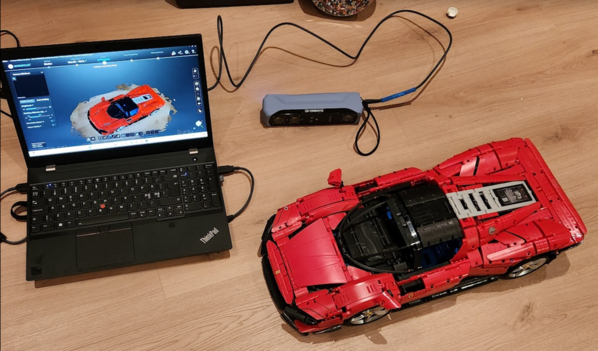

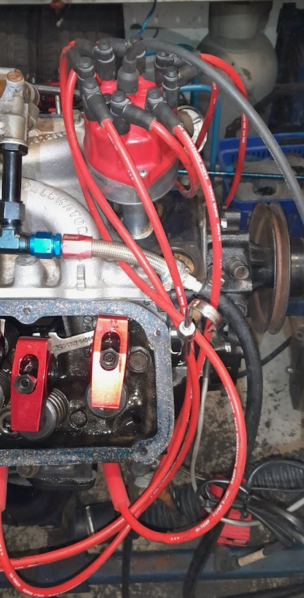

This is the contents of the Ferrari 308 GTB/GTS master cylinder.

It's similar, but certainly not the same. The seal mounts and spring guides are different, and they lack the slimmer, secondary spring.

Seal assembly,

The bore of the master cylinder does however seem to be in good condition, and not pitted like mine.

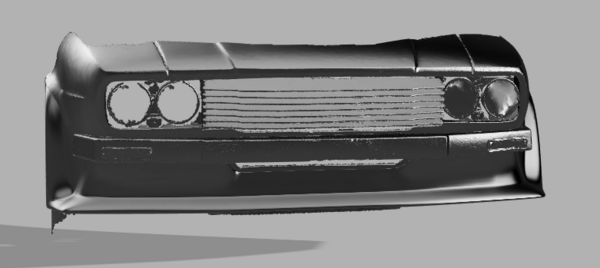

I also did a closer inspection on the original MC, and it seems that I cannot install it in this order,

As the inner piston would hit the end cap and thus not allow proper movement. The inner piston also has a slot for a flat head scewdriver to help align the piston slot to the set screw, which I seem to remember was accessible when the end cap was removed.

Edit: My memory is, as usual, a poor source of information. The inner piston must indeed be positioned as in the above photo, as the adapter plate between the springs will seize on the larger diameter of the protrusion with the slotted head. It seems that the thinner springs purpose is to put pressure on the D-ring seal. The Ferrari 308 seals have a different arrangement to ensure spring pressure on the seals (see separate post below).

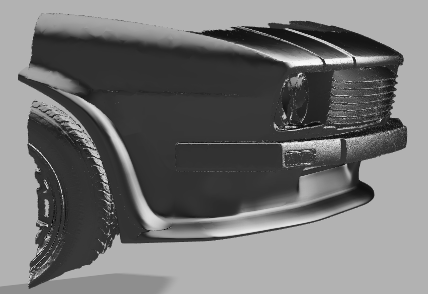

The pittings in the old bore were also on the opposite side of the master cylinder, so it could probably be used with the risk of some internal leakage.

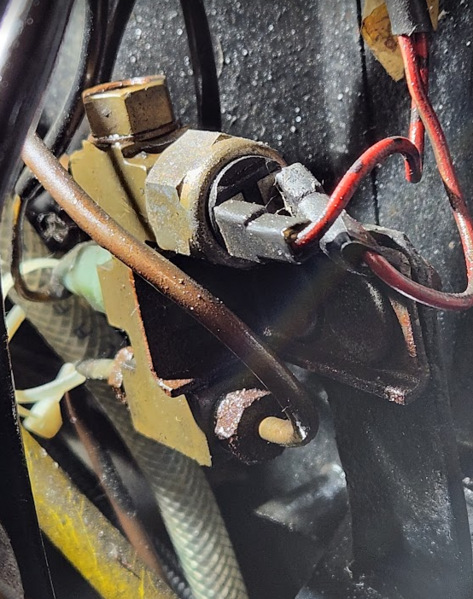

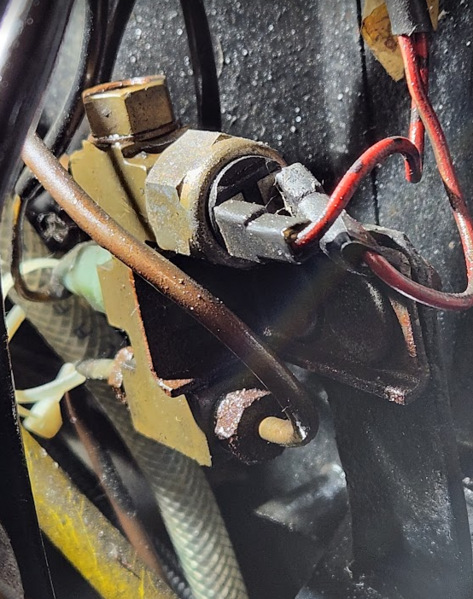

To ad a bit confusion to these last post, Here's the content of the brake pressure differential valve, which you can read about here, GROUP 2B527 - Brake Pressure Differential Valve

I've ordered a spare part kit for it. We'll see if anything fits.

1970+ Ford Disc/Drum Brake Pressure Differential Switch Kit