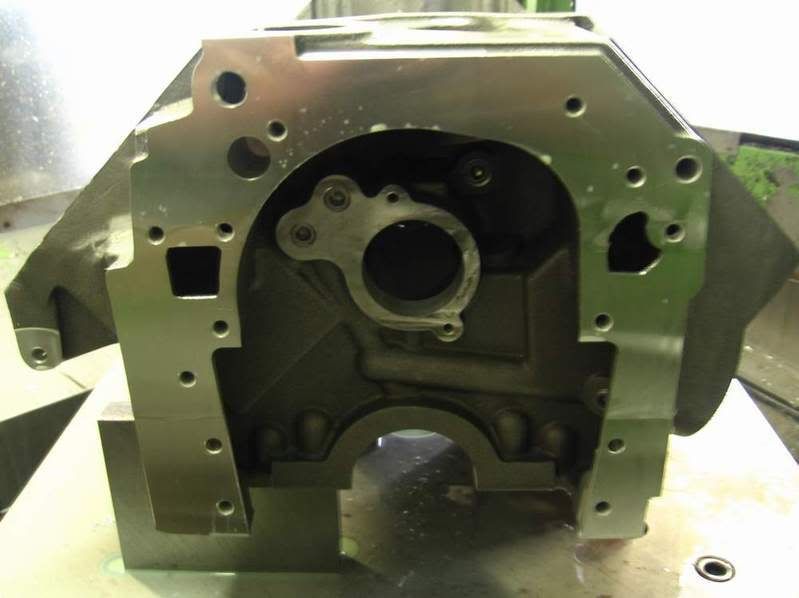

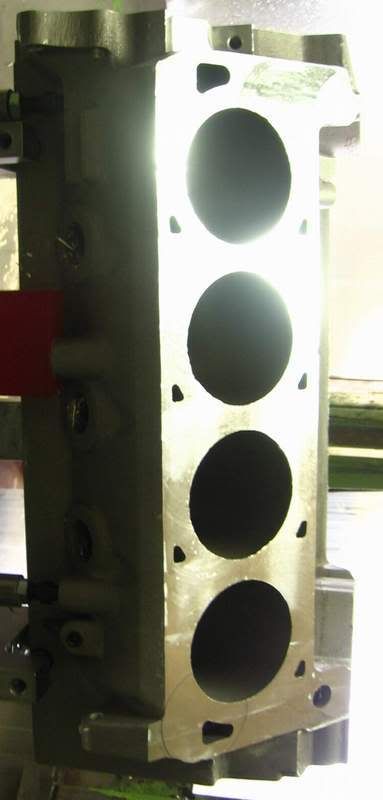

My name is Tod Buttermore and I was invited to this forum by George Pence, a loyal backer of my new 351C project. For those interested, I am about 4-8 weeks away from casting a sample block or two. I intend to have a couple of samples machined and built by a reputable builder, make any alterations that may need done and then start to fill initial orders of the 20-30 anxiously waiting Cleveland fans that have borne with my efforts for the last 9 months or so. If you would like to know more I can post some more info here, or if you would like to have your name added to a list of prospective customers email me privately.

Thanks,

Tod

Original Post