Contemporary Cobra was 15 minutes a way from me and I bought that cap from him.

It's a big sucker and I considered notching the gills as you did but because that thing is a casting of unknown strength, I just opted to not notch it.

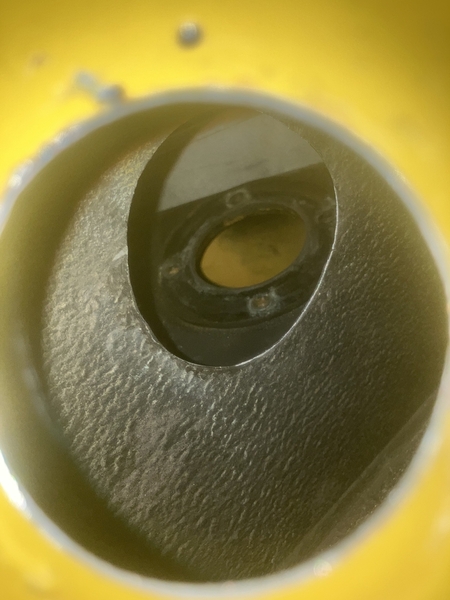

I wound up drilling out the original gills with a hole saw as you did and that was a simple task since the casting is so soft to begin with.

I am happy with the results but you have reminded me of considering the notches to lower the profile. I'll look at it again since you have successfully done it but I'm still not confident that it is not going to leave too little of the grill for comfort?

Are you guys sure that those studs unthread from the gills?

I used the long drill I had to mark the spot with paint … the angle of the inner fender didn’t let me drill through in one go!

I used the long drill I had to mark the spot with paint … the angle of the inner fender didn’t let me drill through in one go!