Many Panteras have excess rear camber. This is usually caused by flex in the rear monococque chassis, occasionally including broken spot-welds. My '72 was no exception; I fixed it completely by throwing away the stock bridge-style upper bay-brace and used a straight adjustable Hall bay-brace. The important feature of the Hall bar is, the ends protrude well inside the brace mounts. Since the mounts are actually weldments attached to the upper rear shocks and upper subframe on the other side of the inner fender panels, getting the brace-bar ends further inside the weldments, the bar once installed does NOT move under cornering forces. The thin, flimsy mount-tabs are then used only to retain the bay brace in the weldments, not attempt to absorb cornering forces. To make matters worse, the tab holes are oversized and slotted!

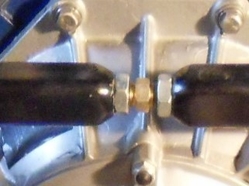

The mechanics of using Hall's adjustable brace bar is to jack up the rear until both rear wheels are off the ground. Install the bar and tighten the central clevis 'firmly'. Lower the car and see where your camber is now. If its still way-negative, take no more than a half-turn more preload in the clevis and tighten the lock-nuts. Do NOT add too much preload to start with. Drive the car for a hundred miles or two, then check your camber again. If it's still excessive, jack it up again and tighten the clevis another half-turn or so, retighten the lock-nuts and drive it some more. I realize this does not read like a recipe for exactly how much pre-load you need at each point in time. Sorry- that's not how things work.

What we're trying to do is slowly tease the whole spot-welded rear body/chassis back into proper alignment a bit at a time. Trying to adjust it all out at once will almost guarantee that a fender panel or even the roof will buckle, forcing some seriou$$ bodywork to correct. Be patient. Over a 6 week period, I was able to force my chassis back from over -2 degrees negative camber to + 1 degree positive, without any panel buckling.

The camber bar clevis adjustment will force the body/chassis into new positions, then it will slowly relax into the new position with little bar preload remaining. That's when you realize that 'things' back there are in fact moving to new locations. Note this will NOT happen with a stock bay-brace or one of the pretty aluminum adjustable bars with short ends that do not fit snugly into the stock weldments. The mount tabs will instead distort and most of the bar preload will be wasted. Can't predict what the result might be.

Did I mention my wife and I both regularly drove our car for decades in autocross, open-track and often as a daily driver on bumpy local streets after my 'adjustment?' I've owned it since 1980 and it's NEVER been babied. But with that preloaded adjustable bay-brace, rear wheel alignment is still within factory spec after almost 30 years, and the body is still straight. I use stock a-arms front & back, upper & lower, with poly bushings and ball joints. Expensive rear tire wear (10" Campys in back) is near-even side-to-side. I am not a magician; It CAN be done if you take the mod' slow 'n easy! Worked for me in the previous century. Good luck.