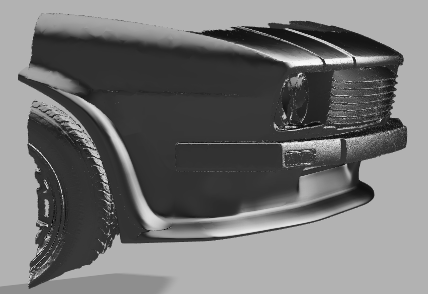

I started dismantling the drivers door doorcard, as this is the one in worst condition. My initial plan was to preserve as much of the original leather as possible, but that may change down the line.

I reached out to Colourlock.no (Car Spa in Norway) for advice regarding the concervation of old leather, as well as the proper method to clean it, without damaging it. The first reply I got was "reupholster. Black mold can't be removed" and thats it. Not a very satisfactory reply, and it does not address the parts of the leather where no mold is present.

I then reached out to their central location in Germany, where I got this recommendation: "use 50/50 water/vinegar to clean the interior" and thats it. No mentioning of their own producs. Which I must say that I find a bit peculiar. They did however shed some more light on why it's hard to remove black mold, with a rather thorough reply;

There is no general answer to whether mold infestation can be eliminated with cleaning and care products alone, or whether a new upholstery including replacement of the upholstery material is necessary and depends on the length of time the leather has been exposed to the unfavorable environmental conditions.

A little mold that appears on vintage car seats after a few months can usually be removed using simple means. However, sets where the mold has spread over several years are rarely available. The reason lies not only in the usually large-scale visible disfigurement of the leather - the entire inner core of the upholstery is usually also covered in mold threads. Even after intensive external processing, any stress on the upholstery, such as sitting on it, causes the effect of a bellows: the mold spores are blown into the interior along with an unpleasant smell.

It is then not a solution to try to overlay the smell with other smells. You then only get a mixture of the perfume used and the smell of mold. The nose is then even more irritated. Such serious cases can only be solved by having the upholstery core and leather completely replaced by a saddler. In this case, the upholstery core cannot be satisfactorily washed or recycled, which would not be of any financial advantage anyway: the leather has already been removed and a new upholstery core hardly increases the costs, but in fact usually improves the seating comfort considerably.

Basically, what I hear is "use the damaged parts to practice leather re-colouring". So that is what I will do. First I have to figure out what colour to use, as I actually prefer the lighter tan/faded brown to the original dark brown leather.

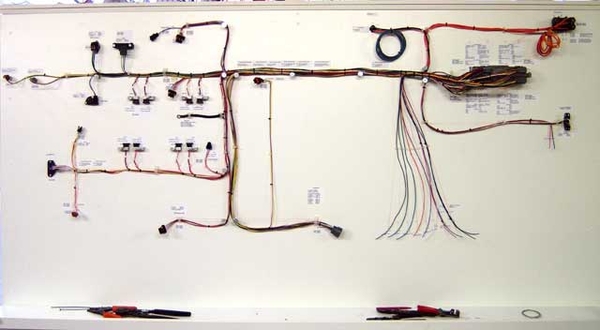

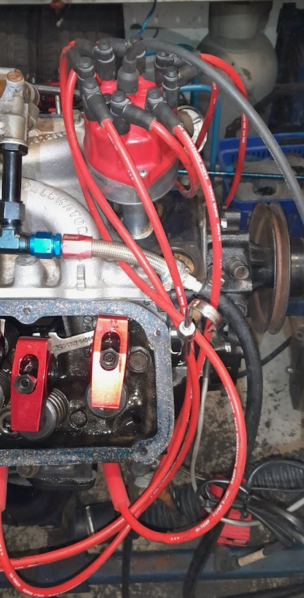

The back side of the door card with vapour barrier in place.

Window seal/strip. Is the rubber gone, or are these just fabric from the factory?

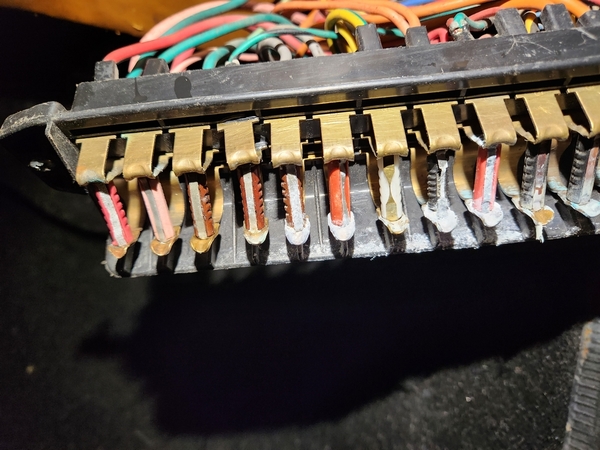

The black strips cover the bolts holding the arm rest/door handle.

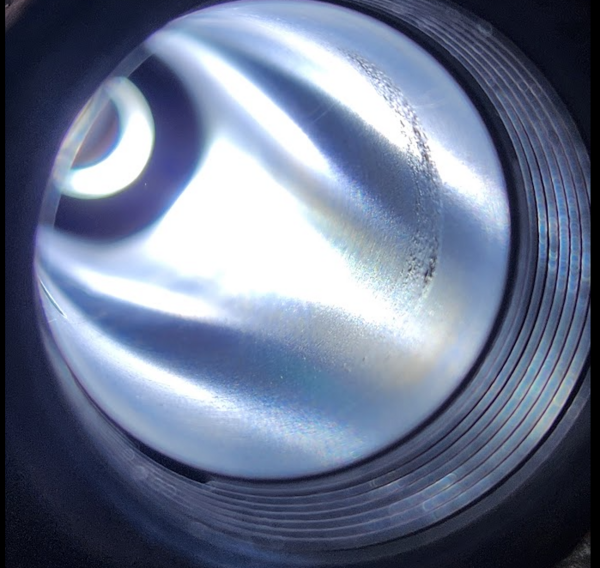

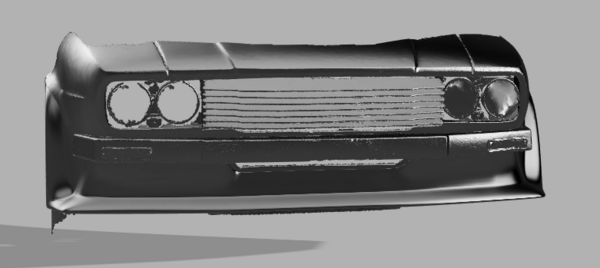

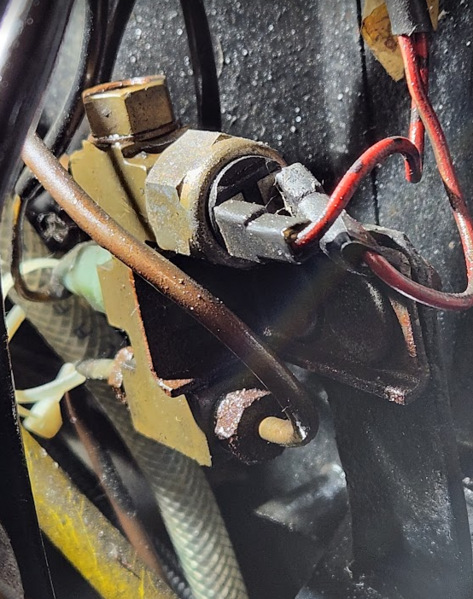

You almost can't tell that the exposed leather has faded. The remaining dark spots from the mold seem to be a permanent discolouration. It will be interesting to see what a respray will do.

Reupholstering parts of the interior is probably unavoidable, but that can be done at a later stage.