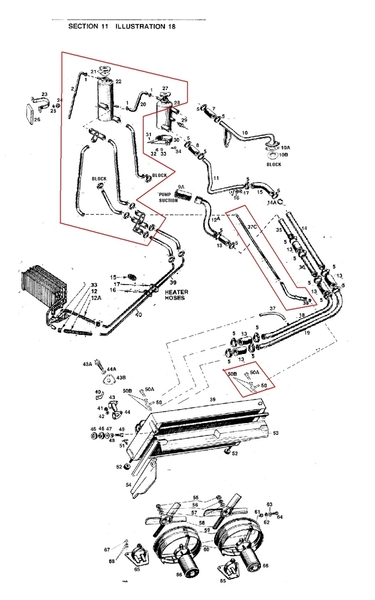

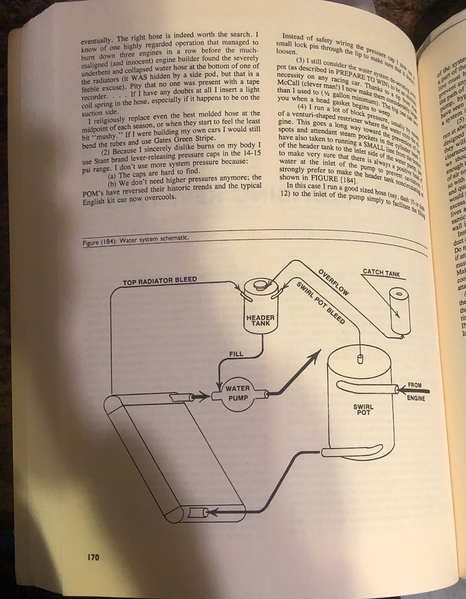

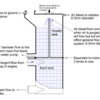

Tackling the self bleeding-swirl tank set up. This is what I have come up with after scouring posts and articles.

I am going to use the original system tank as is as a swirl tank. Install NAPA BK 7031419 4lb pressure cap or cap with no lower gasket (only sealing at the top lip)

Run a 1/4 hard line with hoses from the port in the upper level of the overflow to a nipple in the left upper corner of the radiator.

My concerns are; I didn't read anything stating exactly how much higher the overflow should be mounted. Will my mock up height be adequate?

Any suggestions for a replacement spacer for the void between the flat body and curved overflow tank? Upon disassembly what ever it was, crumbled to pieces so I don't have a sample.

If you see any Red flag areas please let me know.

JerrySr