I wanted to start a new thread away from my "Ooops" post detailing my engine swap to cover this as I can't recall any such topic!

My intention is to be able to use this as a dumping ground for information such as head to header flange gaskets, outlet flange gaskets, issues with any particular type of header...

Here are pic's of some original headers and heat shields that I bought years ago from a guy that had a Goose, a Vallelunga, and a couple of Panteras....all red! These were parts that he bought from an unknown car that was being cut up and parted out....

Left side:

It is absolutely amazing how much the builders flattened that front tube!!! It seems like it is only about 1" tall (rectangular shape now!) from the modification. A LONG way from round....

Right side:

Note the hole in the rear tube...I was really paying attention when I bought these(!)...but then the hole may have been covered by old rusty metal and only was knocked out when I started banging them around!

Here are some shots of the RH side installed showing the relation ship of the flange to the rest... Note that these flanges were made "adjustable" fore-aft, by someone...the tubing has been cut off, crudely stretched, notched, and or shrunken...and now slides over the top of the main part of the header assy, held in place with a muffler clamp. Not a terribly good seal from what I see..... I don't know if this feature is original or not...

All that jagged metal you see inside the flange, is old header metal that is not shaped for optimum flow....! Like I said, a pretty crude job. You can also just see the holes in the main tube where the down tubes dump in....no tri-y's here! Not sure what you would call it! Four into one? Hmmmm....

This last shot shows the same cardboard template that I used to determine fit between the two types of aftermarket headers that I have. The flange location is about a half inch further away from the frame, and about 1" higher than these other ones. (I will post pic's of the other ones when I have a chance....they're in my "Ooops" post too...

Replies sorted oldest to newest

About $4 each, may need trimming on inside of hole (oblong it) to fit, depending on flange.

ROL# EG24154

Felpro 60672

Fits 34 Hyundais from 96-99

25 Nissans from 87 to 93

48 Renaults from 81 to 87

Not terribly popular vehicles....but get'em while you can!

Steve

I am guessing that the first type is the aluminum looking ones. They have evidence of contact with the upper suspension arms. One is notched for smog tubes...the other not.

Second set is the black set, and appears to be later, in that they are modified to clear the suspension arms....however, the fit around the bolt holes (to the heads) is horrible and required a LOT of malletizing to get them to accept a bolt without having to loosen all 7 other bolts to do so!

Note the difference in the flange area of the collectors. Black set looks like a cut off cherry bomb muffler of sorts, while silver set has more of a tapered cone into the flange...

Note: All pictures from here on are with chassis "loaded" and not with wheels hanging in the air, so that suspension is shown "at rest".

First is a shot of the right hand silver header installed.

This side fits well.

This shows the relationship to the frame etc.

View from a little further back:

Beginnings of a template to show position.

Note cardboard up against frame and mark against weld...

Black header installed on RH side. Other than noted issues with cramped bolts..fits fine.

Flange view:

Further back:

Template shows difference in position of flange.

Pictures of LH silver header installed.

This area was REAL close...

Worked on it with a body hammer until I cracked the weld....welded it up...filed it down and had the thickness of a round pencil for clearance!

Flange view:

Mufflers from Mangusta Int'l, copies of the Ansas in stainless. These are natural finish as opposed to painted or ceramic coated. ( I still may send them out for that....)

Working on hanger dimensions now.....

Will update as I get materials and dimensions.

Steve

The manufacturing strategy by Ford certainly could not follow the low volume cottage industry approach used by DeTomaso on the Mangusta. For much higher volume, the engine and transmission were not a problem. Ghia had probably never made a vehicle in the numbers that Ford planned for the Pantera. As a result there would be so many engineering solutions on the Mangusta that were unacceptable to Ford that everything had to be challenged as a new car was conceived. I suppose at the same time DeTomaso wanted a car with a connection to the Mangusta as he saw himself building a company to compete with other prominent Italian makes.

The Pantera in the end was driven by functional changes as well as basic architectural criteria that resulted in a very different looking car.

The Mangusta was extreme in it's seating layout, lowness to the ground and construction. Ford engineers I am sure were horrified at it becoming a Ford product, that dictated the criteria changes effecting design, engineering and manufacturing.

One of the few, and surprising, items left as basic architecture to the unibody/frame layout to be used on the Pantera was the rear bridge.

On the Mangusta it represented the weak point in the chassis that prevented the car from handling well, making it very tricky during high speed cornering. An additional smaller bridge was added(my guess), as a fix. Both bridges are linked to the sides of the rear frame with single bolts that allowed a hinge like response to side forces that came directly into the frame at that point from the rear hub carriers. The bridge was soft mounted to both sides of the frame and the transmission hard mounted to it. All other mid-engine cars I have looked at do the reverse, hard mounting the bridge solidly to the frame and soft mounting the transmission to it. The small rubber mounts allow the bridge to also twist under wheel input.

Ford also used high volume techniques in the interior to take the hand work out of the car.

Weight was reduced in the all steel body by making the car narrower. This also helped get the side windows down. Engine accessibility was enhanced over the Mangusta by changing the rear compartment aluminum engine covers to a single piece without the glass pieces and central hinge bar.

On and on, many more details I am sure reduced the cost although weight ended up about the same as the Mangusta.

Remember also at that time with the introduction of so many mid-engine cars that the Chevrolet Corvette, being rear drive and lower in cost than the Panters, was criticized for being old fashioned. The Corvette almost was discontinued a couple of times but remained to experience the current success that it now has, with rear wheel drive.

The Pantera could have become a sales success if Ford had possibly applied the cost saving techniques to a lower volume car that could have been evolved both in style and function. In the end I think Ford just did not have the patience for this kind of product.

Dick Ruzzin

...correction more than 2-1/2 years!

I guess I need to put the pictures in....that I put in the "other" post that derailed my efforts here..... Stay tuned!

Damn......I knew I forgot to fix something!!!

All those pictures went KABLEWIE....when Comcast dumped picture hosting.... I need to re-edit all of those pictures and posts....one picture at a post I guess....

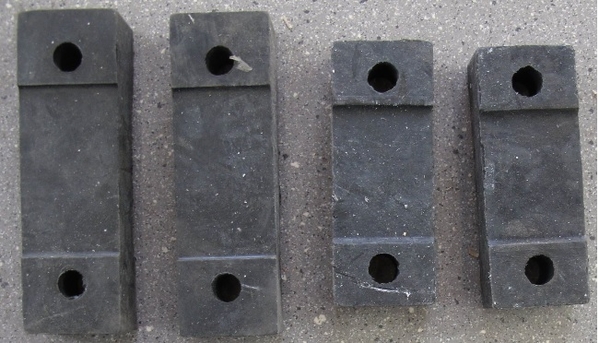

Lee, I believe I got the metal parts from Wilkensen, as Pantera parts.

I bought some rubber strap material in the proper thickness and did a DIY hanger along with the metal reinforcements for the holes!

Used a wood bit to cut the holes....was interesting!!!

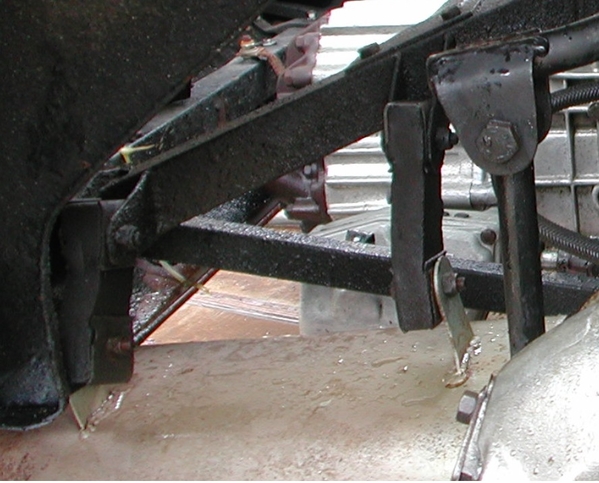

I don't know why the rear strap appears to line up perfectly and the front is way off. Not sure if the mount was re-welded in a new position......would NOT surprise me if that was the case!!!!

BUT, you are correct, the straps are the same as a common car.....Alfa...Fiat..... and there is a short and a long version.

Now, if I could just recall where it was that I saw that info.......CRS is a beyatch!!!!

Cheers!

Steve

Attachments

Pinning down these Goose parts is never easy

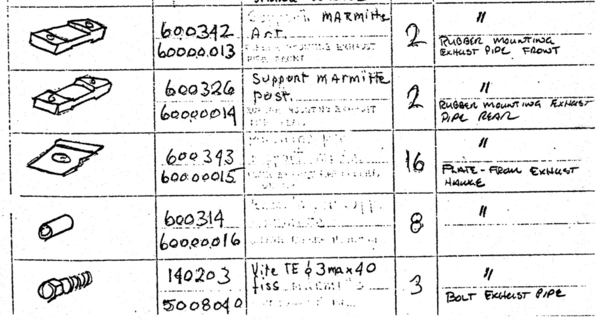

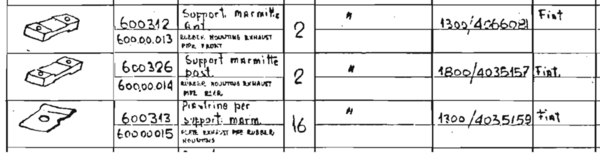

Oh, the answer was always there: the Mangusta Parts manual that Bosswrench scanned and posted on the POCA website shows the fiat 1300/1800 part numbers for both the short and long hangers, both are still available;

4066081 long front

4035175 shorter rear

Still, this doesn't mean a perfect fit--at least, it seems the Ansa DT0127 and DT0137 Mangusta mufflers have a shorter front strap, either/and the Hall headers I have position a little lower (even though I bought this combination from Hall in 1985). Good news, adjusting the strap is easy enough.

You may have seen that "Ansa Classic" will make you original headers or mufflers, each for about 2000 euros each...I can't find it now, but CarID had Ansa mufflers for about $750 a pair, apparently USA made with polished stainless (instead of chrome) tips.

For the life of me, I cannot find gaskets on the shelf that fit...I'm still using ones I cut by hand--Lee

Attachments

Just realized my copy of the hand drawn part list doesn't have the last two columns shown there...lots of useful data cut off for some reason. So Jack, thanks for all the work making good copies available, and Lee thanks for the head's-up!

Steve listed the following collector gasket # some years back and it looks to be still valid: ROL EG24154. The disadvantage he noted was the bolt circle is a bit small - - - I *think* c. 40mm bolt circle radius is needed for an easy no-fuss fit so this would require some modificaiton.

Trying NOT to go there I ended up going with SCE 4203, all-copper type - good bolt circle size although the main diameter is a TAD smaller than optimal. (Might loose a HP or two due to that....) I can't find 4203 in the SCE catalog on line (!) now but it is still listed at Summit Racing.

I wish Pantera style donut seals fit the Mangusta design. The stock Goose parts might have lined up perfectly but I had to work at getting the flanges more-or-less parallel with all the new 'replacement' parts fitted![]()

Attachments

Nate, you just found one of the problems with loose-leaf factory sheets masquerading as 'parts lists': individual pages easily get lost. What I'm trying to do in my small way is preserve as much info as possible by spreading it out to lots of available sources. The Forums do much the same but documentation then becomes an individual's responsibility.