Tiptop, that is very interesting. So I did just try on the rear wheel. So far I only had looked at the front, and figured the rear would be the same. But I was wrong, as I often am.  With the stock studs I got 7 1/4 turns with finger tightening alone. So it appears that the rear studs don't need to be replaced. So I compared the back of the front wheels to the rear wheels, and the fronts definitely have a deeper stud hole from the rear, which gives it less exposed threads. Looks like I only need to change the front studs after all, which is a much easier task.

With the stock studs I got 7 1/4 turns with finger tightening alone. So it appears that the rear studs don't need to be replaced. So I compared the back of the front wheels to the rear wheels, and the fronts definitely have a deeper stud hole from the rear, which gives it less exposed threads. Looks like I only need to change the front studs after all, which is a much easier task.

Panterapatt, the pressed in steel seats are definitely 60 degree angled both for the front and the rear.

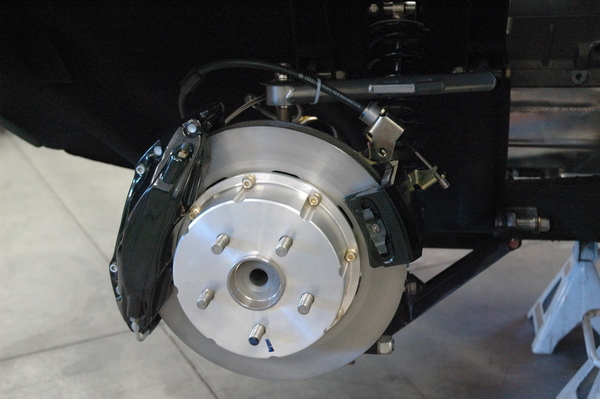

This project just became a whole lot easier. I am still going to invest in the Wilwood brakes.

Last night I finished installing all new brake lines and a new brake proportioning valve I bought from Jerry at PIM. Everything looks so clean and tidy now.

Time to order some front studs, replace them, and put these bad boy wheels on and take a few photos.